TM 55-1510-215-10

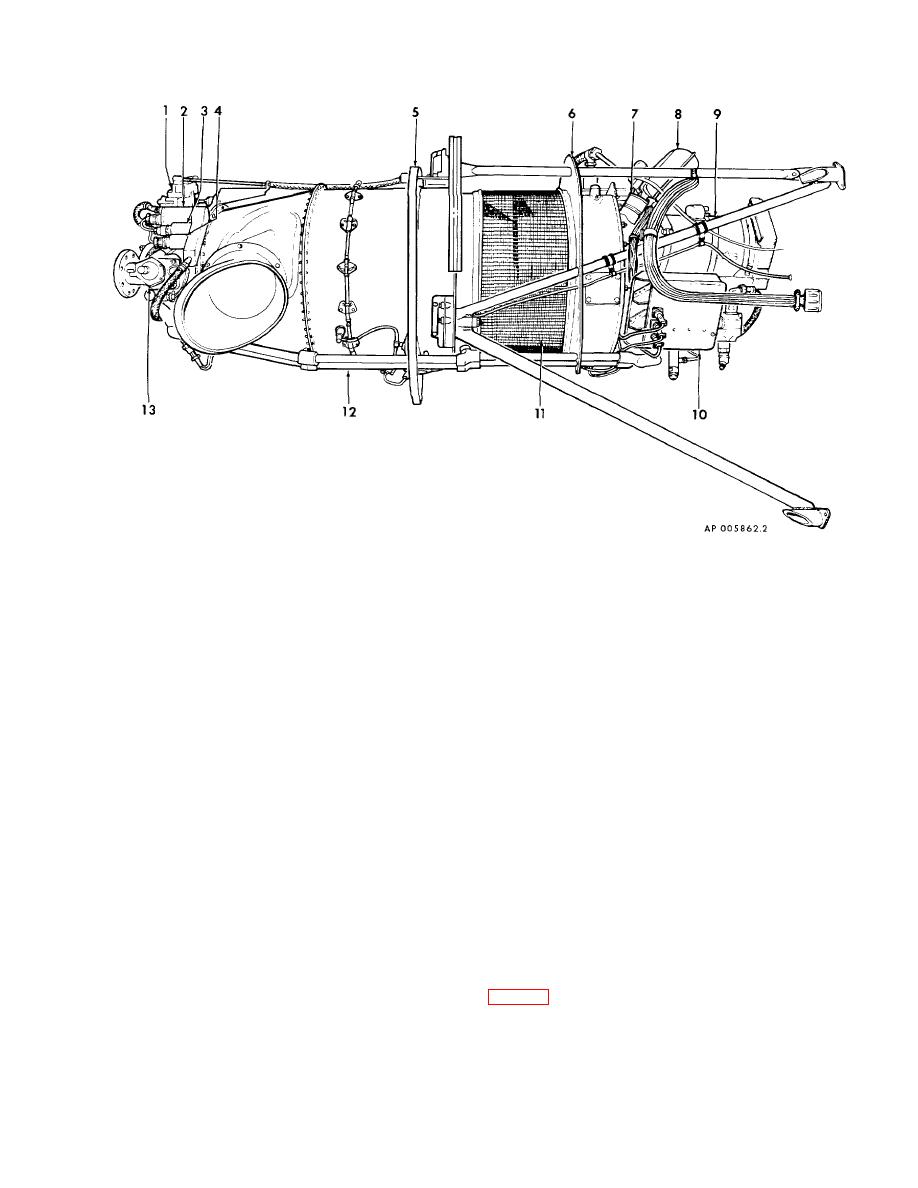

(Figure 2-10 sheet 1 of 2)

(Figure 2-10 sheet 2 of 2)

1.

Propeller governor

8.

Oil-to-fuel heat exchanger

2.

Torque pressure transmitter

9.

Starter/generator

3.

Auto ignition pressure switch

10.

Ignition regulator box

4.

Auto feather pressure switch

11.

Air intake screen

5.

Center fireseal

12.

Oil scavenge tubs

6.

Rear fireseal

13.

Propeller overspeed governor

7.

Oil filler cap and dipstick

Figure 2-10. T74-CP-700 Engine (sheet 1 of 2)

separate air scoop attached to the lower section of the

propeller thrust is used. This system is for use during

nacelle. Special components of the engine induction

landing operation only. It is comprised of plumbing

system protects the power plant from icing and foreign

which routes engine bleed air through a control valve

object damage.

into the bypass air duct mounted aft of the engine oil

cooler. When opened, bleed air-flow causes an increase

2-21. Foreign Object Damage Control.

in the velocity of the air passing through the engine air

intake. The increased air velocity prevents dust particles

The engine has an integral air inlet screen designed

present in the air from making the sharp turn up into the

to obstruct objects large enough to damage the

engine plenum chamber, forcing them to follow the air

stream out through the bypass duct. The control valve

mounted on top of the bypass duct, is normally closed

2-22. Inlet Air Separator System.

blocking the flow of bleed air. Both engine particle

separator systems are controlled by one INLET AIR

a. An inlet air system is designed to prevent the

SEPARATOR SWITCH ON THE LEFT SUBPANEL

engines from ingesting dust and foreign matter when the

aircraft lands on unimproved runways and reverse

2-15