TM 55-4920-328-13

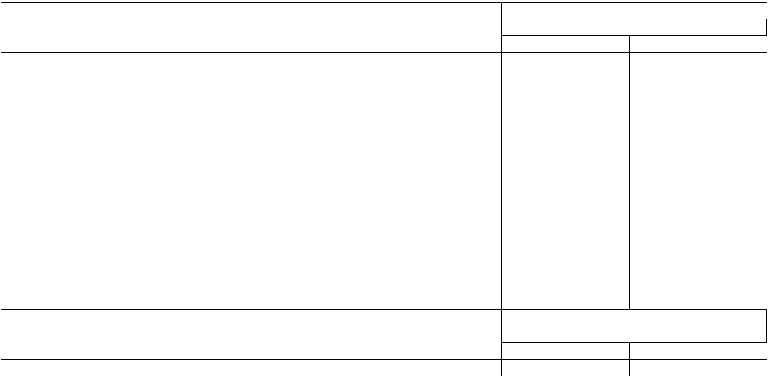

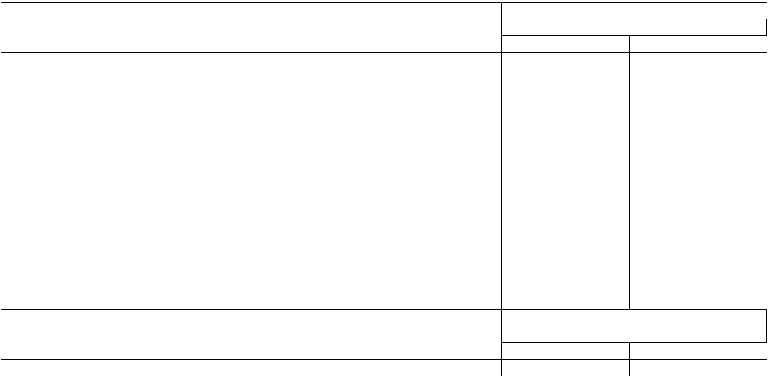

Table 5-2. Alarm System Verification by Shorting Pins

Data Acquisition Box

Alarm Card

(fig. FO-25)

Alarm Display on Unit 4A1

in Unit 4A2

Plug No.

Pins No.

Engine Chip Detector

J16

J7

S & Gnd

Engine Low Fuel Pressure

J19

J4

P & N

Engine Low Oil Pressure

J19

J4

L & M

Engine Low Oil Level

J18

J7

N & Gnd

Water Brake Low Oil Flow

J12

J7

AU & AV

Water Brake Low Oil Pressure

J12

J7

AU & AV

Water Brake Bearing H20 Flow

J11

J7

BH Common

BJ to BH

BK to BH

Test Trailer Power

Power Interconnect Box

Plug No.

Pins No.

Cooling Tower Low H20 Level

J11

J4

L & M

NOTE: The EGT overtemp alarms and the N1 and N2 overspeed alarms, must be setup by using signal simulation in

accordance with the calibration procedure, TB 55-4920-328-50.

NOTE

Tables 5-2 and 5-3 provide the

nomenclature of the alarm and pins

to be shorted for system verification.

c. Simultaneously depress the TIMER START

switchlight unit (35, figure 1-24) and start a stop watch.

d. After approximately one minute, simultaneously

depress the TIMER START switchlight unit (35) and

stop the stop watch. Verify that the elapsed time

indicator (37) and stop watch agree.

e. Depress and hold the TIMER RESET switchlight

unit (36) until the elapsed time indicator (37) resets to

000.0.

f. After checkout of the warning and timing circuits,

deenergize the electrical system as outlined in chapter

2.

5-17. Checkout and Adjustment of Oil Quantity

Electron Unit 2A10.

When the oil quantity system is suspected to be out of

tolerance, check and adjust the oil quantity electronic

unit (32, figure 1-23) as follows:

NOTE

The

following

procedures

are

applicable only when Specification

MIL-L-23699

lubricating

oil

is

contained in the test trailer oil

system.

5-8