TM 1-1500-204-23-4

2

Slowly apply pressure to pitot

line until the airspeed indicator reads normal cruising

speed. Use appropriate power supply in accordance

with pilot-static system being tested. Pinch off pressure

supply at flexible tube.

3

Tap indicator to remove friction

effects. When indicator pointer drops more than 10

miles an hour (8.7 knots) in 1 minute, a leak is indicated.

Repair faulty connections or cracks in pitot lines as

necessary.

4

Remove test apparatus from

pitot tube.

5

Remove tape from the pitot

tube drain holes.

(c) Static line leak test procedures.

Static line leak test connections are shown in figure 4-9.

Do tests using the procedures that follow:

1

Set altimeter pointers to field

elevation.

2

Tape unused static ports.

CAUTION

When applying suction to the

static line, the airspeed indicator

and computer equipment may be

damaged.

3

Slowly apply suction to static

line until airspeed indicator reaches full scale. Close

vacuum source and tap altimeter at same time until rate

of climb stabilizes at zero. After stabilization, the

altimeter should not drop more than 100 ft. in the next

minute.

4

Slowly remove suction from

static lines until altimeter reads field elevation.

5

Remove test apparatus from

static port.

6

Remove tape from static ports.

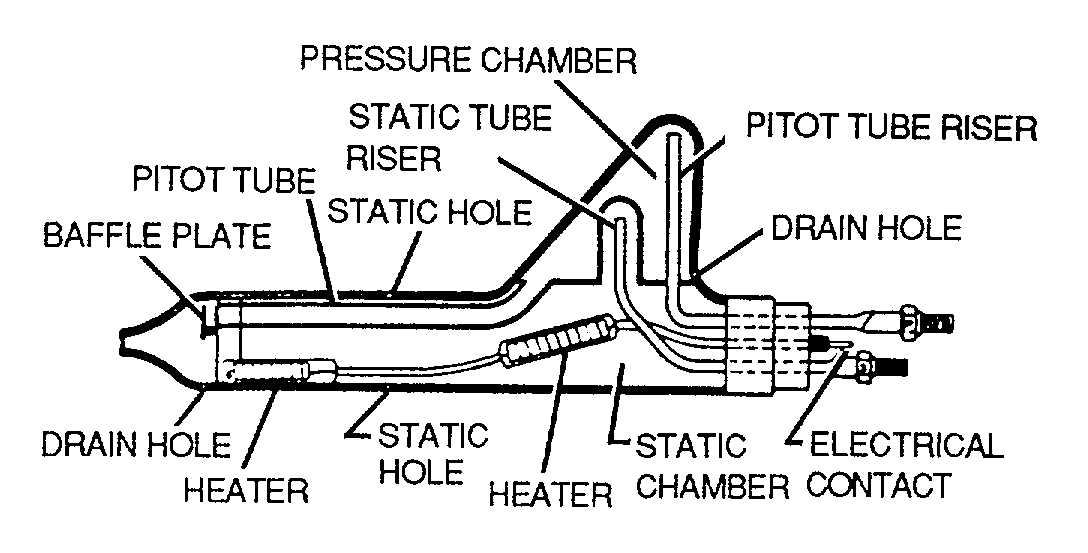

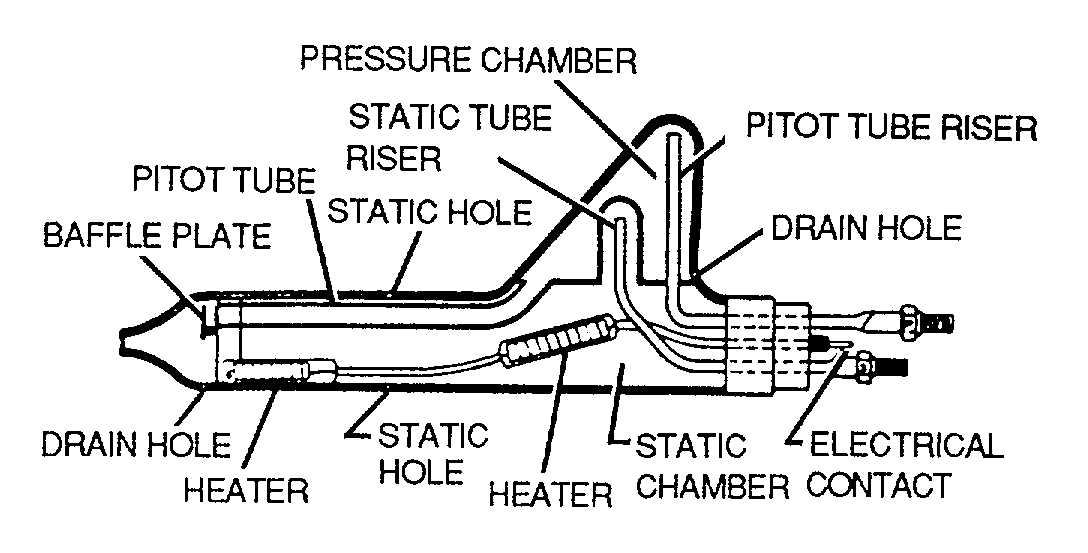

d. Pitot Static System Heater. Pitot static tubes,

as shown in figure 4-10, are provided with heaters to

prevent icing during flight. Principles of operation and

testing procedures are described in the following

paragraphs.

(1) Principles of operation. During ice-

forming conditions, pilot heat is selected by a switch in

the cockpit. Heating elements heat the pitot head to

provide pitot anti-icing.

(2) Testing. Test pitot static system heater

using the following paragraphs.

(a) Required equipment. No special

required equipment is needed.

(b) Pitot static heater test procedures.

Test using the procedures that follow:

WARNING

Exercise caution when touching

pitot tube with fingers as serious

burns may result.

1

Turn aircraft battery switch ON.

2

Turn pilot heater switch ON and

check for heat rise by touching pitot head lightly with

fingers.

3

When elements do not heat

within 2 minutes, and wiring is correct, pitot head must

be replaced.

e. Airspeed Indicators. Principles of operator and

testing procedures are described in the following

paragraphs.

(1) Principles of operation. The airspeed

indicator, as shown in figure 4-11, shows the speed of

the aircraft relative to the air mass through which it is

flying. Each instrument is a pressure-sensitive unit

actuated by the differential between impact and static air

pressures. The impact (pitot) pressure is transmitted

from the pitot head to the inside of the pressure-

sensitive diaphragm in the instrument case, while static

pressure is applied to the interior of the case.

Figure 4-10. Pitot Tube

4-12