TM 1-1500-204-23-6

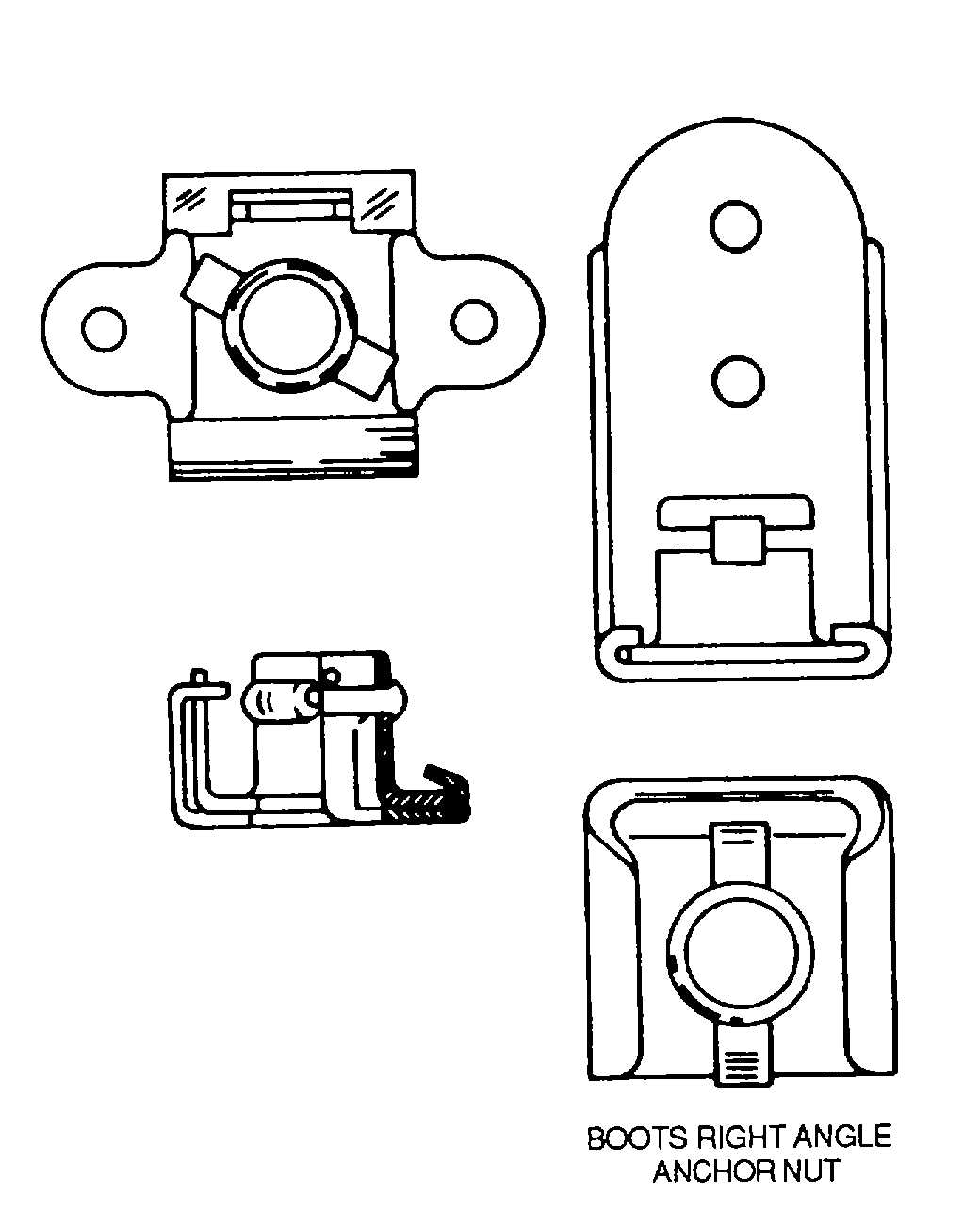

Figure 2-17. Floating Anchor Nuts

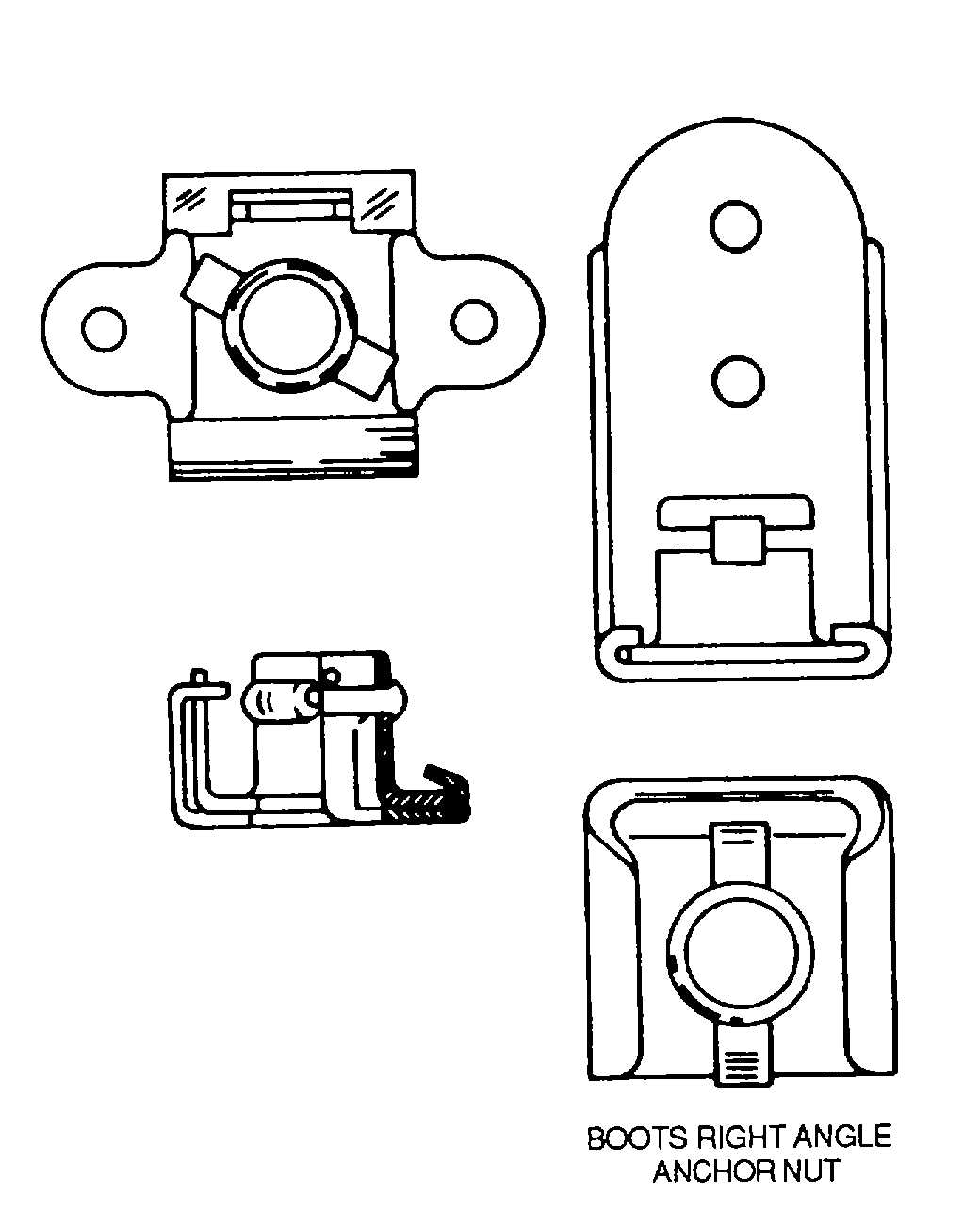

Figure 2-18. Plate Nut Styles

CAUTION

Self-locking nuts shall not be reused in applications where failure could

cause loss of the aircraft or danger to life.

(3) Installation. Self-locking nuts, like most aircraft parts, are precision-built. To perform their job effectively, they

must be handled properly.

(a)

Instructions. The procedures for installing self-locking nuts are as follows:

1 Since self-locking nuts are purposely made with a tight locking insert, a wrench must be used to tighten

them.

2 Start nut and bolt connections by hand to prevent cross threading.

3 Use drift pin carefully when lining up nut and screw holes to avoid damaging nut.

4 Prevent overstressing bolt and nut threads by using a torque wrench and recommended torque values

specified in table 2-9.

5 Use proper tools at all times. Socket and box end wrenches are preferred to open end wrenches as they

will not damage the corners of the nuts.

(b)

Limitations. Self-locking nut installation limits are shown in figure 2-21. The limit criteria as

applicable are as follows:

•

Round- or chamfered-end bolts or screws, as shown in figure 2-21, must extend at least the full round or

chamfered area plus one thread pitch through the nut.

•

Flat end bolts or screws, as shown in figure 2-21, shall extend at least two thread pitches through the nut.

•

Nuts, made to the minimum height, that are used with bolts of maximum length may give the indication

that too many threads are exposed and the grip of the bolt is pushing against the face of the nut. There is

no assurance that this is not true until the nut is removed and inspected for scratches.

2-29