TM 55-2840-241-23

(2) If the filter was not heavily contaminated,

accomplish steps j through l.

h. Drain the oil from the engine oil system. (Refer

to paragraph 5-20.)

i. Fill the oil tank with the desired oil and release

the engine for service.

j. After five hours operation, inspect and clean or

replace the oil filter.

k. After 15 hours operation since oil change, in-

spect and clean or replace the oil filter.

l. Revert to normal schedule of inspection of oil

filter.

5-22. Mixing of Engine Oils.

Do not mix MIL-L-7808 and MIL-L-23699 oil ex-

cept in an emergency. If mixing is necessary, flush the

system within six hours of engine operation, (Refer to

paragraph 5-21.)

5-23. 0i1 Tubing and Fittings.

The tubes used in the oil system are rigid stainless

steel assemblies incorporating permanent fittings.

a. Inspect oil tubes for kinks, uniformity of

diameter, breaks, and freedom from interference with

adjoining structure or other components. Replace de-

fective oil tubes.

b. Inspect fittings and hardware for cracks, cross-

ed threads, obstructions in openings, burrs, or other

damage. Replace all damaged fittings. Replace all

seals, packings, and lockwire when they are removed

from a unit. If cracks in fitting or hardware are sus-

c. Tighten No. 4 size coupling nuts to 80-120 in. lb

and No. 5 size coupling nuts to 150-200 in. lb.

5-24. Magnetic Chip Detectors.

Each chip detector consists of a magnetic plug

with a single pin electrical receptacle. The threaded

plug portion of the chip detector includes a terminal

shaft and. pole piece separated from a magnet in the

plug body by insulators. When ferrous metal particles

are sufficient in size of accumulation to bridge the gap

between the pole piece and the magnet, an electrical

(ground) circuit between the chip detector and the

ENG CHIP DET indicator light is completed.

a. Removal. Remove lockwire and unscrew

magnetic chip detector. Some oil spilling is likely.

Remove preformed packing from plug and discard

preformed packing.

NOTE

When removing chip detector, care should be

taken not to contaminate detector.

b. Inspection.

(1) Visually check each plug for metal ac-

cumulation.

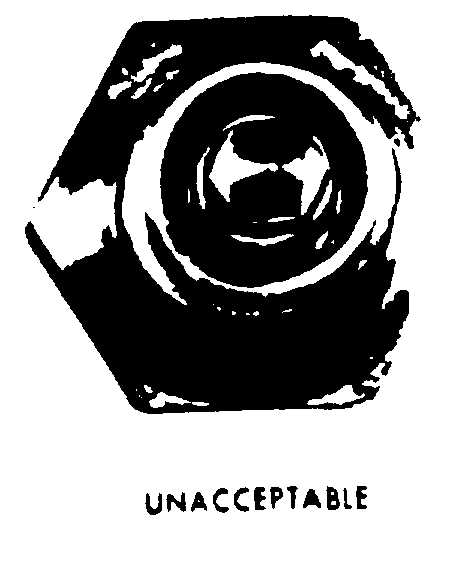

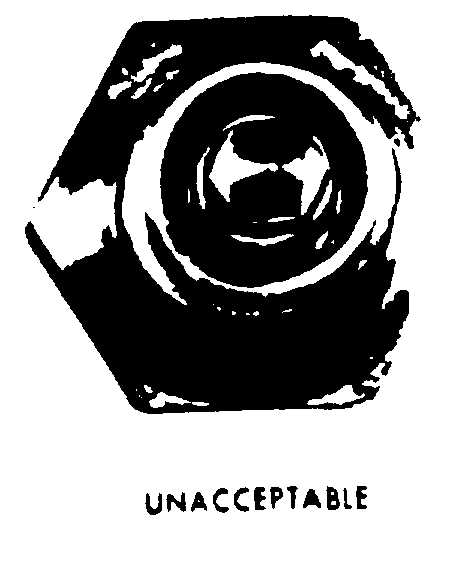

(2) Flakes of magnetic material of 1/16 in. or

more diameter are indications of an incipient failure

and are cause for engine removal. (See figure 5-10.)

(3) Fuzz or hair-like magnetic particles can

normally be found on the magnetic plug and are not

cause for engine replacement. (See figure 5-10.)

c. Cleaning. Wipe chip detectors with a clean,

lint-free cloth.

d . I n s t a l l a t i o n .

I n s t a l l a n e w p r e f o r m e

packing lubricated with oil (item 7, table 2-2) on

magnetic plug. Install magnetic plug; tighten to 60-

80 in. lb and lockwire.

e. Testing—Chip Detector and Circuitry.

(1) Place BATT-OFF switch to OFF and

apply external power.

(2) Remove chip detector.

Figure 5-10. Particle Accumulation on

Magnetic Chip Detector

Change 23 5-17

254539

pected, refer to TM 1-1520-254-23, Technical Mnual

Aviation Unit Maintenance (AVUM) and Aviation

Intermediate Maintenance (AVIM) Manual Nondes-

sructive Inspection Procedure for OH-58 Helicopter Series.