TM 1-1500-204-23-3

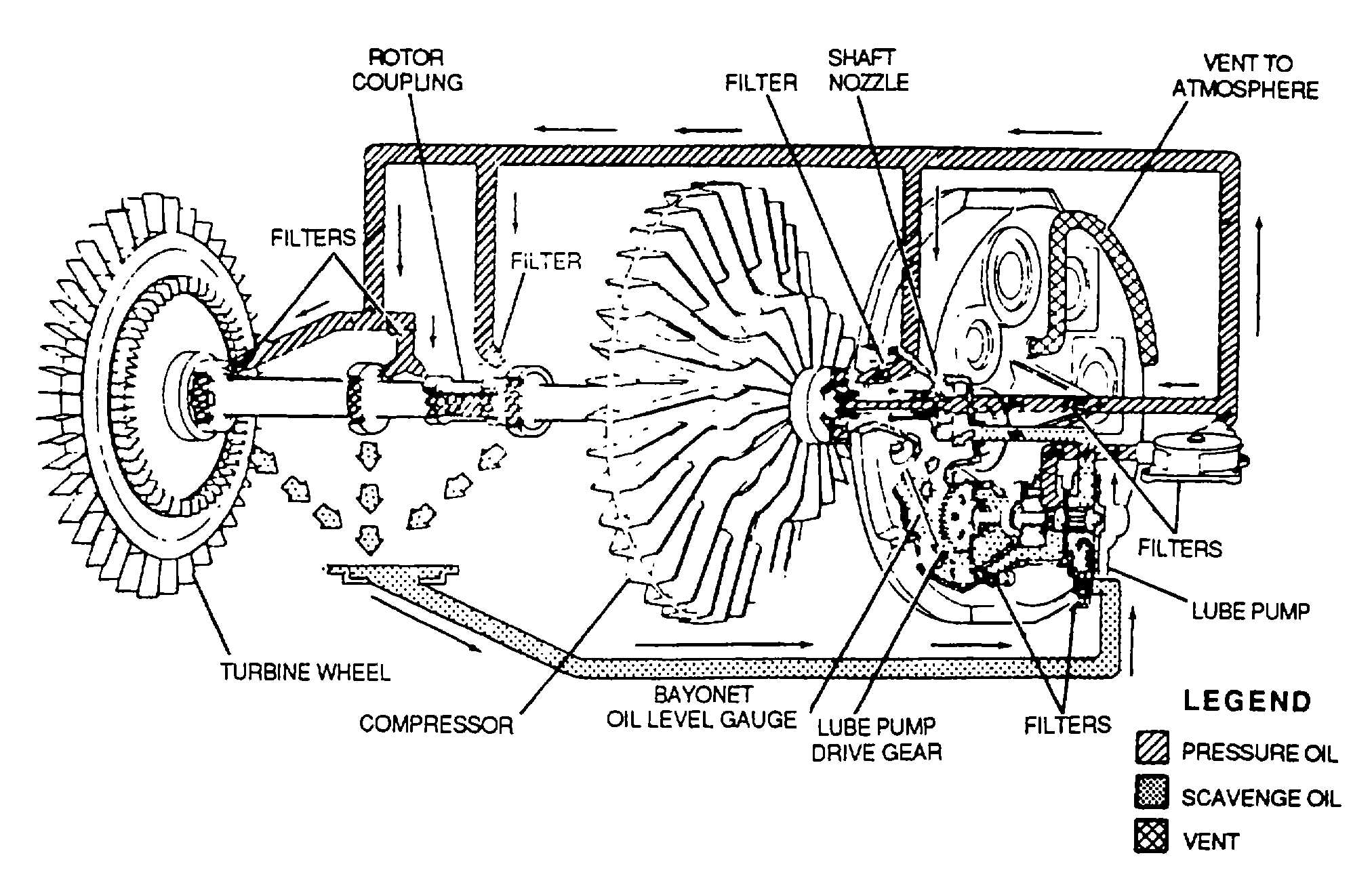

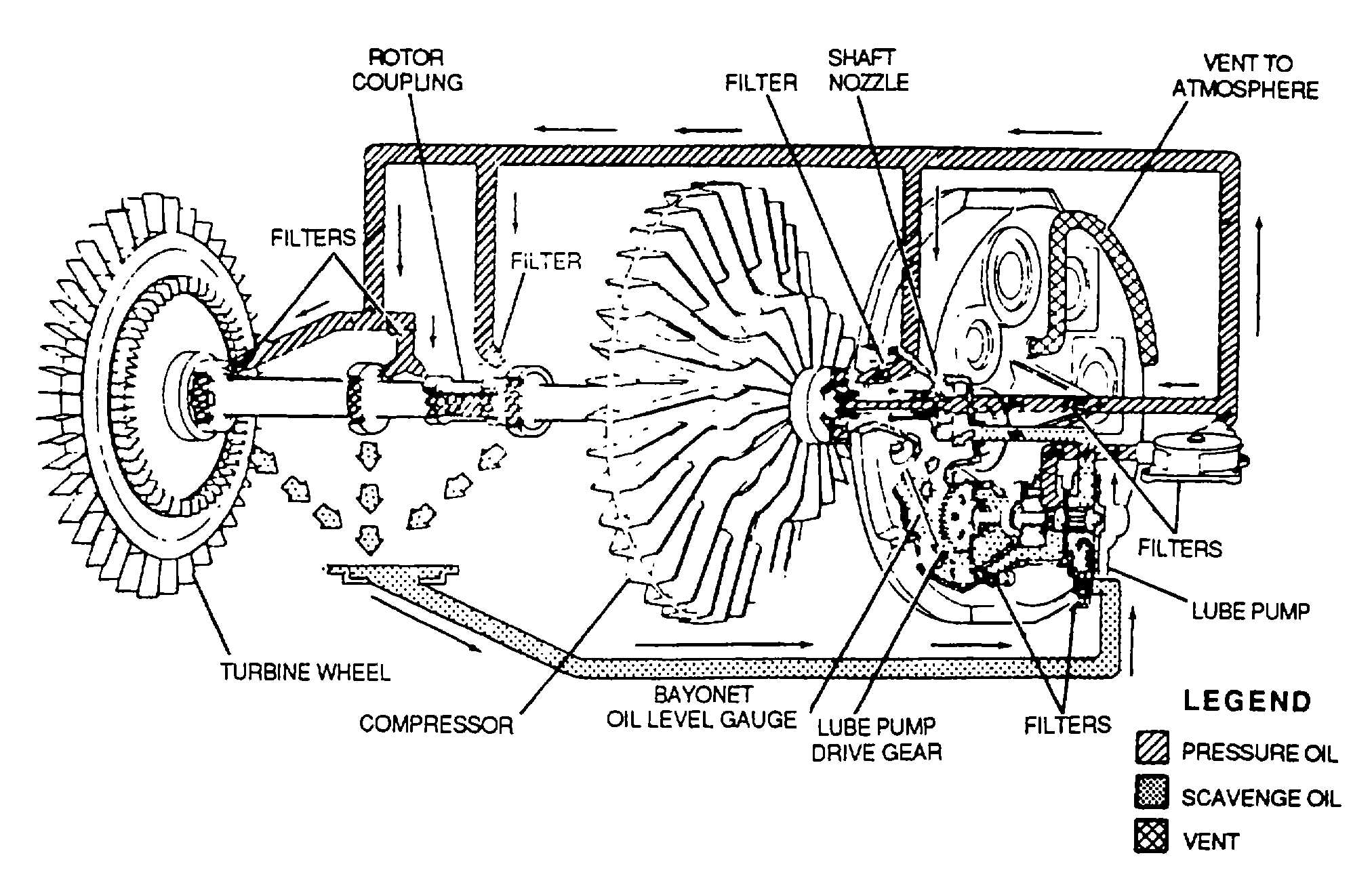

Figure 3-4. Wet-Sump Lubrication System for Turbine Engines

(b)

After removing tubing or hose, cap or plug ends to prevent entry of foreign material; also plug or cap

fitting from which tubing or hose was removed for the same reason.

(c)

Remove fittings from tubing, hose, or components with the correct size wrench to prevent

malforming the fittings.

WARNING

•

Drycleaning solvent is flammable and solvent vapors are toxic. Use P-D-680, Type II

Solvent in a well-ventilated area. Keep away from open flames. Avoid prolonged solvent

contact with skin.

•

When using air pressure, be extremely careful. Do not blow stream of air toward yourself

or any other person. Users of air pressure and personnel within the immediate area shall

wear safety glasses, goggles, or face shield. Ear protection may be required. Pressure

will not exceed 30 psig. Failure to comply may result in injury.

(2)

Cleaning. Clean removed tubing, hose, and fittings by blushing or submerging in drycleaning solvent P-D-

680, Type II, and dry with clean, dry, compressed air.

(3)

Inspection. Inspect tubes, hoses, and fittings as follows:

(a)

Inspect hose for chafing, fraying, and cuts, deterioration, cold flow, weather checking, and excessive

wire damage (braided wire covered).

(b)

Inspect tubing for chafing, cracks, and corrosion.

(c)

Inspect oil line fittings for malformed threads, cracks, and general condition.

(4)

Installation. During installation, rotate coupling nut of tubing or hose with one wrench while holding fitting

to which it is being secured with another wrench. This procedure prevents twisting of the tubing or hose. Oil lines shall

be secured with metal clamps having an oil-resistant cushion, in such a manner as to ensure 1/4 inch minimum

clearance between tubing and

3-7