TM 55-1650-261-40

b. Inspect all components for evidence of corrosion.

13. Cleaning

c. Inspect filter for damaged screen.

a. Clean all metallic parts with dry cleaning solvent

d. Inspect electrical receptacle connector for bent

(Item 1, table 3). Dry with clean, filtered compressed air

or broken pins.

not exceeding 15 psi.

e. Inspect all metallic parts for breaks, cracks, nicks,

b. Remove stubborn dirt or foreign matter from

scratches, scoring, distortion, gouging, or other obvious

external surfaces of slide valve assembly by scrubbing

defects.

with a stiff-bristled brush dipped in dry cleaning solvent

f. Inspect springs for deterioration and damage.

(item 1, table 3). Dry each component with clean, filtered

g. Inspect solenoid assembly for condition of cover

compressed air not exceeding 15 psi.

and wiring for wear and damage.

h. Refer to table 4 for serviceability of parts.

14. Inspection

a. Inspect all threaded components for crossed,

stripped, or worn threads.

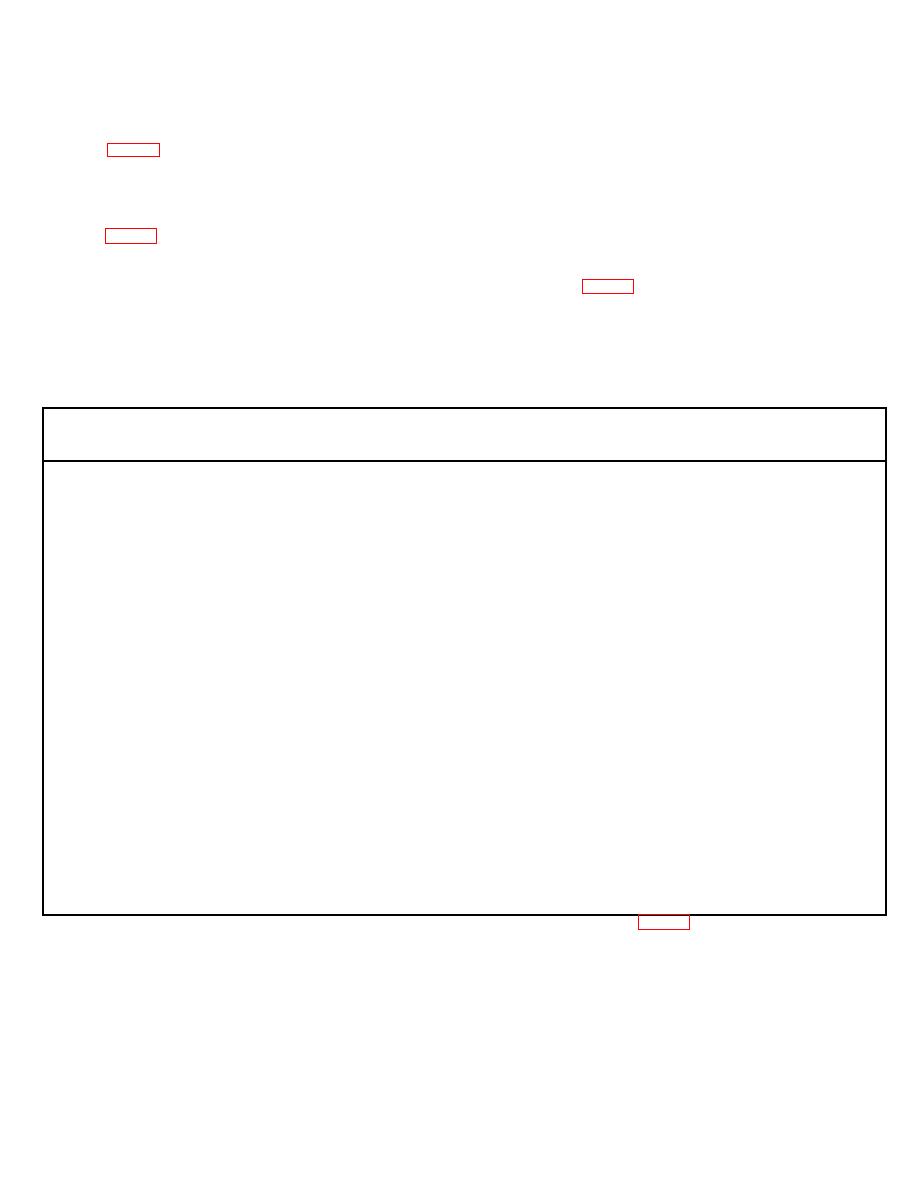

Table 4. Non-Desctructive Test Data

Descriptive

Type of

Fig.. Item

Nomenclature

Test

Procedure

Applicable Defects

3-1

Connector

Visual

Replace if pins are broken or damaged.

3-12

Spring

Mechanical

Replace if damaged or if it does not support

20.7 pounds + 10 percent at 1.255 inches.

3-7

Retainer

Visual and

Replace if OD exceeds 0.500 + 0.005 inch and

Dimensional

ID exceeds 0.374 + 0.001 inch.

3-20

Filter

Visual

Replace if filter screen is damaged or distorted.

3-23

Visual

Replace if case is damaged or if the wiring is

Assembly

damaged or worn to the extent it may impair

proper function.

3-26

Spring

Visual and

Replace if damaged or plating is deteriorated

Mechanical

or if it will not support 3.0 pounds + 5 percent

at 0.226 inch.

3-28

Plunger

Visual and

Replace if OD exceeds 0.4350 + 0.005 inch.

Dimensional

3-14

Pilot Spool

Visual

The pilot spool assembly, spool-plug assembly,

Assembly

and body are mating lap surfaces and all must

be replaced if any of the lap surfaces are

3-29

Spool-Plug

Visual

damaged or scored and will not meet the test

Assembly

procedures cited herein. The reference lap

diameter of the spool-plug assembly and body

3-32

Body

Visual

is 0.625-inch diameter. The reference lap

diameter of the pilot spool assembly and body

is 0.187-inch diameter.

serviceability criteria of table 4.

15. Repair or Replacement

c. Straighten bent electrical receptacle connector

pins with a standard pin straightener.

a. Replace all packings, retainers, gaskets, and

d. Clean and neutralize all areas showing signs of

nylon thread locks.

corrosion.

Note: The age of all packings must not exceed 24

e. Replace all threaded components that have

months from date of manufacture at time of reassembly

crossed, stripped, or worn threads.

of the unit.

/. Resolder all connections, when required, in

b. Replace all parts that have corresponding kitted

parts and all parts that do not meet the

7