TM 1-1500-204-23-4

method, and the solid color band, the alternate method.

Identification tapes will be applied to plumbing lines and

electrical conduits of all Army aircraft.

(a) Printed-symbolized tape system. This

latest and preferred system utilizes printed colored tape

(1 inch wide) with geometrical symbols. The main

function of the line is printed on the tape.

(b) Solid color band system. This alternate

system consists of the use of one, two, or three bands of

1/2-inch wide solid colored tape wrapped on various

lines for identification. .

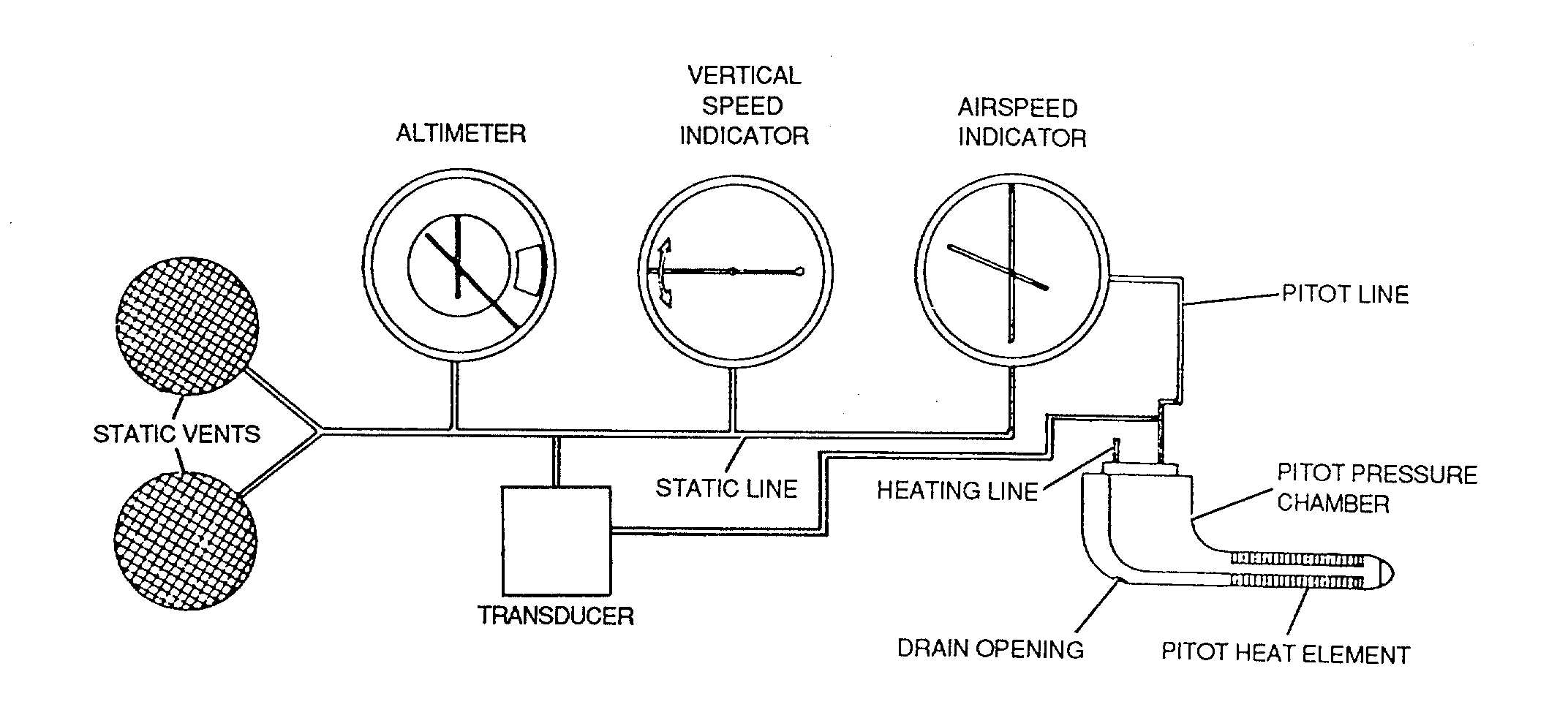

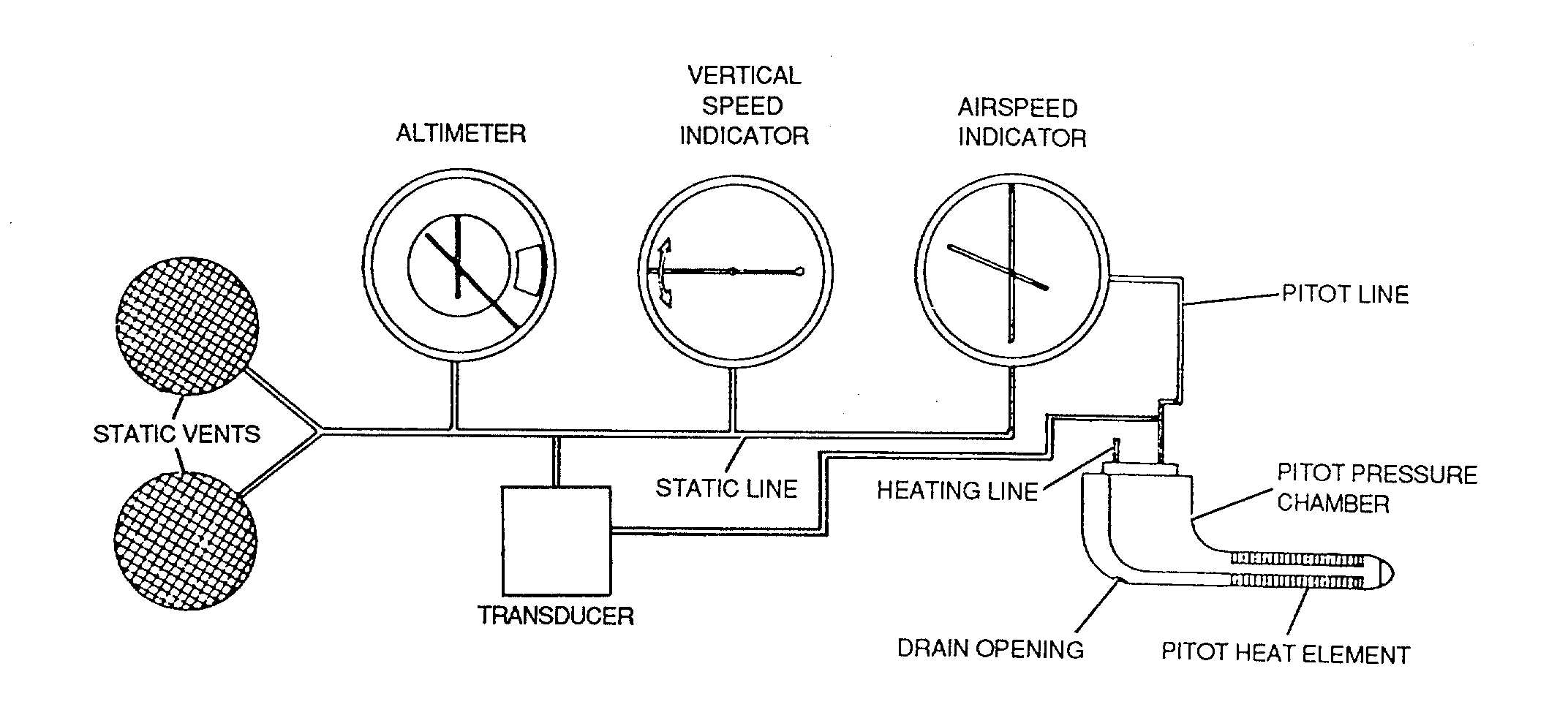

c. Pitot Static System. The pitot static system, as

shown in figure 4-7, consists of pitot-static tubes or pitot

tubes with static pressure ports or vents and their related

heaters, if any, and includes lines, tubing, water drains

and traps, and selector valves. Pressure actuated

indicators such as the altimeter, airspeed, and rate-of-

climb indicators, and control units such as air data

transducers, and automatic pilots may be connected to

the system.

(1) Principles of operation. Ram pressure

enters the pressure line through an opening at the

forward end of pitot tube and passes through the

pressure line to the airspeed indicator. Static pressure

is passed through the static pressure line to the vertical

velocity indicator, altimeter, and airspeed indicator static

pressure connections.

(2) Inspection of System. Inspect air

passages in the systems for water, paint, dirt or other

foreign matter. Remove obstructions in accordance with

applicable maintenance manual.

(a) Required equipment. A pitot static

system tester, as shown in figures 4-8 and 4-9, is

needed to complete pitot static system tests.

(b) Pitot line leak test procedures.

Pitot line leak test connections are shown in figure 4-8.

Do tests using the procedures that follow:

1

Seal pitot tube drain holes air

tight with pressure sensitive tape, Federal Specification

A-A-883.

CAUTION

Do not apply suction to pitot lines

or

pressure

to

static

lines.

Damage to bellows, indicators,

and computer equipment may

occur.

(3) System Leak Testing. Pitot-static leak

tests should be made with all instruments connected to

assure that no leaks occur at instrument connections.

Such tests should be made whenever a connection has

been loosened or an instrument replaced. Pitot systems

should be tested in accordance with the aircraft

manufacturer's instructions. If the manufacturer has not

issued instructions for testing pitot systems, the

following may be used:

Figure 4-7. Pitot Static System

4-10