TM 55-4920-328-13

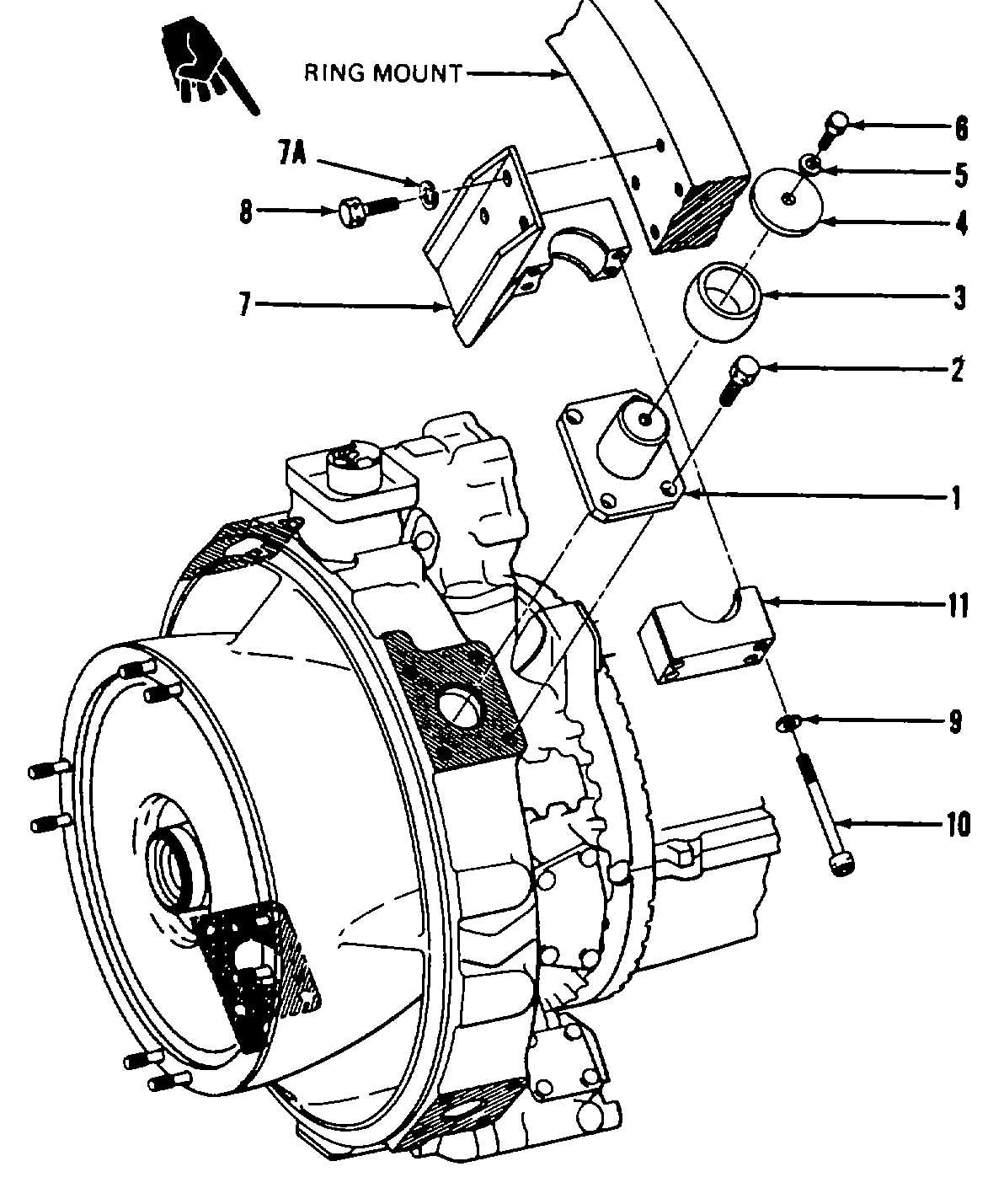

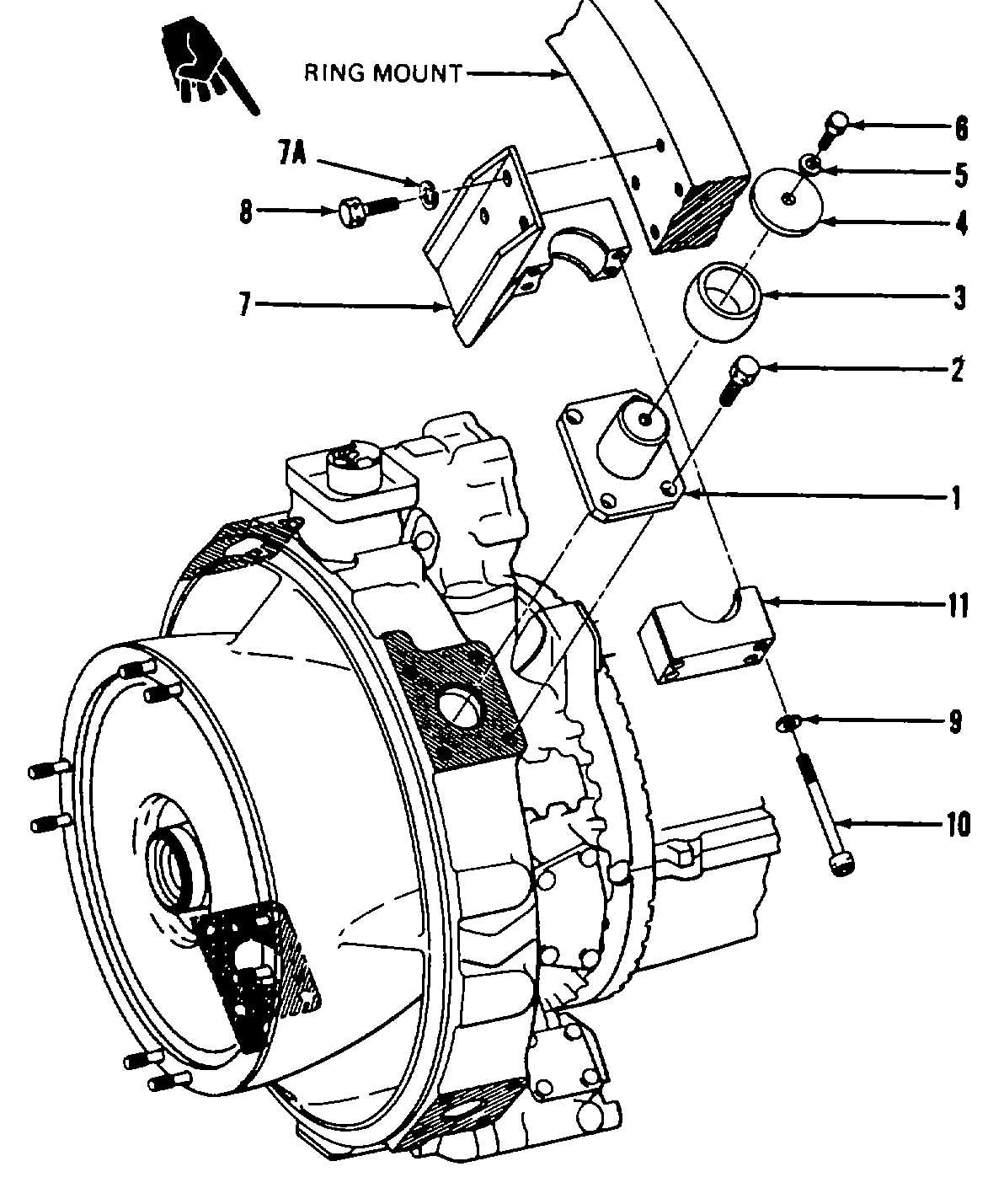

Figure 2-23. T55 Turboshaft Engine Mount Installation.

(5) Install hydraulic starter (7) and gasket (6) on

engine starter mounting pad.

NOTE

U.S. Army (USATSARCOM) author-

ized ECP No. MEG-01, dated March

26, 1981, identifies the replacing of

the gasoline engine driven hydraulic

starting unit and the battery starting

system with a Christie Rectifier

Power

Supply

starting

system.

(Army supported electrically drive

units are currently available.)

(5.1) On T55-L-712 model engines, if electric

starter is to be used in place of hydraulic starter, install

electric starter (3, figure 2-24.1) on engine starter

mounting pad.

(6) Apply molybdenum disulphide conforming to

Specification MIL-M-7866 to NI and NII tachometer

generator drive gears.

(7) Install NI tachometer generator (6), figure 2-25)

and gasket (7) on oil pump pad and secure with washers

(6B) and nuts (6A). Tighten nuts to 78 2 inch-pounds

torque.

(8) Install NIIl tachometer generator (5), gasket (4),

drive assembly (3), and packing (2) on accessory drive

gearbox and secure with washers (5B) and nuts (5A).

Tighten nuts to 78 2 inch-pounds torque.

(9) Install vibration adapter assembly (1, figure 2-

26) and vibration pickup (2) on engine aft vibration

mounting pad.

(9.1) Install bracket (76) and vibration pickup (7) on

diffuser front flange..

(10) On T55-L-7/7C model engines, remove dust

cover and install exhaust cone (17) with V-band clamp

(19). Tighten clamp to 390 10 inch-pounds torque.

Install dust cover on exhaust cone.

Change 4

2-104

1.

Engine Mount- TE6422

2.

Bolt - MS9505-11

3.

Ball - TE26838

4.

Washer - LTCT21865-01

5.

Washer - MS35338-44

6.

Bolt - MS9501-10

7.

Bracket - TE6418-02

7A.

Washer - MS35338-48

8.

Bolt - MS9505-11

9.

Washer - AN960-816

10.

Screw - LYC491-13H48

11.

Bracket Clamp - TE6418-03