TM 1-1500-204-23-2

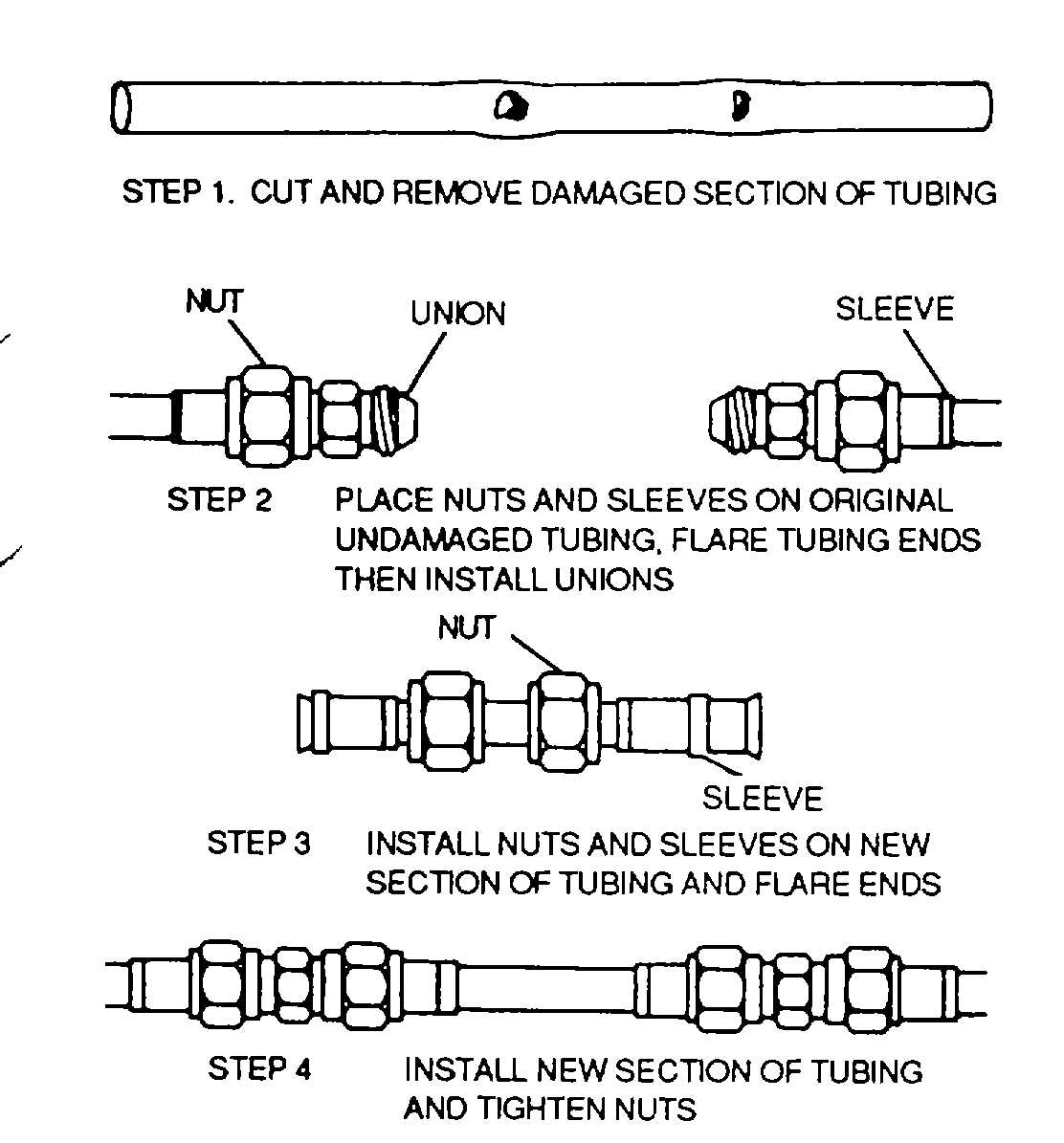

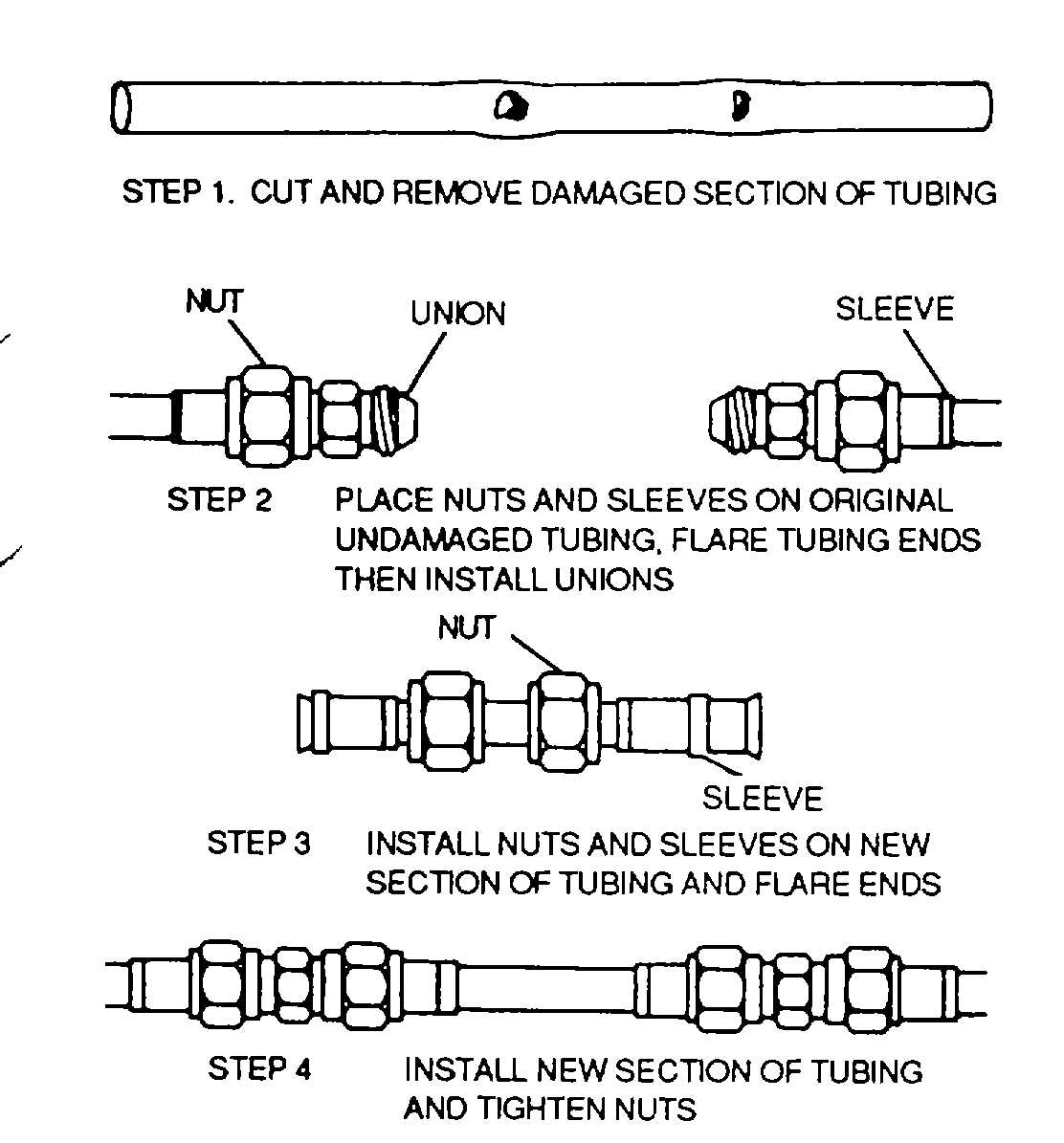

Figure 4-33. Repairing High-Pressure Tubing

be made of aluminum alloy conforming to Federal

Specification WW-T-700/4.

NOTE

Copper tubing of same outside diameter and

wall thickness may be used in oxygen sys-

tems only In case of emergency, and should

conform to Federal Specification WW-T-799,

Type N. Steel tubing shall not be used be-

cause it loses its ductility and becomes brittle

at low temperature.

(a) Tubing material. When replacing a

damaged tubing assembly, the same size and material

shall be selected. Where like materials are not available,

wall thickness which can be used for various diameters

and tubing materials under applicable system pressure

are shown in table 4-11. The following paragraphs

explain the use of this table.

1 Explanation of codes. The following

information applies to the code symbols The codes

shown in table 4-11 indicate that these sizes are stand-

ard.

TUBING

CODE

MATERIAIL

SPECIFICATION

a

Aluminum

5052-0

FED SPEC WW-T-700/4

b

Aluminum

2024T

FED SPEC WW-T-700/3

c

Corrosion-

Resistant Steel

Annealed

MIL-T-8504

d

Corrosion-

Resistant Steel

1/4 hard

MIL-T-6845

2 Minimum burst pressures. In accord-

ance with MIL-H-5440, the following minimum tube

burst pressures are required for the noted system pro-

cedures:

SYSTEM PRESSURE

BURST PRESSURE

1,000

4,000

1,500

6,000

3,000

12,000

3 Conversion factors Following are the

conversion factors for the materials in table 4-1 1 and the

three system pressures.

MATERIAL SYSTEM

CONVERSION

CODE

PRESSURE (PSI)

FACTOR

a

1,000

1,380

1,500

2,070

3,000

4,140

b

1,000

625

1,500

938

3,000

1,875

c

1,000

533

1,500

800

3,000

1,600

d

1,000

333

1,500

500

3,000

1,000

4-31