TM 1-1500-204-23-2

Table 4-10. Hose Clamp Tightening, Fingertight-Plus Turns Method

Clamps, Radial

Instal Installation

Clamp, worm screw-type

and other type

only

(10 threads per Inch)

(28 threads per Inch)

Self-Sealing Hose

Fingertight Plus 2

Fingertight Plus 2 1/2

Complete Turns

Complete Turns

Approximately 25 to 30

Inch-Pounds

All Other Aircraft Hose

Fingertight Plus 1 1/2

Fingertight Plus 2

Approximately 25 to 30

Complete Turns

Complete Turns

Inch-Pounds

30 inch-pounds, component parts of connection shall be

examined and unserviceable parts replaced.

(c) Hose clamps installed on rubber nipple-

type fuel cell fittings and fuel system molded rubber

connections shall be tightened to a torque of 15 inch-

pounds for original installation, and maintained at finger-

tight plus 1 1/4 turns. Fuel cell fittings are very easily

damaged by hose clamps; therefore, these torque

values shall be followed.

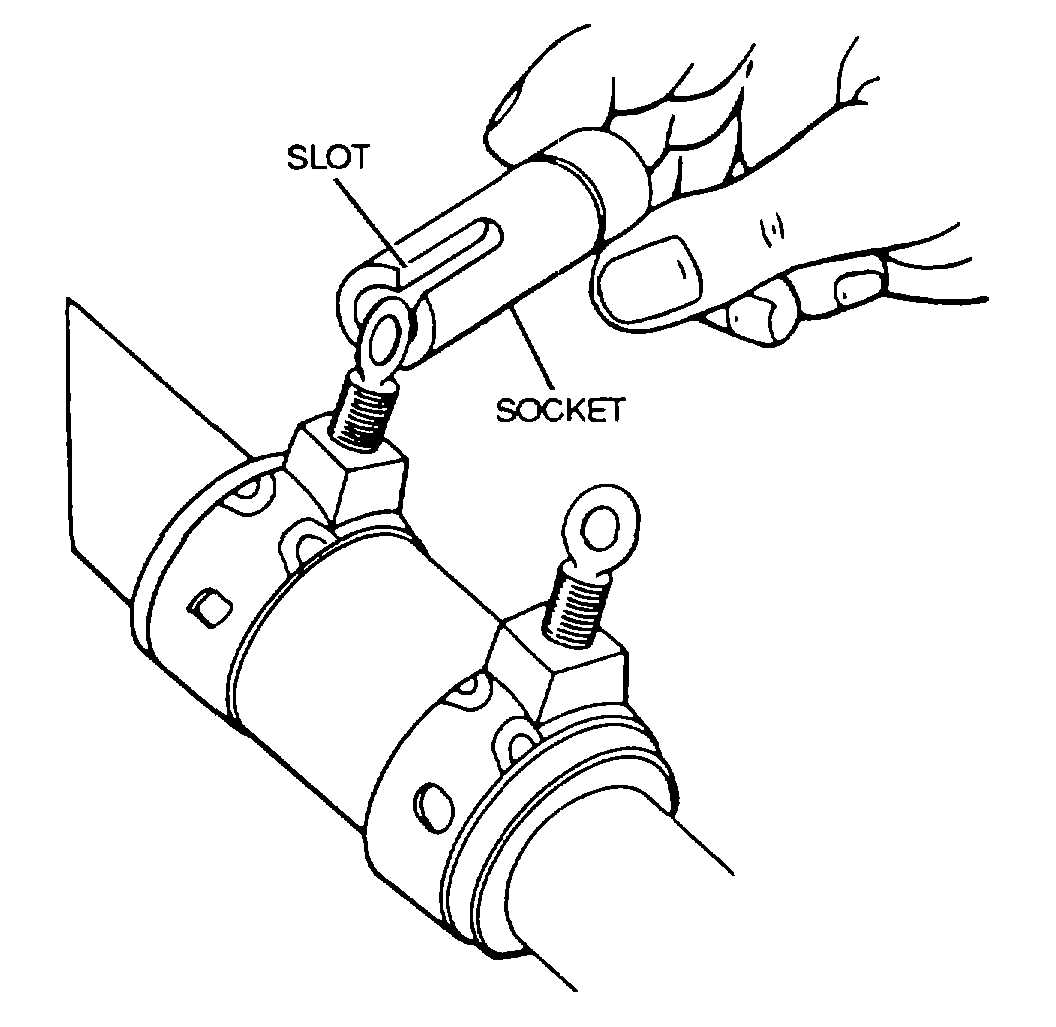

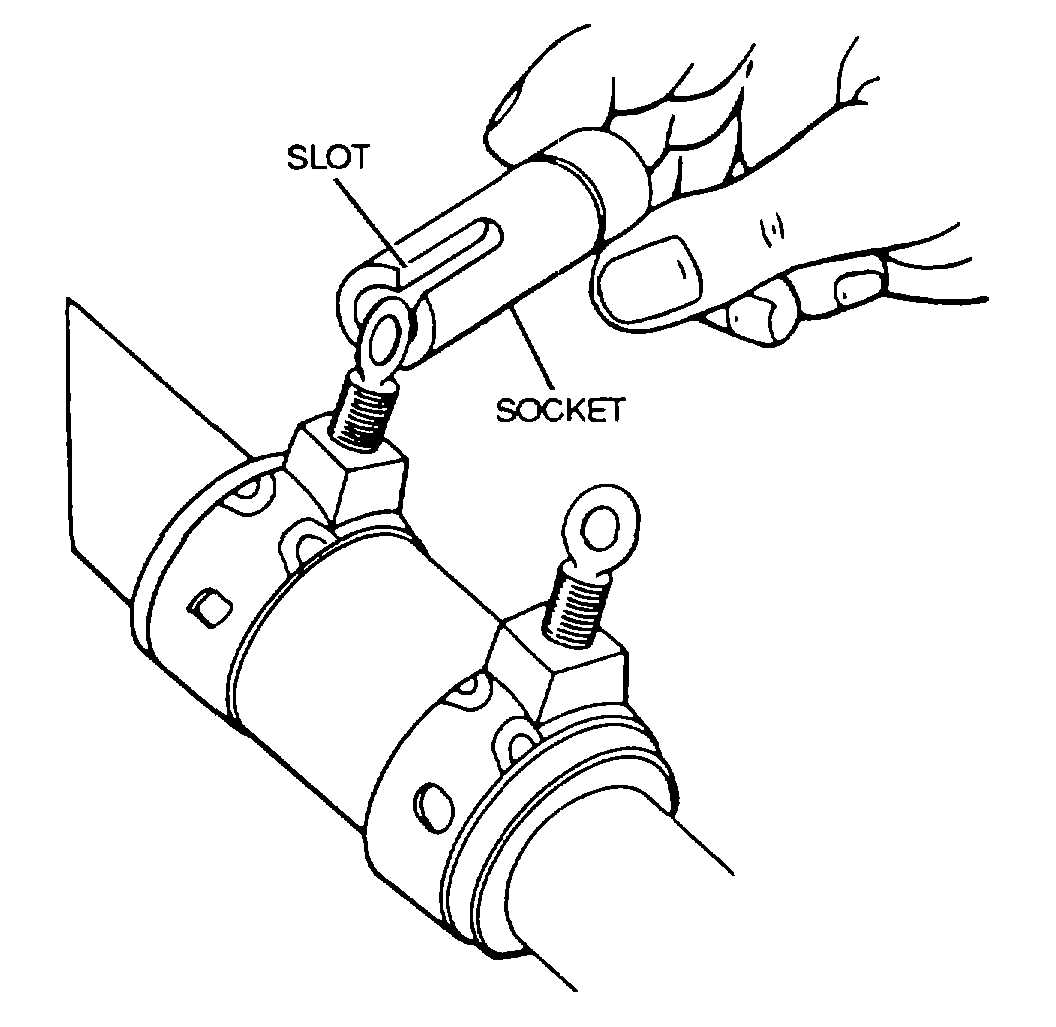

(d) As an alternate method, hose clamps may

be tightened with a special hose clamp tool easily

fabricated from a long midget socket (figure 4-32) A slot

is cut through hex end of socket wide enough and deep

enough to accommodate thumbscrew portion of hose

clamp. This type of tool may be used on the end of a

ratchet or extension.

c. Repair of High-Pressure Tubing Assemblies

High-pressure tubing assembly can be repaired either

by removal of the damaged section and a union in-

stalled, or by replacement of the entire tubing assembly.

(1) Repair. The damaged portion of tubing is

cut out and removed (see figure 4-33). The ends of the

remaining tubing are cleaned and deburred. If the

damaged section of the tubing does not exceed the

length of a union, a new tube section is not needed.

(2) Replacement. If a tubing assembly Is to be

replaced, fittings can usually be salvaged and replacing

assembly will amount to replacement of tubing only. If

tubing is small and made of soft material, assembly may

be formed during installation by hand bending. How-

ever, if tubing is of such material and size that hand

bending is impractical, care shall be taken to remove

assembly without further damage or distortion so that it

can be used as a forming template. This will allow

duplication as to length, bends, and angles. All tubing

for replacement in low pressure oxygen systems shall

Figure 4-32. Tightening Hose Clamp with Socket

4-30