TM 55-1650-261-40

SECTION IV

FINAL TEST PROCEDURES

5606 or MIL-H-6083. Filter the hydraulic fluid of all

19. General Test Procedures

foreign matter over 10 microns in size. Conduct tests at

70

room temperature of to 90'F (21' to 32'C) and an oil

Bench-test the slide valve assembly, using hydraulic test

temperature of 70' to 109'F (21 to 43'C). Record the

stand, part No. HA5-1-2-3-5-6-7. The proof pressure test

actual oil temperature during tests.

must be performed first, but thereafter the sequence of

performance of the follow ing tests is immaterial.

20. Proof Pressure Test.

Hydraulic fluid used during tests must conform to Military

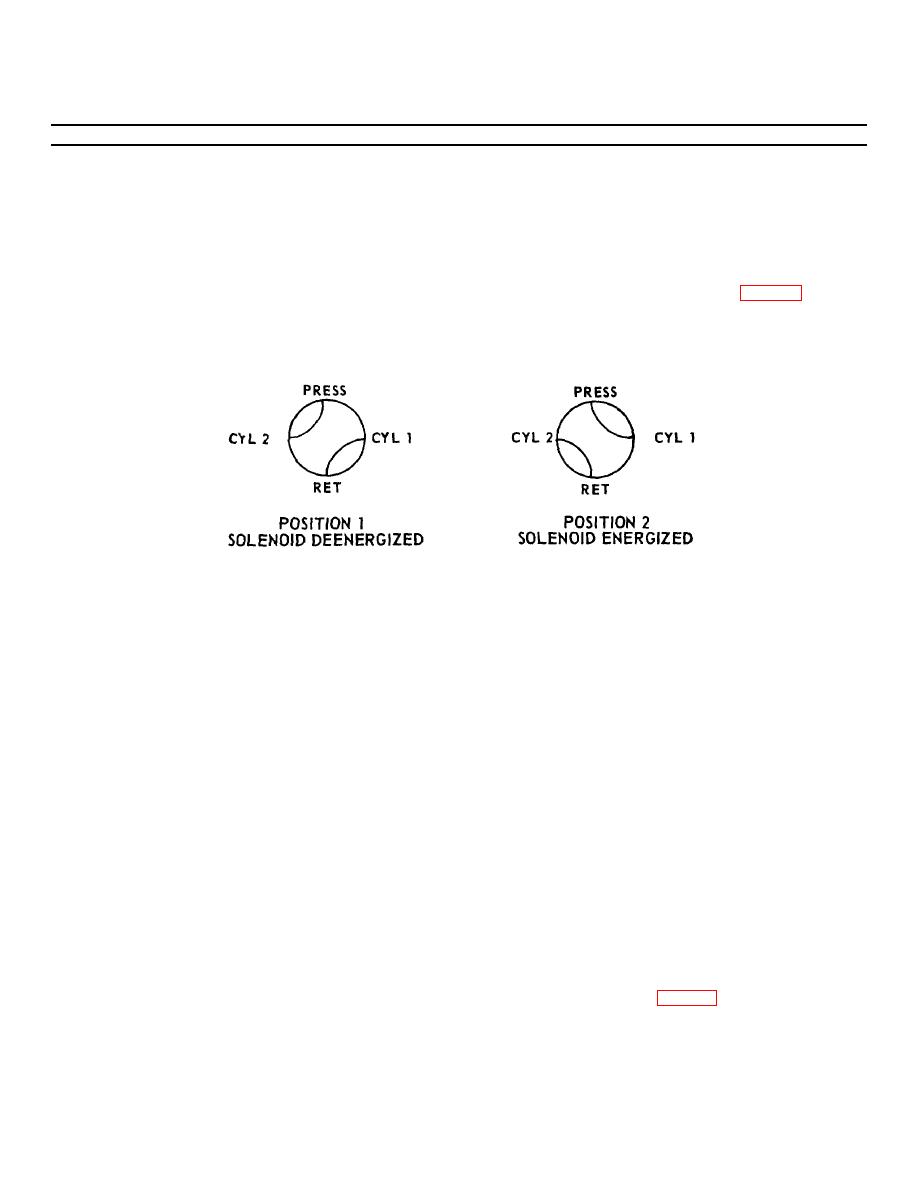

a. Deenergize solenoid assembly. (See figure 5.)

Specification MIL-H-

Figure 5. Slide Valve Assembly Schematic Diagram.

b. Plug return and cylinder ports.

c. Apply a hydraulic pressure of 4500 psig to

f. In each of the above tests, there must be no

pressure port and ;hold for 1 minute. There must be no

evidence of lag or hesitation during actuation.

evidence of external leakage, failure, or permanent set.

d. Remove plug from return port and plug pressure

22. Leakage Test

port.

e. Apply a hydraulic pressure of 4500 psig to return

a. Plug cylinder port 2. With solenoid assembly

port and hold for 1 minute. There must be no evidence of

deenergized, apply a hydraulic pressure to pressure port.

external leakage, failure, or permanent set.

b. Remove plug from cylinder port 2 and plug

cylinder port 1. With solenoid assembly energized, apply

21. Actuation Test

a hydraulic pressure of 3000 psig to pressure port.

c. Remove plug from cylinder port 1 and plug

a. Cap cylinder ports with gages and open return port

cylinder port 2. With solenoid assembly deenergized,

to drain.

apply a hydraulic pressure of 5 psig to pressure port.

b. With solenoid assembly deenergized, apply a

d. Remove plug from cylinder port 2 and plug

hydraulic pressure of 3000 psig to pressure port. Gage at

cylinder port 1 and increase pressure at pressure port to

cylinder port 2 must read 3000 psig.

100 psig. With solenoid assembly energized, apply a

c. Energize solenoid assembly. Gage at cylinder port

hydraulic pressure of 5 psig to pressure port.

I must read 3000 psig, and gage at cylinder port 2 must

e. 'In each of the above tests, combined leakage

read 0 psig.

from open ports must not exceed 20 cc a minute,

d. Deenergize solenoid assembly. Gage at cylinder

measured immediately after selection.

port 2 must read 3000 psig, and gage at cylinder port 1

f. Lockwire screws (2, figure 3) and screws (22) upon

must read 0 psig.

completion of tests.

e. Perform steps c and d above 13 times, applying a

hydraulic pressure of 100 psig instead of 3000 psig.

9