TM 1-1500-204-23-4

(d) Contact safety specialist and

medical

personnel

to

determine

the

extent

of

contamination and corrective procedures to follow. A

mercury vapor detector will be used to monitor the air in

areas where mercury contamination is suspected.

Operations will not be resumed until the concentration of

mercury vapor drops below 0.05 milligram per cubic

meter.

(e)

Recover

visible

droplets

of

mercury with a mercury vacuum cleaner, mercury

scoop, or a suction device equipped with a water trap.

The contaminated areas should then be coated with a

mercury suppressant, such as one percent calcium

polysulphide, flours of sulfur, or equivalent; then

carefully sweep and pick up contaminated suppressant

materials, and wet-mop the area. The decontaminants

do not remove mercury but coat the droplets and thus

reduce volatilization of the mercury. Monitoring of the

area with a mercury vapor detector should be performed

to determine the thoroughness of the decontamination

procedures.

(f)

Air-conditioning

systems

of

Sheffield

Modulabs

will

be

deactivated

until

contaminated areas have been decontaminated. Area

will be monitored with a mercury vapor detector to

determine thoroughness of decontamination.

(7) Maintenance. To ensure that the

manometer is ready for operation at all times, it must be

inspected systematically before, during, and after

operation. Defects should be discovered and corrected

before they result in serious damage or failure. Defects

or unsatisfactory operating characteristics beyond the

scope of the operator to correct must be reported at the

earliest opportunity to organizational maintenance.

Responsibility

for

performance

of

preventive

maintenance services rests not only with the operator,

but with the entire chain of command from section chief

to commanding officer.

b. Vacuum Chambers. Vacuum chamber

maintenance procedures are covered in the following

paragraphs.

(1) Inspection. Inspect door seal for defects

or damage. When seal is damaged to the extent that it

will not seal properly, it shall be replaced. A thin coat

glycerol, Federal Specification O-G-491, may provide a

temporary seal when defects are slight.

WARNING

Drycleaning solvent is flammable

and solvent vapors are toxic. Use

P-D-680, Type 11 Solvent in a

well-ventilated area. Keep away

from

open

flames.

Avoid

prolonged solvent contact with

skin.

(2) Cleaning. Periodically clean vacuum

chamber with a cloth dampened in drycleaning solvent,

Federal Specification P-D-680, and wipe dry with a

clean cloth.

