TM 1-1500-204-23-6

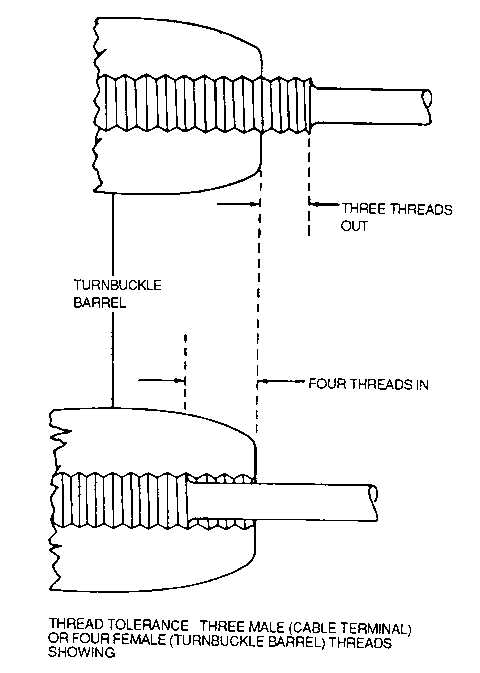

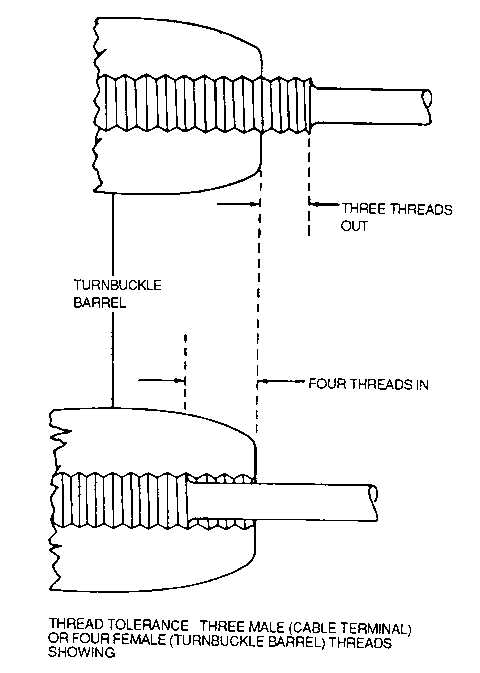

Figure 2-73. Turnbuckle Thread Limits

CAUTION

Cotter pin shall be new upon each application. Old cotter pins may fail causing damage to component

NOTE

·

Use brass cotter pins In areas where nonmagnetic material Is required Use corrosion-resistant cotter

pins In areas where corrosion-resistant material is required

·

Avoid kinks or sharp bends In cotter pins.

(1) Install cotter pin in castellated nuts and bolts with head parallel to slot in nut, as shown In figure 2-77.

This Is the preferred method

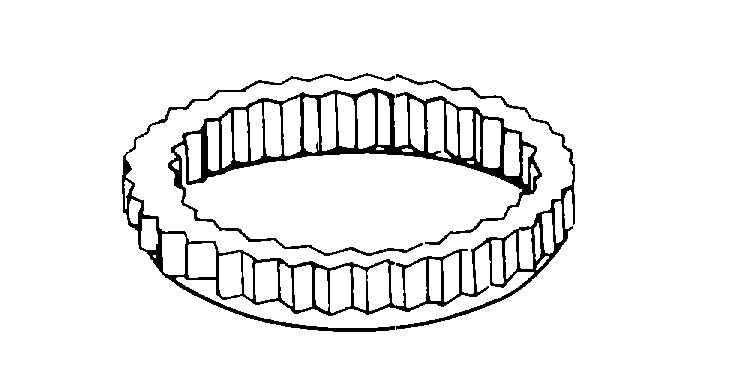

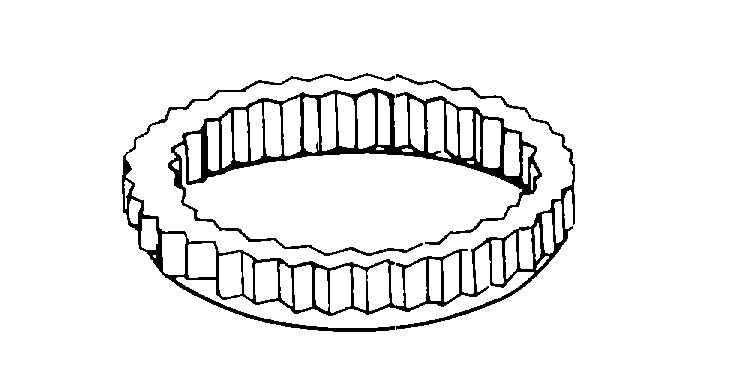

Figure 2-74. Lockring

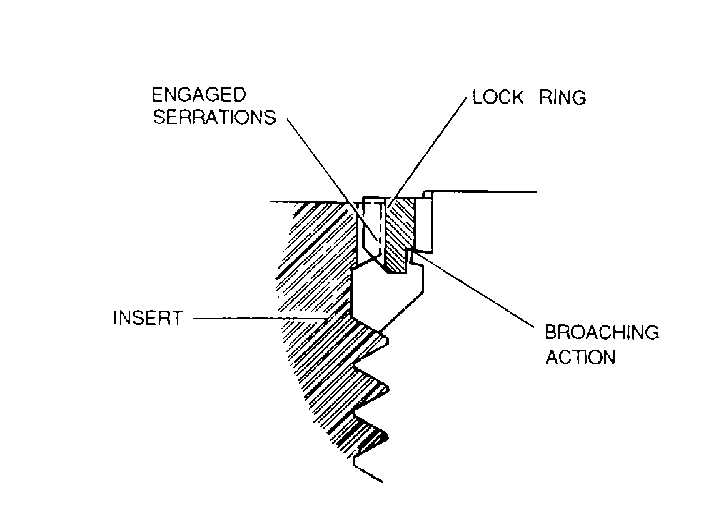

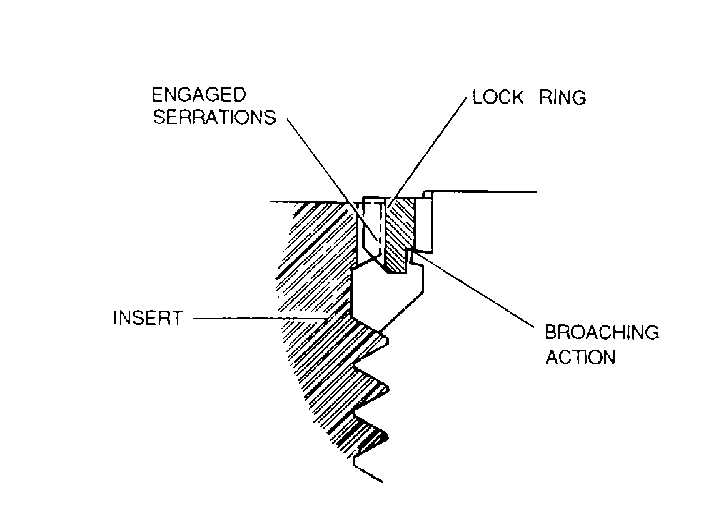

Figure 2-75. Lockring Principle

(2) Install cotter pin with head horizontal to slot In nut as an alternate installation, as shown In figure 2-77.

This method will be followed where there is danger of snagging hands, clothing, or equipment of flight

personnel on sharp ends of cotter pin or because of installation difficulties.

NOTE

In event more than 50 percent of cotter pin diameter Is above castellation, a washer shall be used under

nut, or a shorter fastener shall be used.

2-74