TM 55–2840–254–23

Change 6 4–503

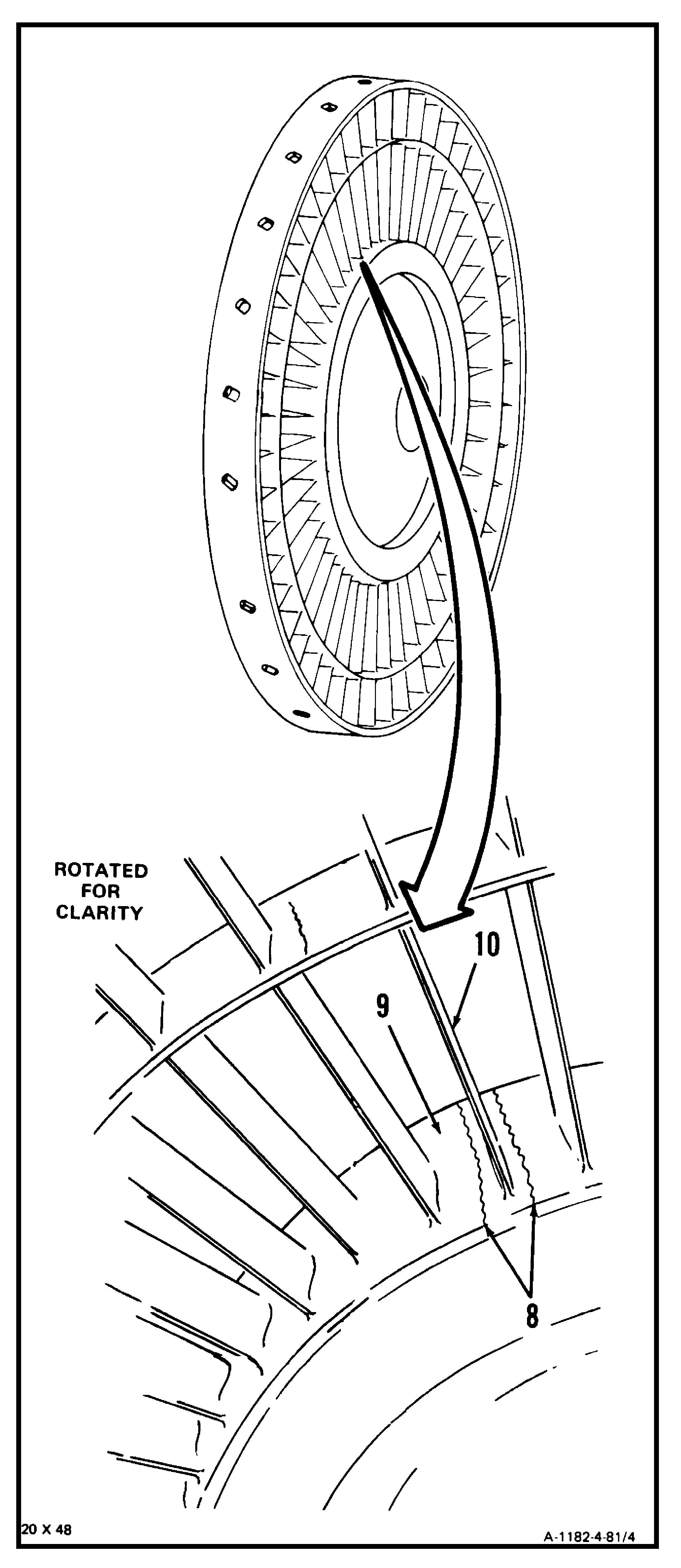

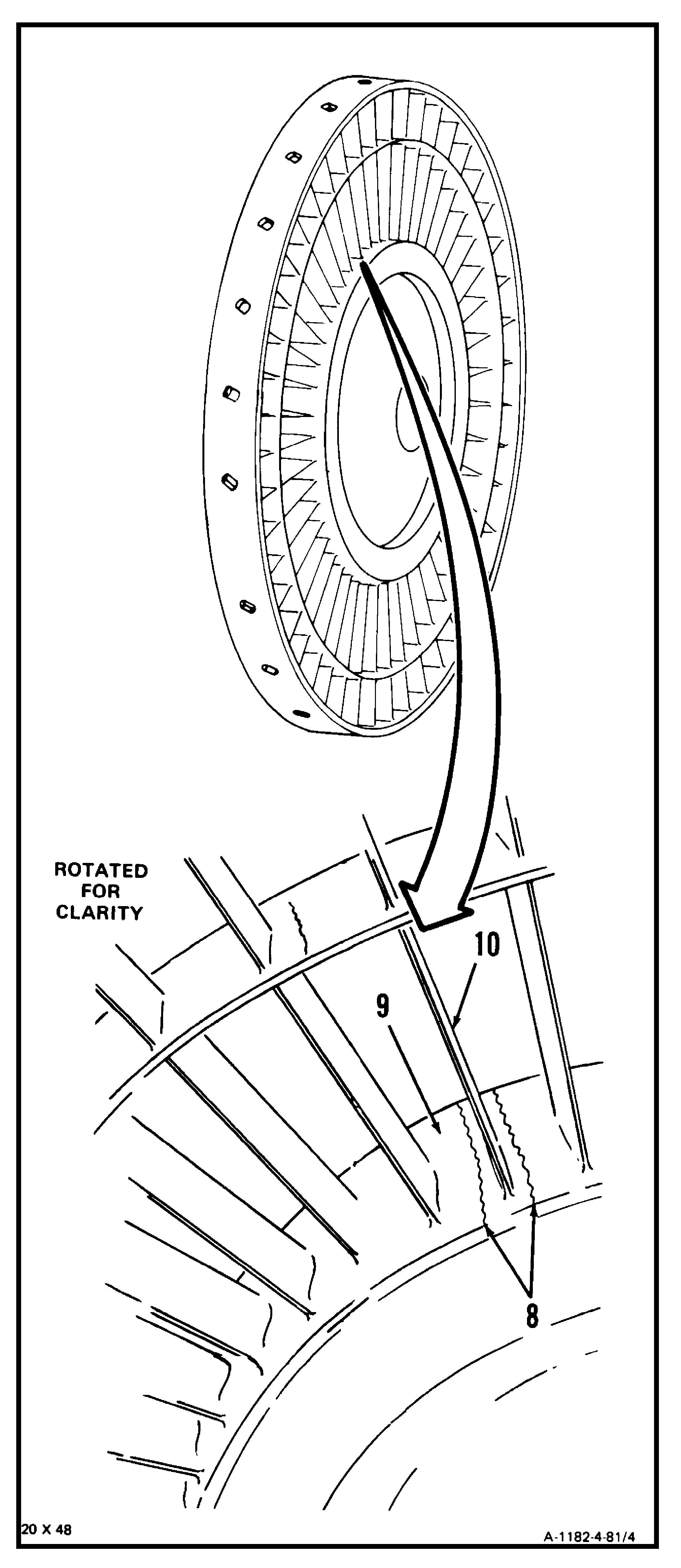

4–81 REPAIR EXIT VANE ASSEMBLY (Continued)

4–81

NOTE

In following step 3., use proper welding

procedure at all times (Ref. TM

1–1500–204–23–8).

3.

Using tungsten inert gas method, weld–re-

pair all cracks (6) in midspan shroud (7) if

any cracks in midspan shroud (7) exceeds in-

spection limits (Ref. Task 4–80).

WARNING

Power grinding is hazardous to per-

sonnel. Sparks and metal chips may

injure eyes. If injury occurs, get

medical attention.

a.

Wear goggles and rout cracks (6) to expose

clean, sound base metal. Use portable

electric drill and carbide burr.

b.

Clean chips, dirt, and oil from area to be

welded (Ref. Task 4–79).

NOTE

All welds in air flow path must be

blended smooth.

c.

Weld–repair. Use welding wire (E61). Do

not weld beyond inner shroud aft radius (5).

d.

Blend excess weld–repair with surrounding

parent metal. Use carborundum stone

(E10).

e.

Polish repaired area. Use crocus cloth

(E15).

f.

Fluorescent–penetrant inspect (per para-

graph 2–12.1.e) weld–repair area (Ref. TM

1–1500–335–23). There shall be no cracks.

If cracks are found, repeat steps a. through

e.

GO TO NEXT PAGE