TM 55-2840-241-23

(2) If pointer is more than 5/64 in. (2.0 mm) below 30

degree mark, rerig aircraft linkage to move pointer

closer to the 30 degree mark.

(3) If N1 idle speed did not change, very slowly roll

the twist grip to index mark in the direction of

increased power. No increase in N1 speed is permitted

before fuel control pointer indicates 30 degree as indi-

cated on twist grip index mark.

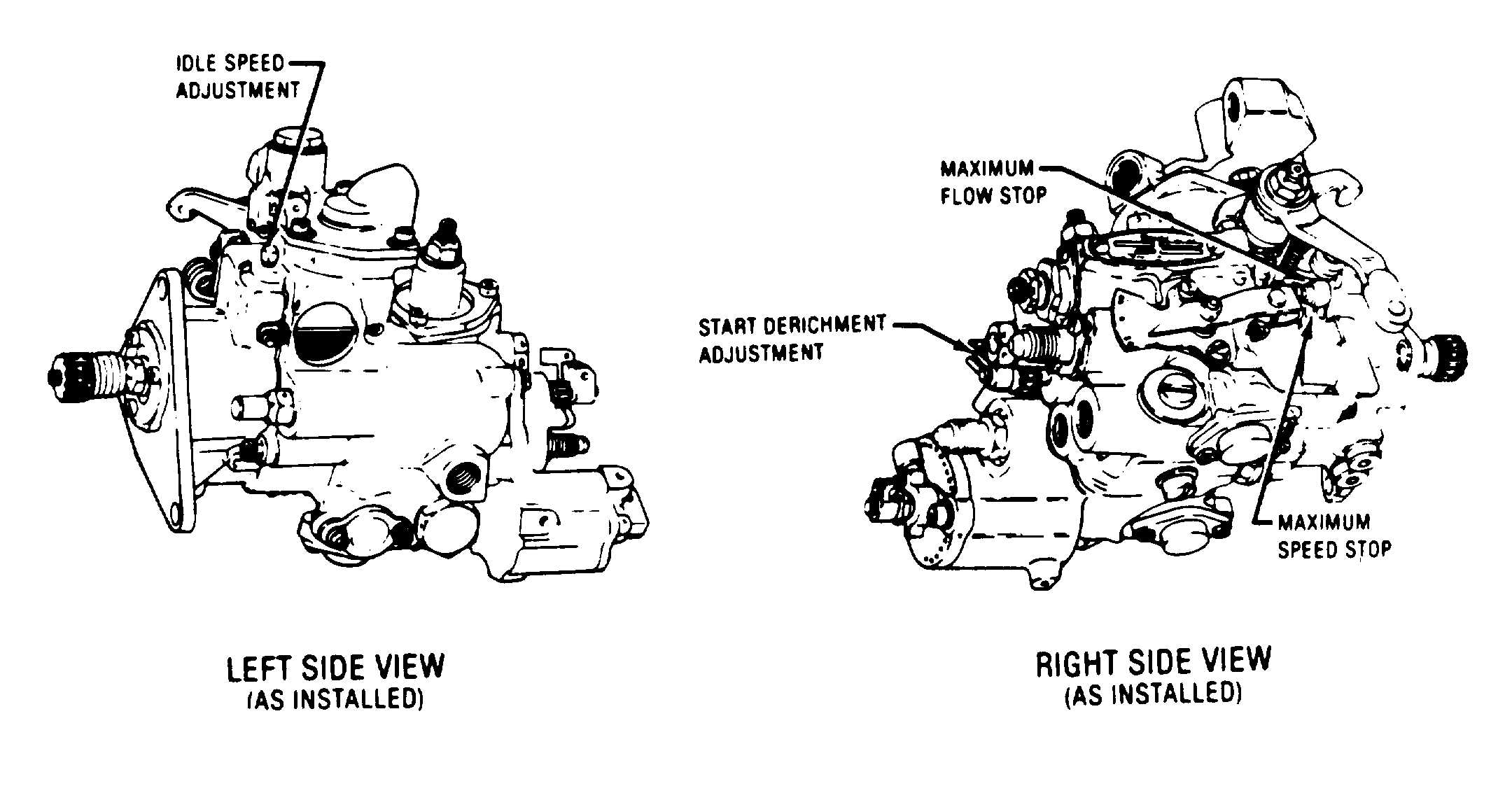

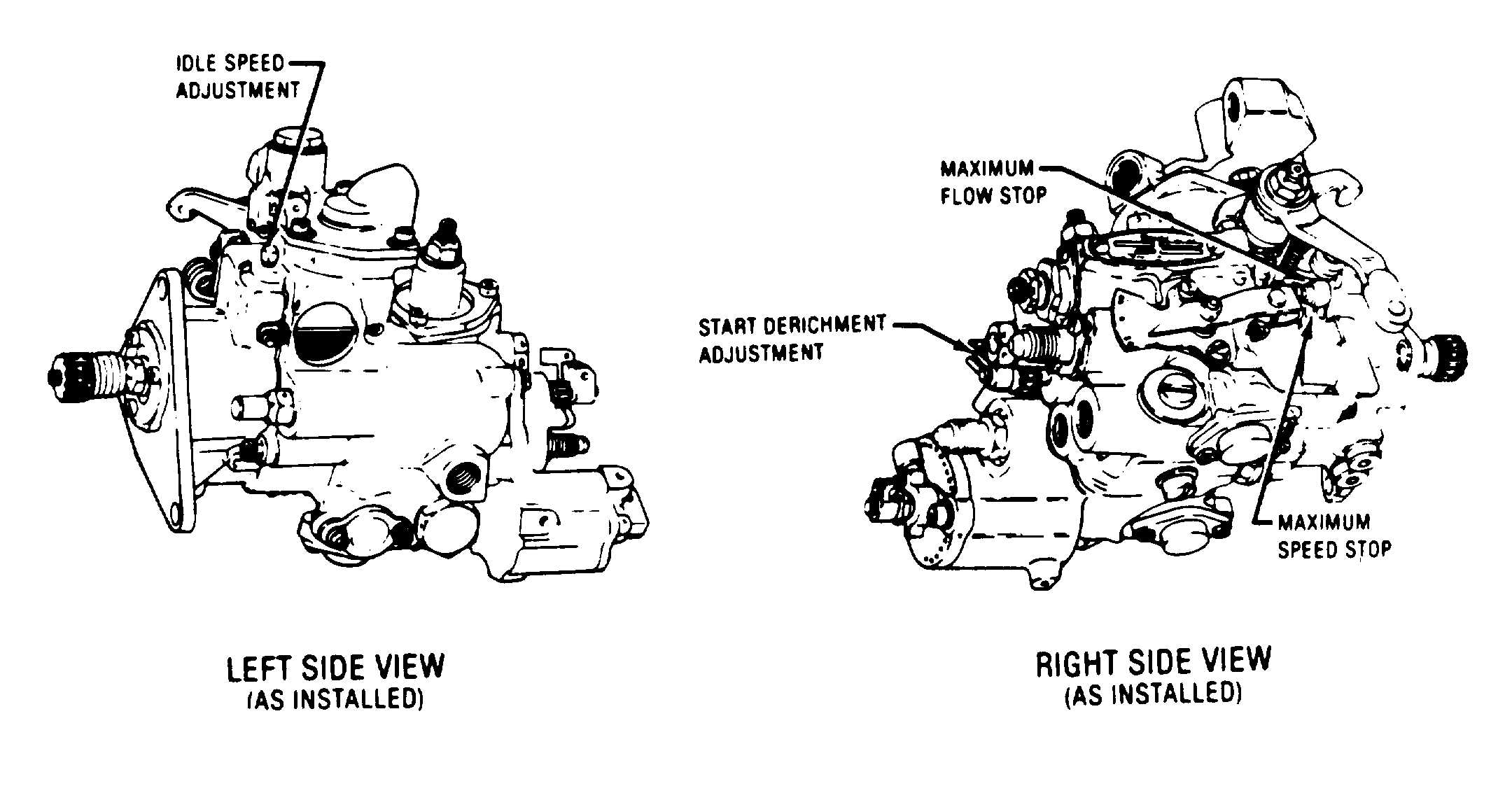

(4) When the rigging is correct, change the idle

speed adjustment screw to obtain a 62-64% N 1 speed

adjustment with generator switch off. Set the idle

speed at approximately 63% N1 to allow for seasonal

temperature changes. (See figure 5-6). Using wrench

6798292, turn the screw counterclockwise to decrease

N1 speed. A 1/8 turn adjustment changes engine speed

approximately 5%. If Nl speed does not respond to the

idle speed screw adjustment, the rigging is establish-

ing idle speed. Rerig is required. If N1 speed does

respond to the idle speed screw, make the 62-64% N1

speed setting. An engine performance check is not

required if the rigging has not been adjusted.

f. Maximum Speed Stop. (See figure 5-6.) Adjust

screw clockwise to increase or counterclockwise to

decrease N1 speed. Do not exceed 105% N1. Check rig-

ging to assure arm contacts max speed stop with twist

grip (both sticks).

N O T

E

Maximum speed stop screw should be turned in

increments of one turn maximum One turn

equals approximately l% N1 speed.

NOTE

If the allowable limit of one of the three main

indicators (torque, temperature or N1 speed) can-

not be reached in flight. readjust the max speed

stop screw. Do not exceed existing torque. tem-

perature or N1 limits.

NOTE

An engine performance check is required after

adjusting maximum speed stop screw (refer to

applicable Aircraft Maintenance Test Flight

Manual). An EPC is required after adjustlng max

speed stop screw or adjustment of fuel control rig-

ging.

Figure 5-6. Gas Producer Fuel Control Adjustments

Change 14

5-10.1