TM 55-4920-328-13

6-61. Lube Water Filter System Maintenance.

NOTE

Install new filters every 50 hours

of engine test operation. Lube

water filter system has an alarm

that comes on when water flow

decreases to 8 gpm. When the

engine has been shut down due

to an alarm, both the METS water

system and the filter system must

be

checked

for

faults

and

corrected as necessary.

Normal water pressure is 65 to 100 psig. Clean

filters every 5 hours of operation or when filter pressure

decreases below 65 psig. Remove, clean, and replace

filter as follows:

a.

Loosen and remove ten wingnuts from filter

assembly cover. Remove cover (see figure 7-54).

b.

Remove 21 filter elements.

c.

Rinse filter elements in clear water and air-dry

them.

d.

Install 21 filter elements.

e.

Install cover. Install and tighten the ten

wingnuts. If cover leaks during engine operation,

retighten wingnuts as necessary.

6-62. Torque Tube Mount Rabbet Maintenance.

If inspection of torque tube mount detects nicks,

scratches, or other damage to rabbet surfaces (14,

figure 256), hand-work as necessary for proper fit to

water brake torque element.

6-63. Electric Starter Maintenance.

After every 300 starts, inspect starter commutator

and brushes as follows:

a.

Remove brush cover and inspect commutator.

The surface must be clean (free from oil or grease),

evenly colored, and with no evidence of excessive

burning.

b.

Brush springs shall not be burned or distorted.

c.

Brush holder assembly shall be clean (free from

oil or grease), and connections secure with no cracked

or burned brush holders.

d.

Brushes shall not be chipped or cracked and

they must move freely in the brush holders.

