TM 1-1500-204-23-6

•

Under emergency conditions, any steel bolt or screw of the same nominal diameter as the hole having a tensile

strength of 125,000 psi may be used, provided it is replaced with the correct fastener within 25 flight hours.

t.

Substitutions for Jo-Bolts and V-Bolts. These bolts can be replaced by the bolts listed in table 2-7. Jo-Bolts are

numbered in relation to their diameter. The asterisk denotes the length dash number. This type of fastener is used

primarily in blind installations.

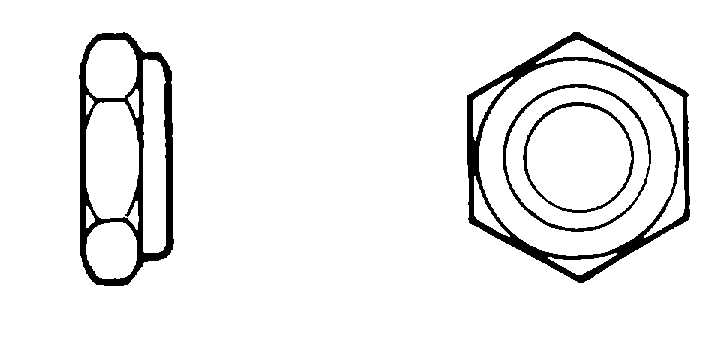

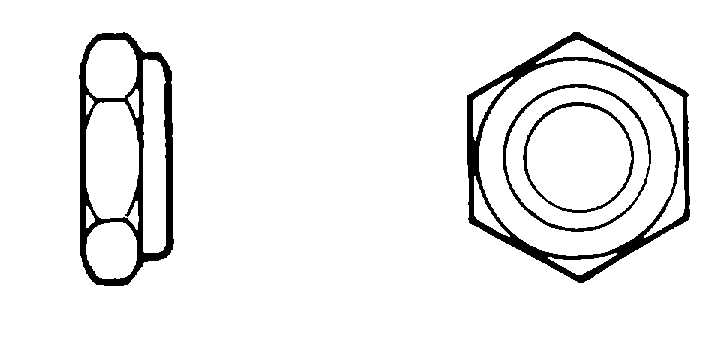

2-3.Nuts. The following paragraphs present the various families of aircraft structural nuts, their types, means of

identification, and proper applications.

a.

Self-Locking Nuts. Self-locking nuts are used on aircraft to provide tight connections which will not shake loose

under severe vibration. These nuts must meet the critical specification as to strength, corrosion resistance, and

temperature range set forth in MIL-N- 25027 before they can be used. Standard nuts are shown in figures 2-14 and 2-15.

(1) Types. The two general type self-locking nuts currently in use are designated as the all-metal type and the

nonmetallic insert (fiber or nylon) type. Each obtains its locking quality through a different means as indicated by its

respective title.

(a) All-metal self-locking nuts. Locking action of the nut depends upon the ability of the metal to recover its

size and shape when the locking action and the load-carrying portion are engaged by bolt or screw threads. When used,

the following criteria must be met:

Table 2-7. Jo- and V-Bolt Substitution

Jo-Bolt

V-Bolt

Hole dia

part No

part No.

(inches)

WP 164

BA5A*H

0 164 to 0.168

WP 200

BA6A*H

0.199 to 0.203

WP 260

BA8A*H

0.261 to 0.265

WP 312

BA1 OA*H

0 313 to 0.317

WP 164

BA5A*F

0.164 to 0.168

WP 200

BA6A*F

0.199 to 0.203

WP 260

BA8A*F

0 261 to 0 265

WP 312

BA1 OA*F

0 313 to 0.317

•

All-metal self-locking nuts shall not be reused in critical applications where failure could cause loss of the aircraft or

endanger life.

•

When absolutely necessary, all-metal self- locking nuts may be reused in noncritical applications only, and then only

after having equalled or exceeded the minimum breakaway torque value for the applicable size nut, as given in table

2-8.

•

High temperature, MS20500 or approved equivalent, and silver-plated, all-metal, self-locking nuts will not be

subjected to temperatures in excess of 12000F (6480C).

•

Do not subject cadmium-plated, all-metal, self-locking nuts to temperatures in excess of 4500F (2320C).

•

Do not run a thread-cutting tap through an all-metallic, self-locking nut, as this will destroy the self-locking properties.

(b) Nonmetallic insert self-locking nuts. The nonmetallic fiber or nylon insert is pressed within the inside

diameter of the nut proper. When a screw or bolt is installed, the insert stretches and forces contact between itself and

the bolt or screw threads, producing the locking action. When used the following criteria must be met:

•

Nonmetallic self-locking nuts shall not be reused in critical applications where failure could cause loss of the aircraft

or endanger life.

•

When absolutely necessary, nonmetallic self-locking nuts may be reused in non- critical applications only, and then

only after having equalled or exceeded the minimum breakaway torque value for the applicable size nut, as given in

able 2-8.

Figure 2-14. Self-Locking Thin Nut

Change 1 2-25