TM 55-4920-328-13

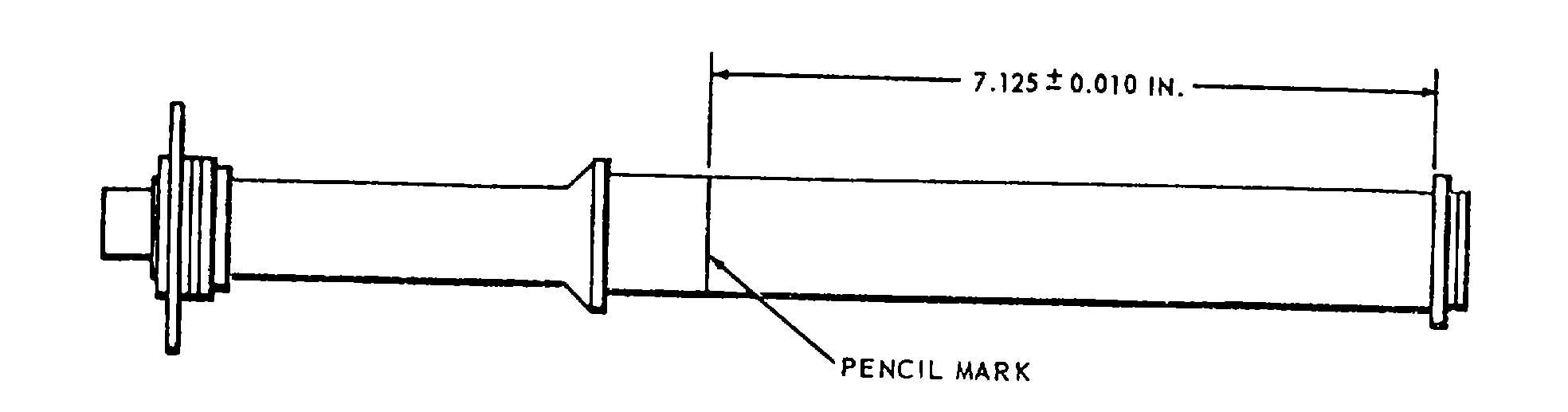

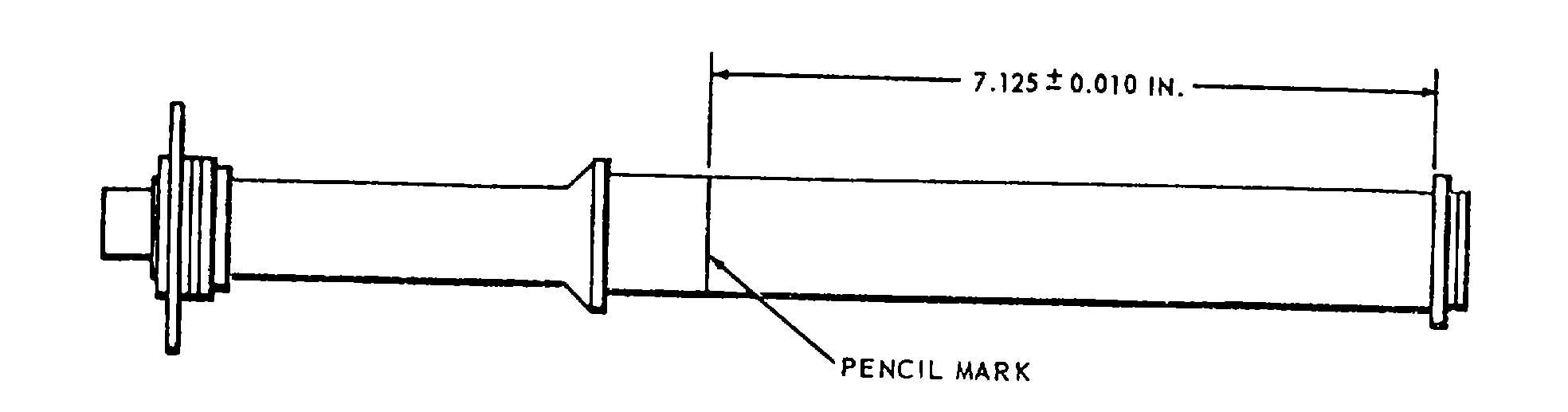

Figure 5-2. Marking Oil Quantity Probe

CAUTION

Do

not

adjust

the

ZERO

potentiometer at any time. This

adjustment

Is

accomplished

at

manufacture of the unit and is not to

be adjusted at any subsequent time.

Failure to observe this precaution

will result In erroneous readings

displayed

on

the

OIL/FLOW

CONSUMPTION monitor unit.

m. Loosen the locknut on the OIL PROBE DRY

potentiometer (34) and adjust the potentiometer for a

reading of 67.5 + 0.1 LBS on the OIL/FLOW

CONSUMPTION monitor. Tighten the locknut.

n. Using the same lubrication oil as in the system, at

the same temperature as the system, fill the beaker to

the pencil mark on the oil quantity probe.

o. Loosen the locknut on the OIL PROBE FULL

potentiometer (33) and adjust the potentiometer for a

reading of 147.7 + 0.5 LBS on the OIL/FLOW

CONSUMPTION monitor. Tighten the locknut.

p. Repeat steps (m) through (o) as required to

compensate for interaction of adjustments.

q. Remove the oil quantity probe from the beaker,

empty the oil from the beaker, and reinstall the probe in

the lubricating oil unit (6, figure 1-12).

5-18. Checkout of Mechanical Systems.

Checkout

of

METS

mechanical

systems

is

accomplished on a daily basis or prior to use; individual

component checkout is not required. Refer to chapter 2,

Preliminary Checkout Prior to Test paragraph for

information on checkout of mechanical systems.

5-10