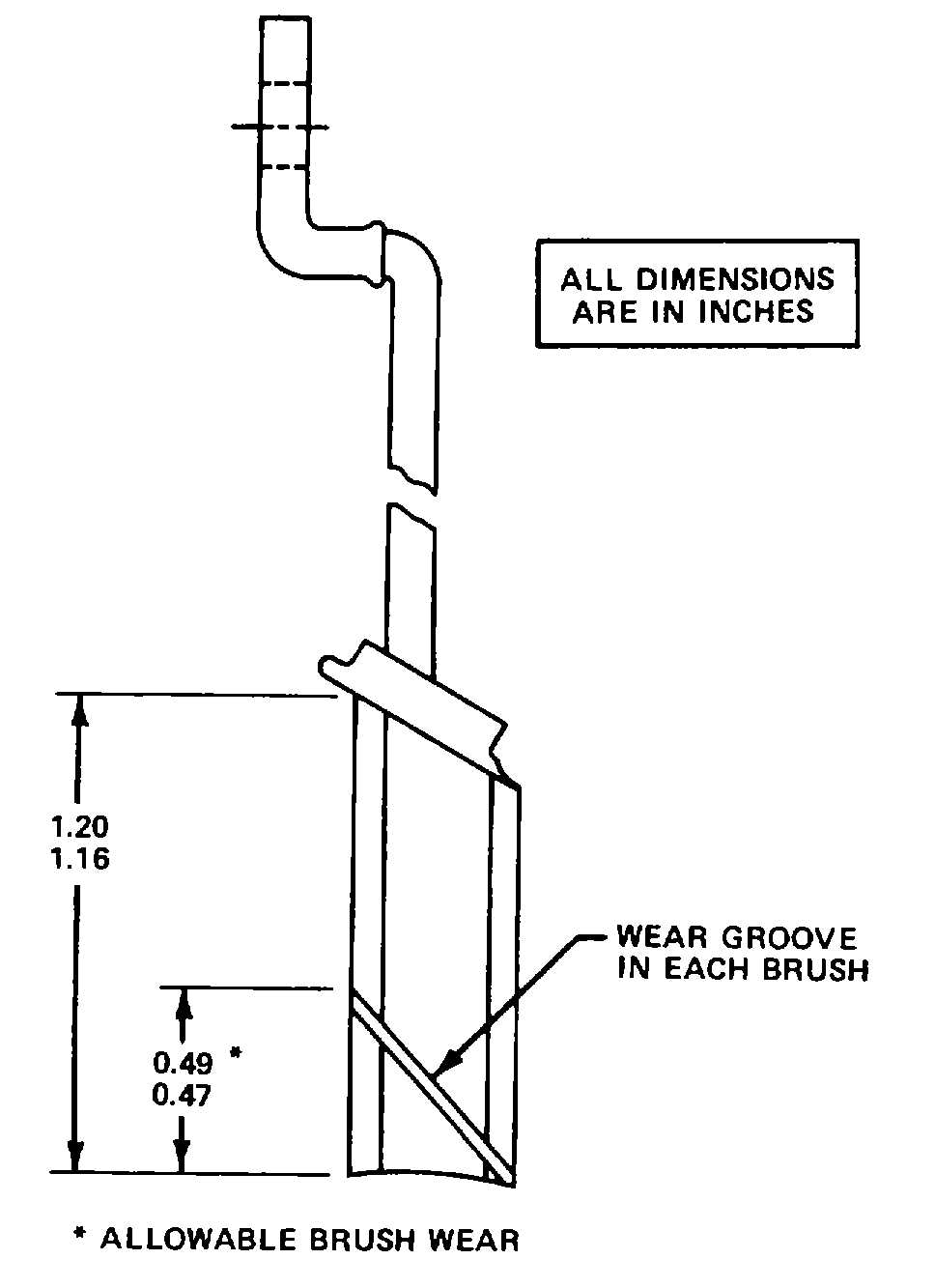

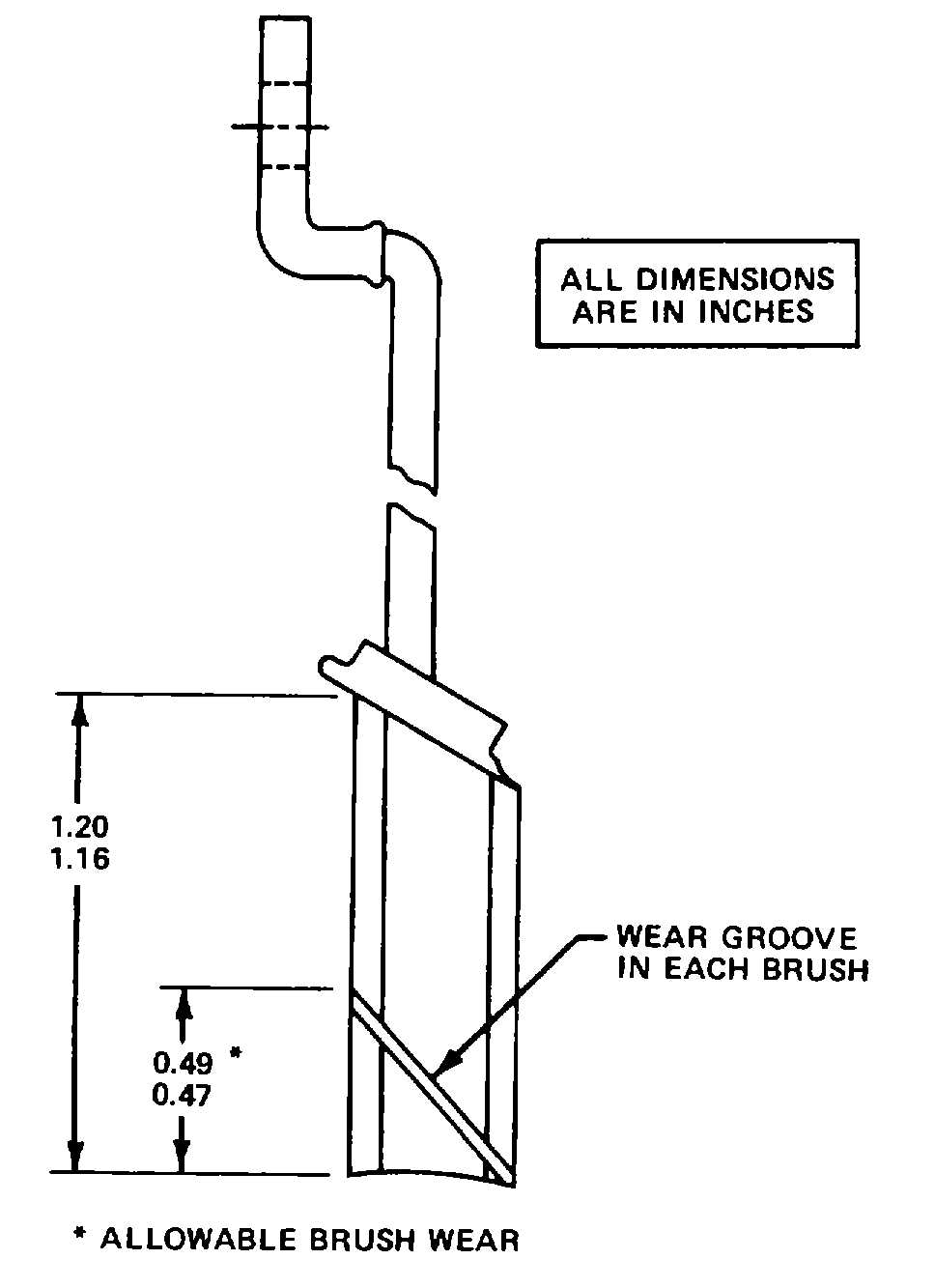

e.

Check that allowable brush wear will not be

exceeded before the next maintenance action. Refer to

figure 618 for allowable limits. If replacement is

indicated, return starter to depot for repair.

Figure 6-18. Starter Brush Wear Groove and

Allowable Wear.

Change 2 6-49/(6-50 blank)