TM 1-1500-204-23-2

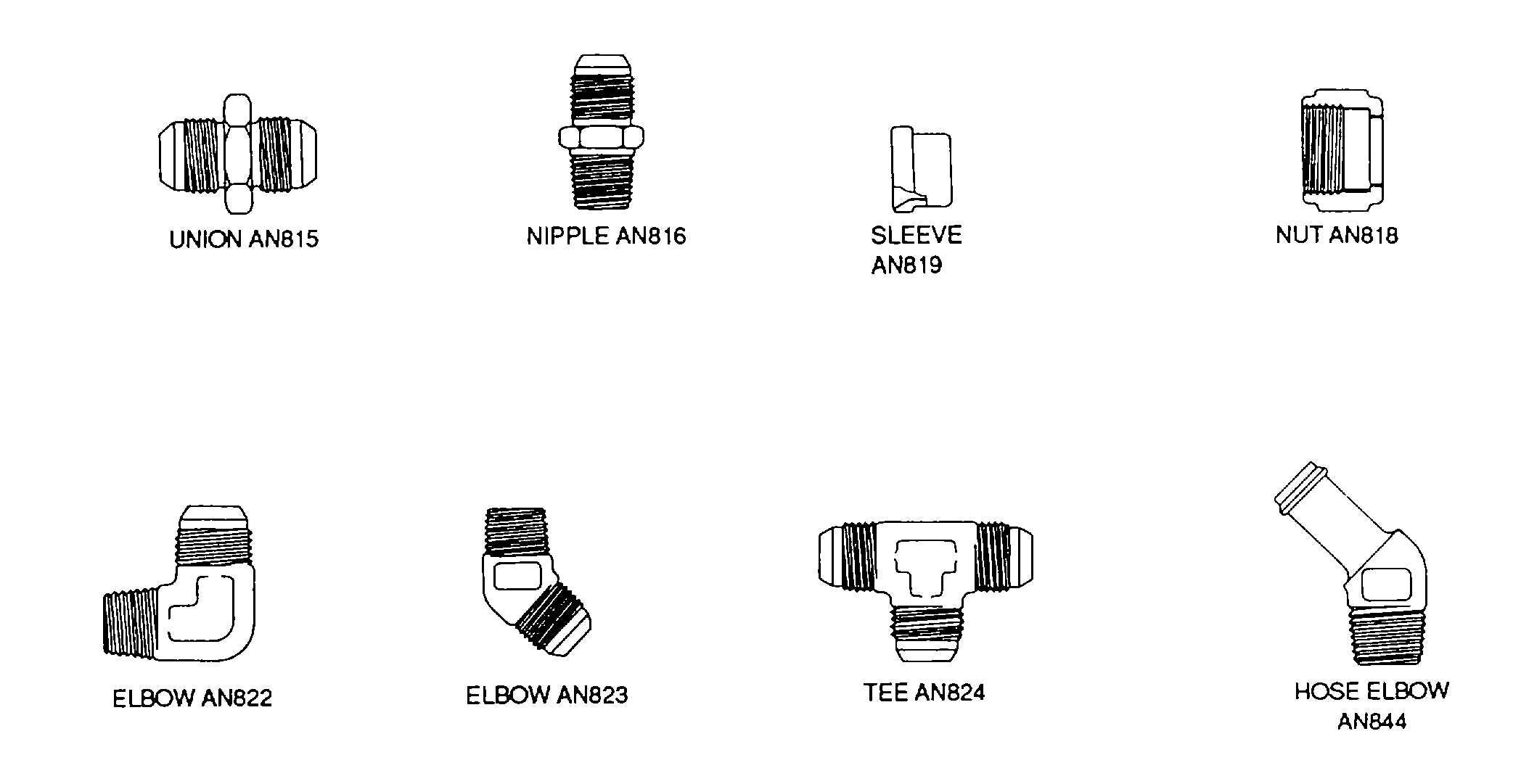

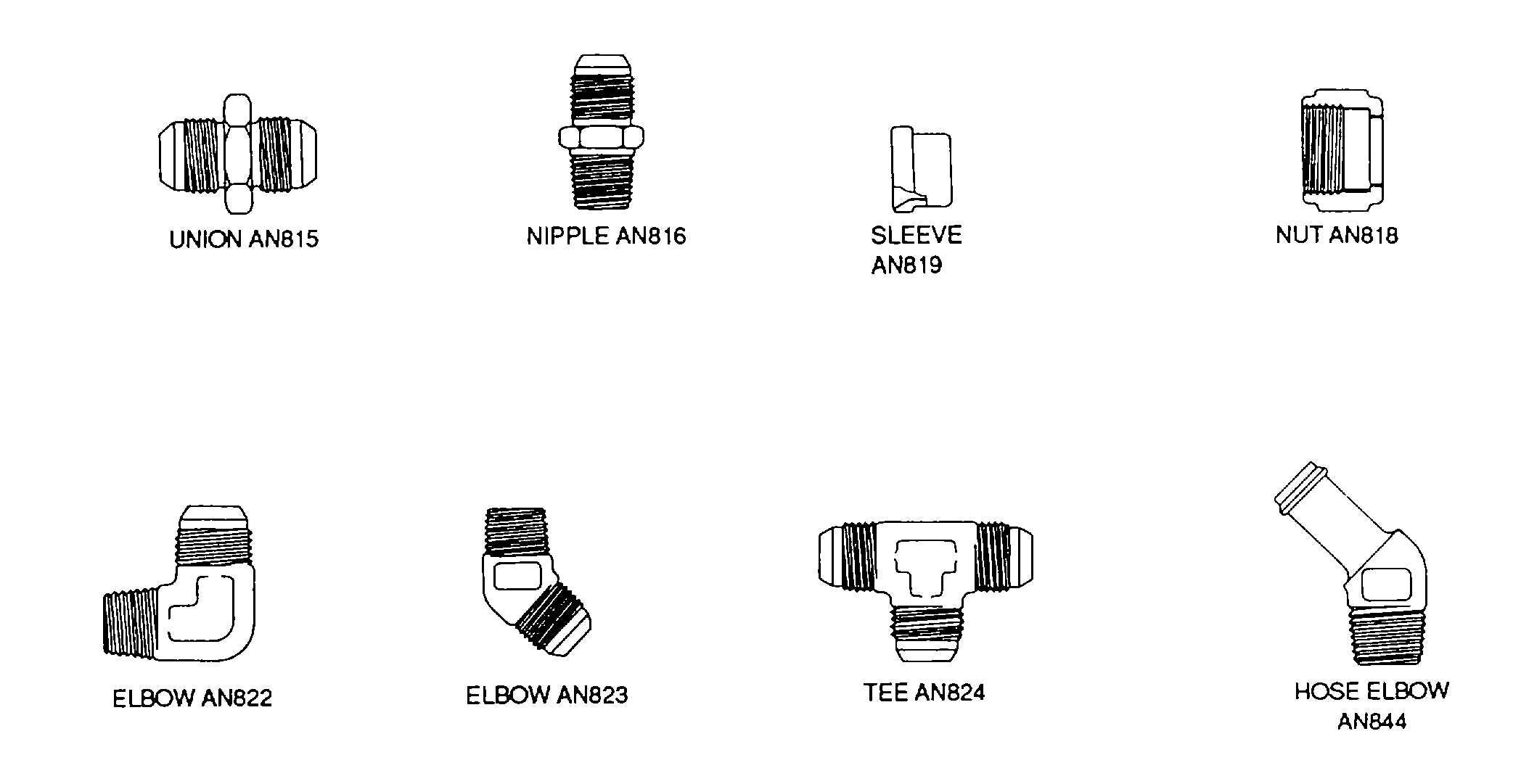

Figure 4-28. AN Flared Fittings

(5) Position repair insert

NOTE

When positioning hose clamps or tightening

screws, care should be taken to prevent

screws from chafing or damaging adjacent

parts. Where such damage is possible, hose

clamps should be repositioned on hose.

(6) Slip hose connections midway over junction

formed by original tube and repair section Use

glycerine, Federal Specification O-G-491, on metal pipe

to aid sliding of rubber hose.

(7) Tighten hose clamps. To prevent breakage

of hose clamps and damage to hose, instructions on

tightening hose clamps shall be followed carefully

When available, use any approved torque wrench to

torque clamps as per (a) OR (b) below, depending on

the hose type. In the absense of a hose clamp torque

wrench, the fingertight-plus-turnsmethod shown In table

4-10 should be used. Due to the variance In hose clamp

design and hose structure, values given in table 4-10

are approximate and care should be exercised when

tightening clamps by this method.

NOTE

Aircraft hose constructed with synthetic com-

pound has a tendency to cold flow, therefore,

when new hose is Installed, clamps should,

after a period of time, be retightened In order

to maintain original torque value. This is

caused by synthetic rubber flowing from

under clamping area and not from loosening

of clamps.

(a) Hose clamps installed on self-sealing

hose shall be tightened to a torque of 25 Inch-pounds

minimum to 30 Inch-pounds maximum for original Instal-

lation, and maintained at this torque value When seal-

ing is not effective at 30 Inch-pounds, component parts

of connection shall be examined, and unserviceable

parts replaced Under no circumstances shall hose

clamp be tightened In excess of 30 Inch-pounds In an

attempt to effect sealing This added torque will reduce

safety factor of hose clamp as well as destroy hose and

connection.

(b) Hose clamps Installed on nonself-sealing

hose shall be Installed and maintained at a torque of 25

inch-pounds minimum to 30 Inch-pounds maximum. If

satisfactory sealing is not accomplished at a torque of

4-27