TM 1-1500-204-23-1

11-21. Restraint Equipment. Restraint equipment, as

used in this section, includes safety lap belts, shoulder

harnesses, and other fabric devices used in Army

aircraft for personnel restraint purposes. Restraint

equipment is to be installed as directed in the applicable

maintenance manual. On all pilot/copilot and crewman

seat belts, the safety belt release handle should point to

the left.

NOTE

Seat belts will not be replaced for

cosmetic reasons.

a.

Inspection. All personnel restraint equipment is

to be visually inspected at time of installation and at

specified intervals thereafter. Inspections are explained

in the following paragraphs.

·

New Restraint Equipment. Perform

daily inspection for new seat belt

latches (MS3488(AS)) also Inspect for

fingertip access.

·

New Assemblies of Restraint

Equipment This equipment requires

no inspection during depot storage.

·

Seat

belt

latch

(MS3488(AS)).

Inspect

for

fingertip

clearance.

Inspect each seat belt latch by using a

steel scale to measure the clearance

distance between the inside face of

the top of the grip and the top of the

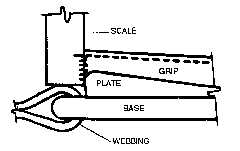

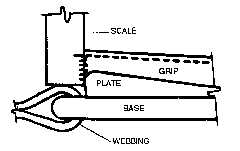

webbing, as shown In figure 11-6.

WARNING

Except for leg garters used with the

MK-5D ejection seat, all restraint

assemblies made of cotton webbing

shall be removed from service. Use

extreme caution when inspecting

restraint equipment on ejection seat

equipped

aircraft.

Ensure

appropriate safety pins are installed.

Injury to personnel may otherwise

result.

Figure 11-6. Measuring Fingertip Clearance

(1)

Installation inspection. Visually inspect all

restraint equipment prior to installation. Seat belt

latches shall be inspected for fingertip clearance in

accordance with the following procedures.

(a) Inspect each seat belt latch by using a

steel scale to measure the clearance distance between

the inside face of the top of the grip and the top of the

wedding, as shown in figure 11-6

(b) If the distance measured above is less

than the thickness of gloved fingers (minimum 0.8 inch)

alter latch using the following procedures:

1

Open latch so that sides may be

placed in vise equipped with aluminum or brass

protective plates on jaws.

2

Squeeze sides of latch handle

together using constant, even vise pressure until jaws

are approximately 1 3/4 inches apart. Latch will deform

upward and inward, as shown in figure 11-12.

3

Repeat as necessary to obtain

7/8-inch clearance dimension due to spring back of

metal.

4

Perform

visual

inspection

for

cracks.

5

Check operation of latch and

detent for complete lock and release.

11-20