TM 1-1500-204-23-3

WARNING

Drycleaning solvent is flammable

and solvent vapors are toxic. Use

P-D-680, Type II Solvent in a well-

ventilated area. Keep away from

open flames. Avoid prolonged

solvent contact with skin.

1

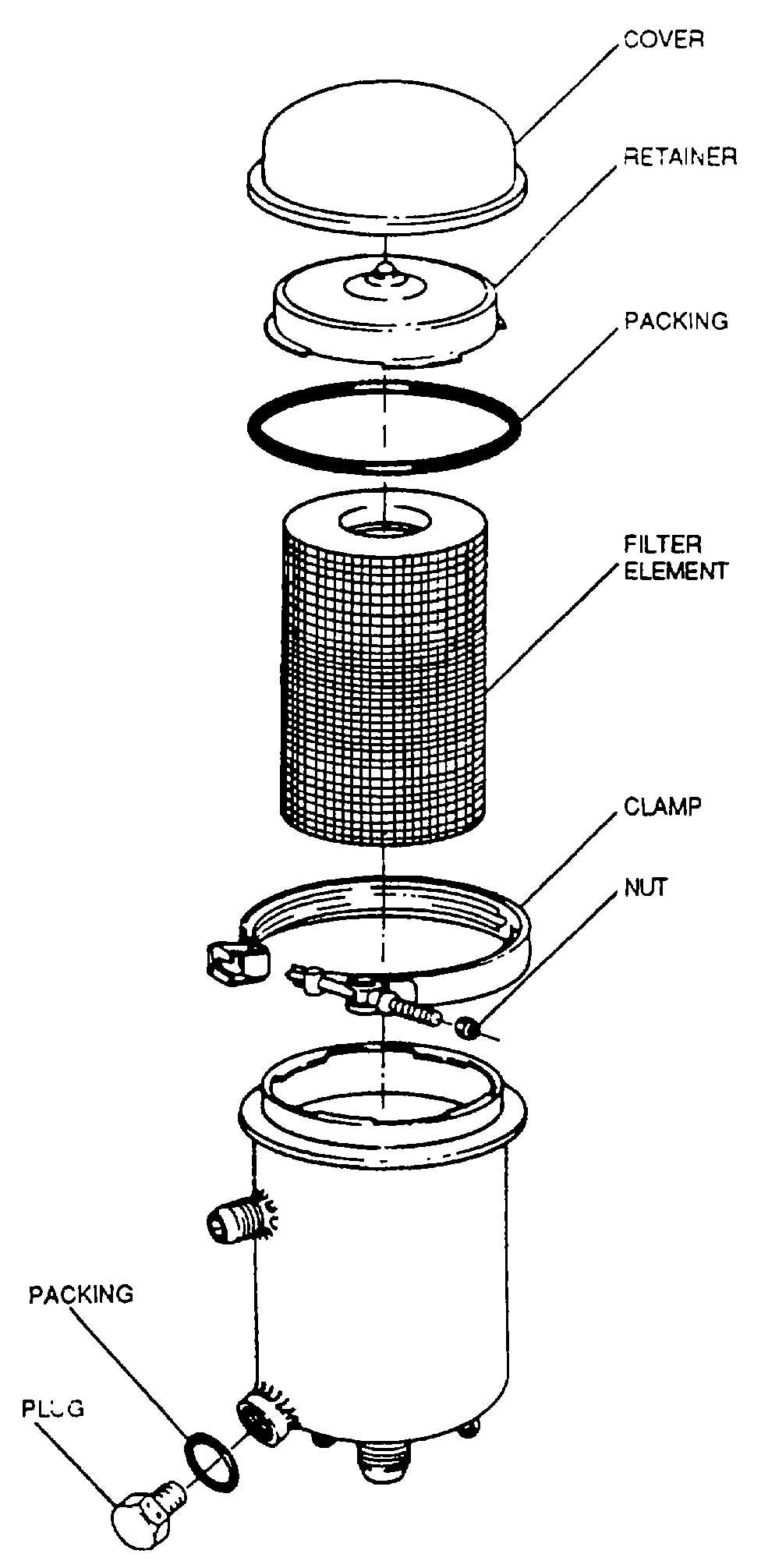

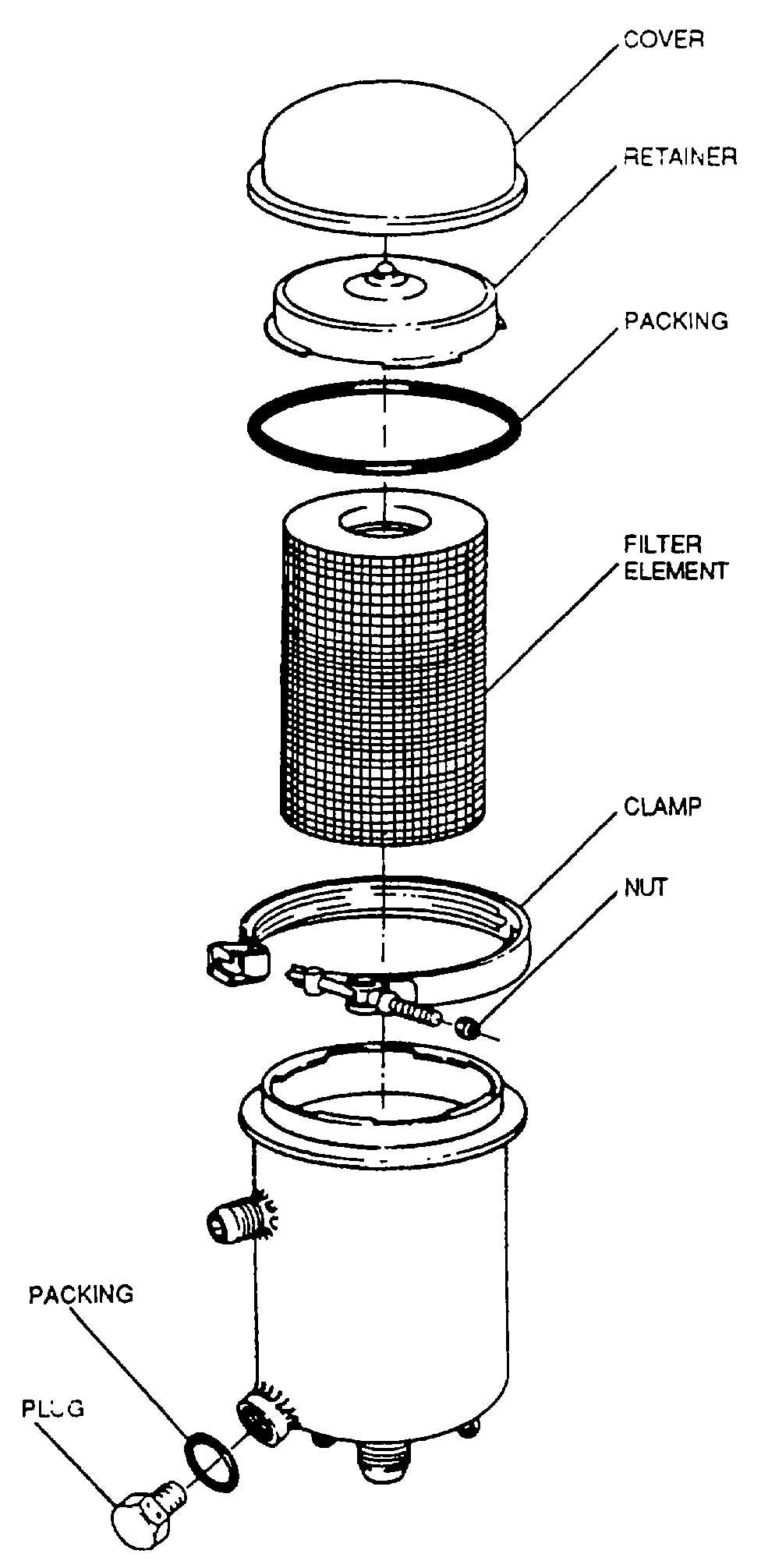

Screen-type. The screen-

type, as shown in figure 3-6, with its double-walled

construction, provides a large filtering area in a compact

unit. As oil passes through the fine-mesh screen, dirt,

sediment, and other foreign matter are removed and

settle to the bottom of the housing. At regular intervals,

the cover is removed and the screen and housing

cleaned with a drycleaning solvent, P-D-680, Type II.

2

Cuno-type. The Cuno oil

filter has a cartridge made of disks and spacers. A

cleaner blade fits between each pair of disks. The

cleaner blades are stationary, but the disks rotate when

the shaft is turned. Oil from the pump enters the

cartridge well that surrounds the cartridge and passes

through the spaces between the closely spaced disks of

the cartridge, then through the hollow center, and on to

the engine. Any foreign particles in the oil are deposited

on the outer surface of the cartridge. When the

cartridge is rotated, the cleaner blades comb the foreign

matter from the disks. The cartridge of the manually-

operated Cuno filter is turned by an external handle.

Automatic Cuno filters have a hydraulic motor build into

the filter head. This motor, operated by engine oil

pressure, rotates the cartridge whenever the engine is

running. There is a manual turning nut on the automatic

Cuno filter for rotating the cartridge manually during

inspections.

3

Air-maze-type. The Air-

maze filter contains a series of round, fine-meshed

screens mounted on a hollow shaft. The oil from the

pump enters the well, surrounds the screens, and then

passes through them and the shaft before entering the

engine. The carbon deposits that collect on the screens

actually improve their filtering efficiency.

(b)

Turbine engines. Filters are an

important part of the lubrication system, since they

remove foreign particles that may be in the oil. This is

particularly important in gas turbines, as very high

engine speeds are attained, and the antifriction types of

ball and roller bearings would become damaged quite

rapidly if lubricated with contaminated oil. Also, there

are usually a number of drilled or core passages leading

to various points of lubrication Since these passages are

usually rather small, they are easily clogged. The

spacers and screens and main oil strainer are explained

in the following paragraphs.

1

Spacers

and

screens.

This filter, as shown in figure 3-7, is made up of a stack

of metal disks covered with a screen and separated by

spacers so that the oil can flow through the screens and

out the outlet port of the strainer body.

Figure 3-6. Oil Filter

3-9