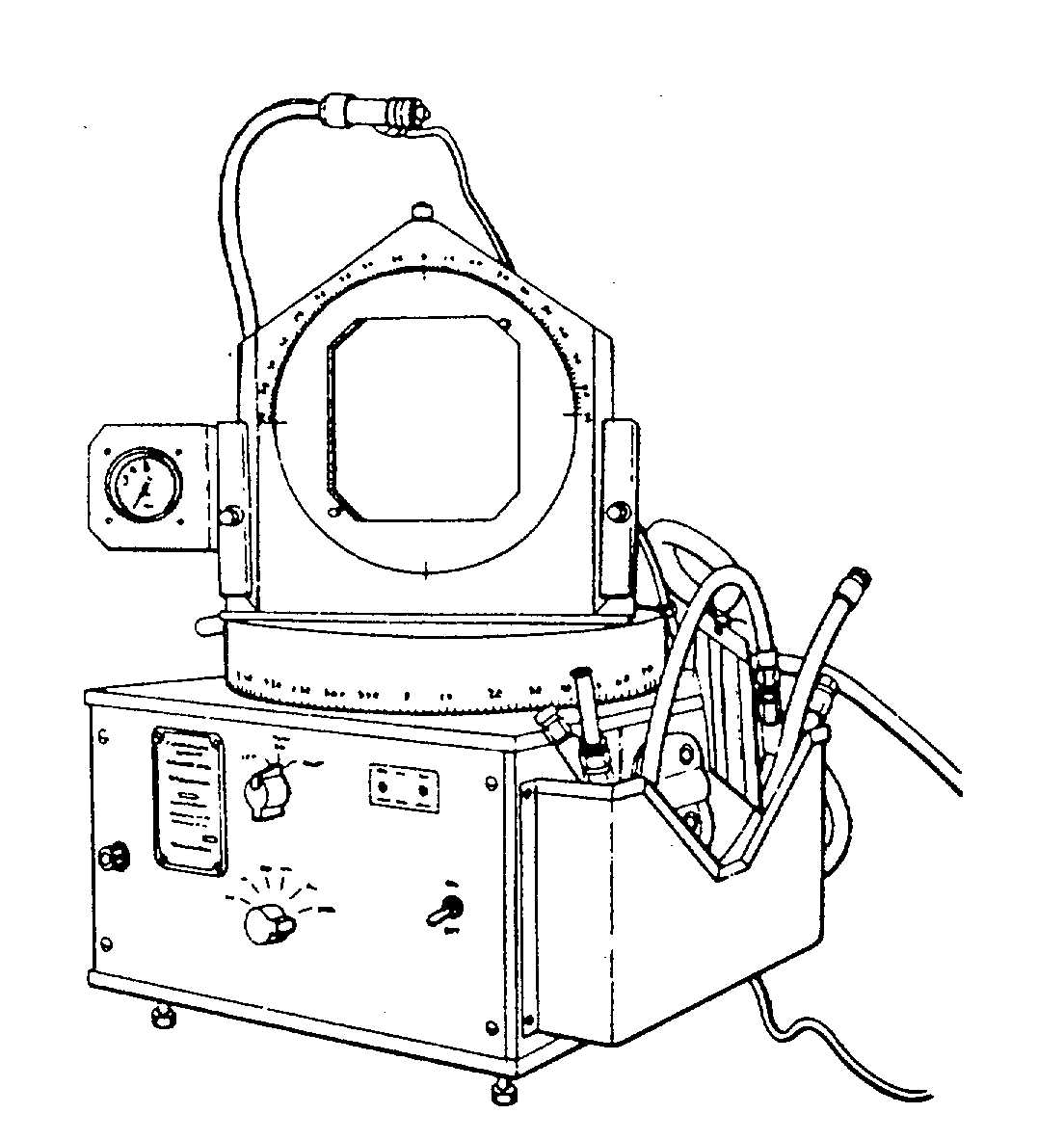

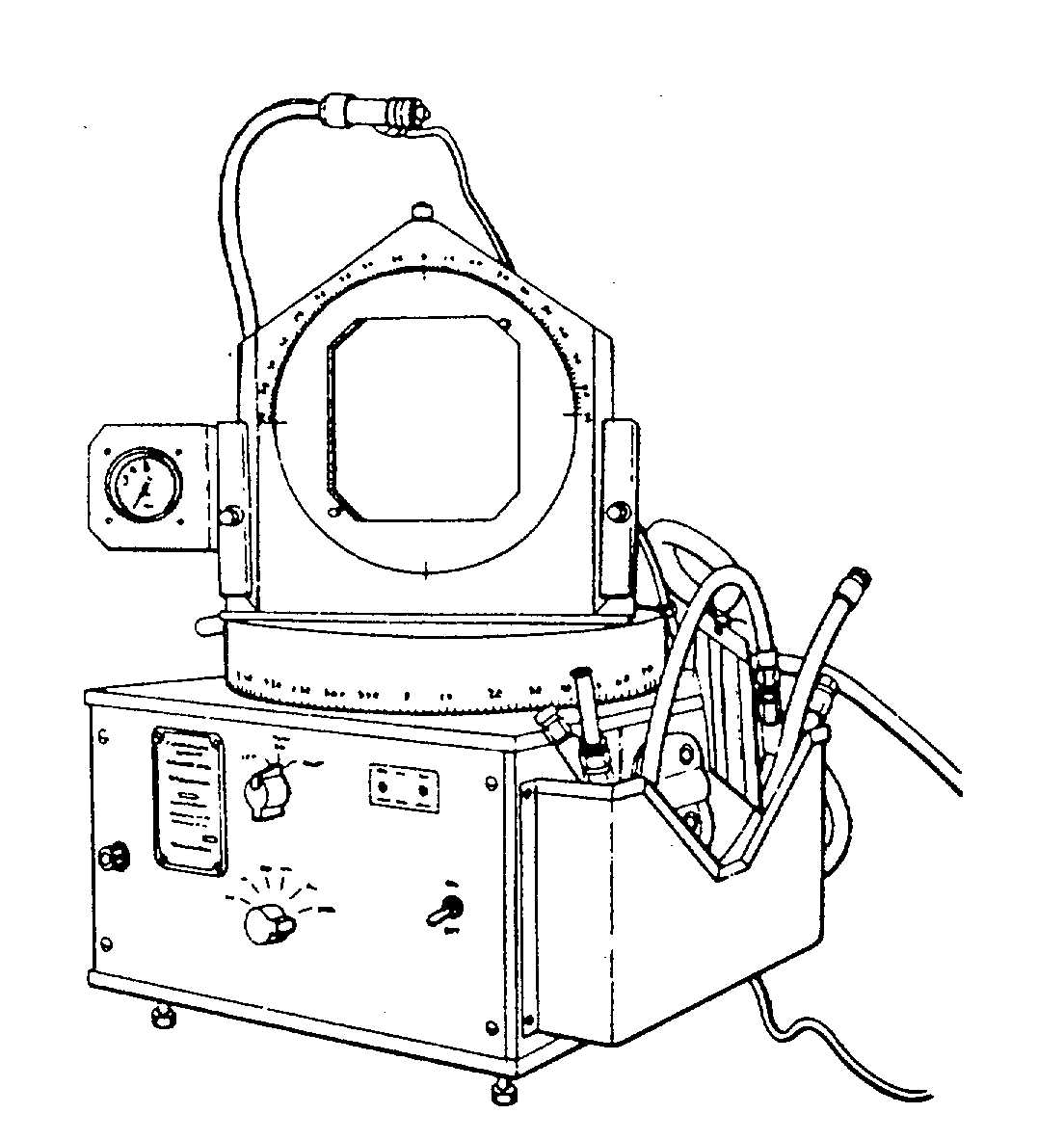

c. Turntable Instrument Tester. The turntable

instrument tester, as shown in figure 4-4, is used for

testing gyroscopic instruments that are not required to

indicate aircraft attitude.

(1) Inspection. Periodic inspection of the

unit is required after every 200 hours of operation. The

only inspection required is for chipped, broken, or

cracked gears and components.

Figure 4-4. Turntable Instrument Tester

4-5