TM 1-1500-204-23-6

(2) Tightening new nuts. It is good practice in torquing, especially for new bolts and nuts, to first tighten

the fastener to the desired torque value and then loosen the nut or bolt by backing off approximately

one-half turn. Then retighten to the specified torque value. This aids in cleaning and smoothing the

threads, and results in more accurate torque.

(3) Aligning for cotter pins. Never loosen a castellated nut to obtain alignment. When a nut is to be

secured to a fastener with a cotter pin or safety wire, the nut should be tightened to the low limit of the

specified torque range and the hole aligned, If necessary, by tightening operation. Where only a single

torque value is specified and the hole does not align, further tightening to align the next slot is

permissible In either case, the maximum torque allowed by table 2-9 must not be exceeded.

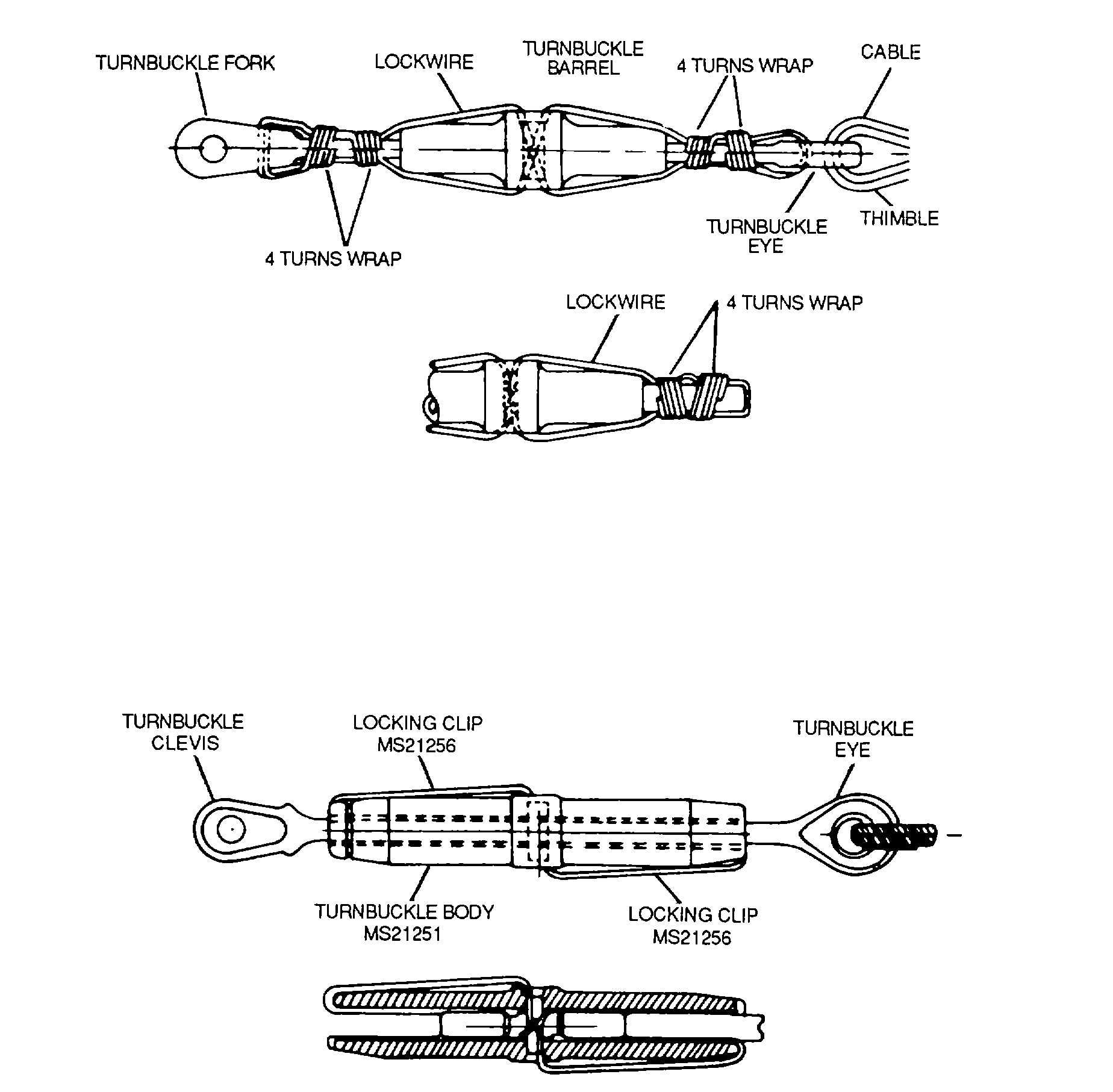

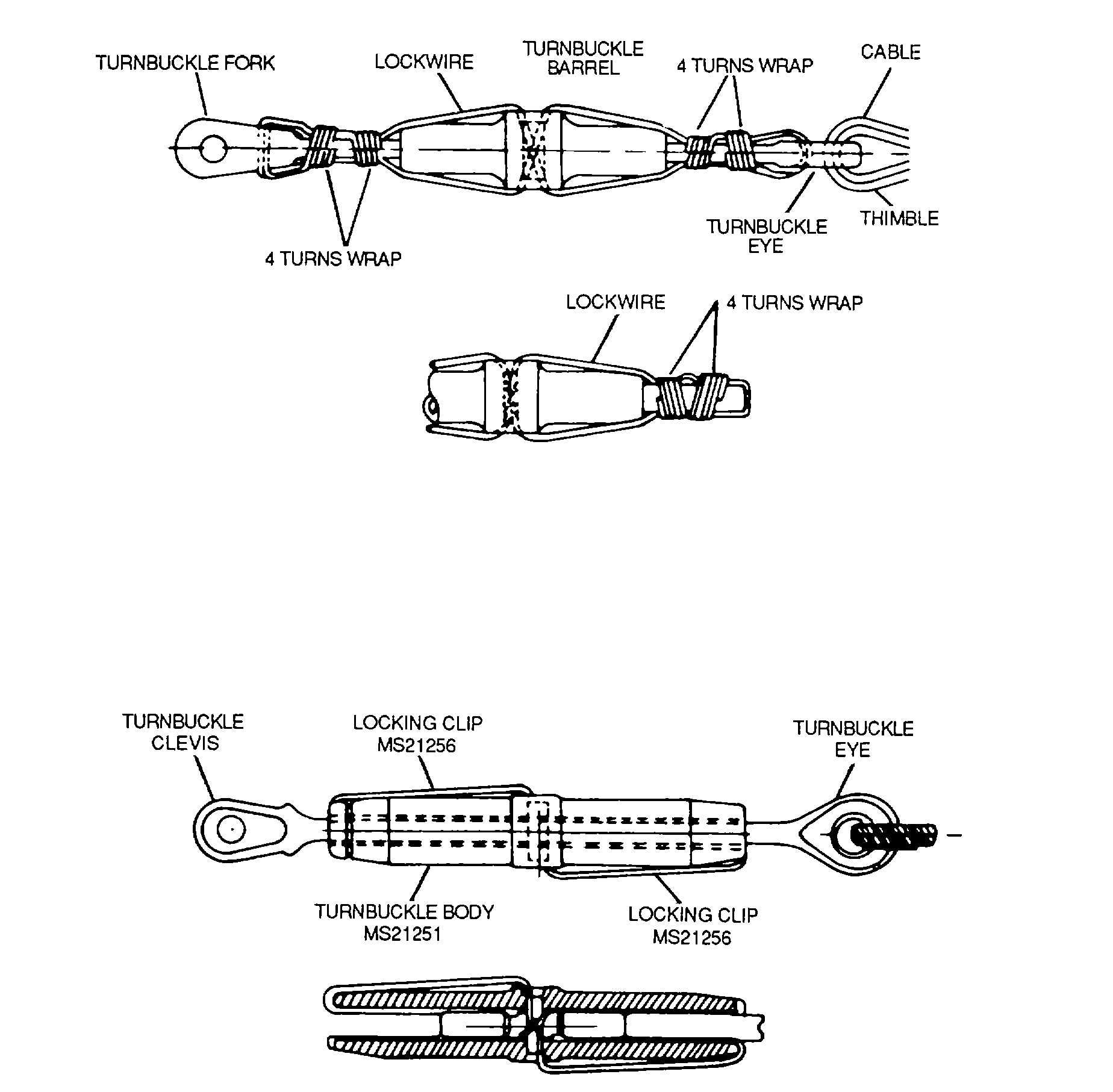

Figure 2-80. Typical Turnbuckle Assemblies

2-82

TM 1-1500-204-23-6