TM 1-1500-204-23-9

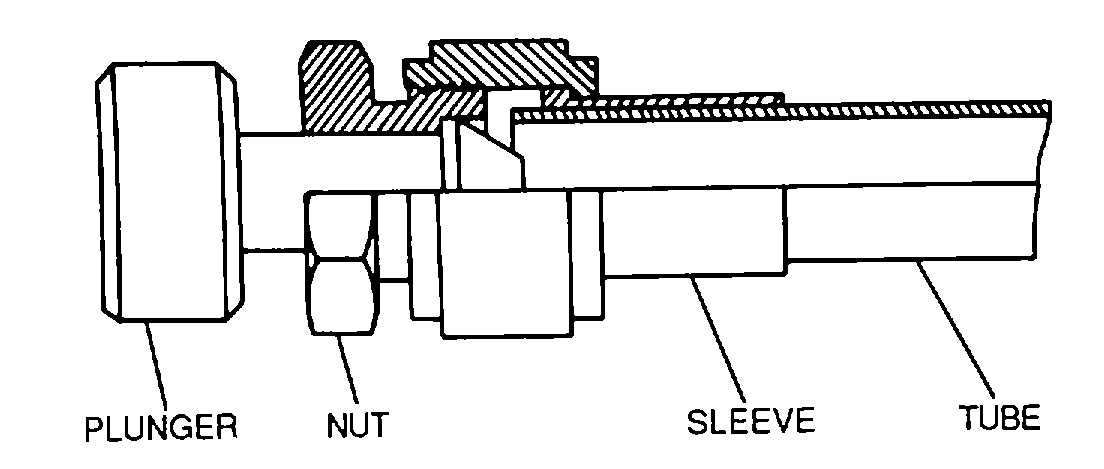

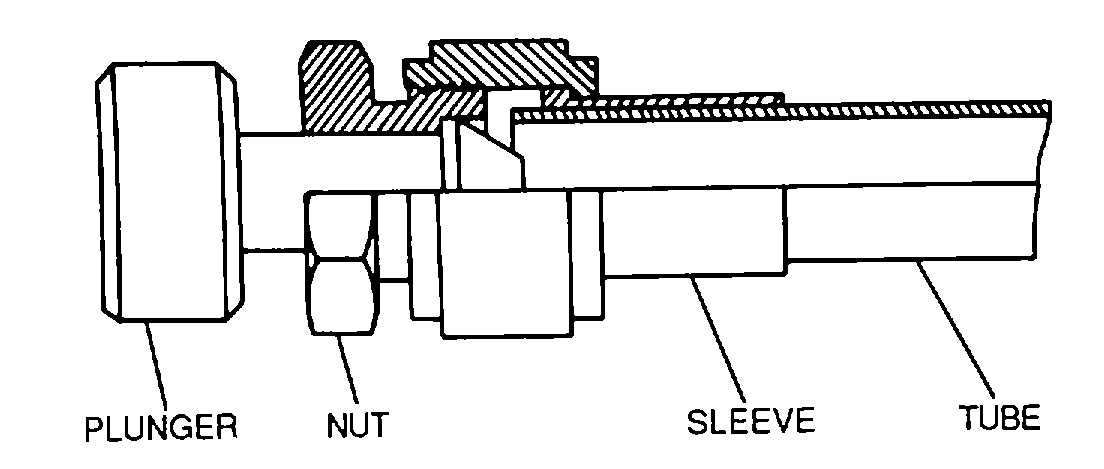

Figure 4-121. Individual Flaring Tool

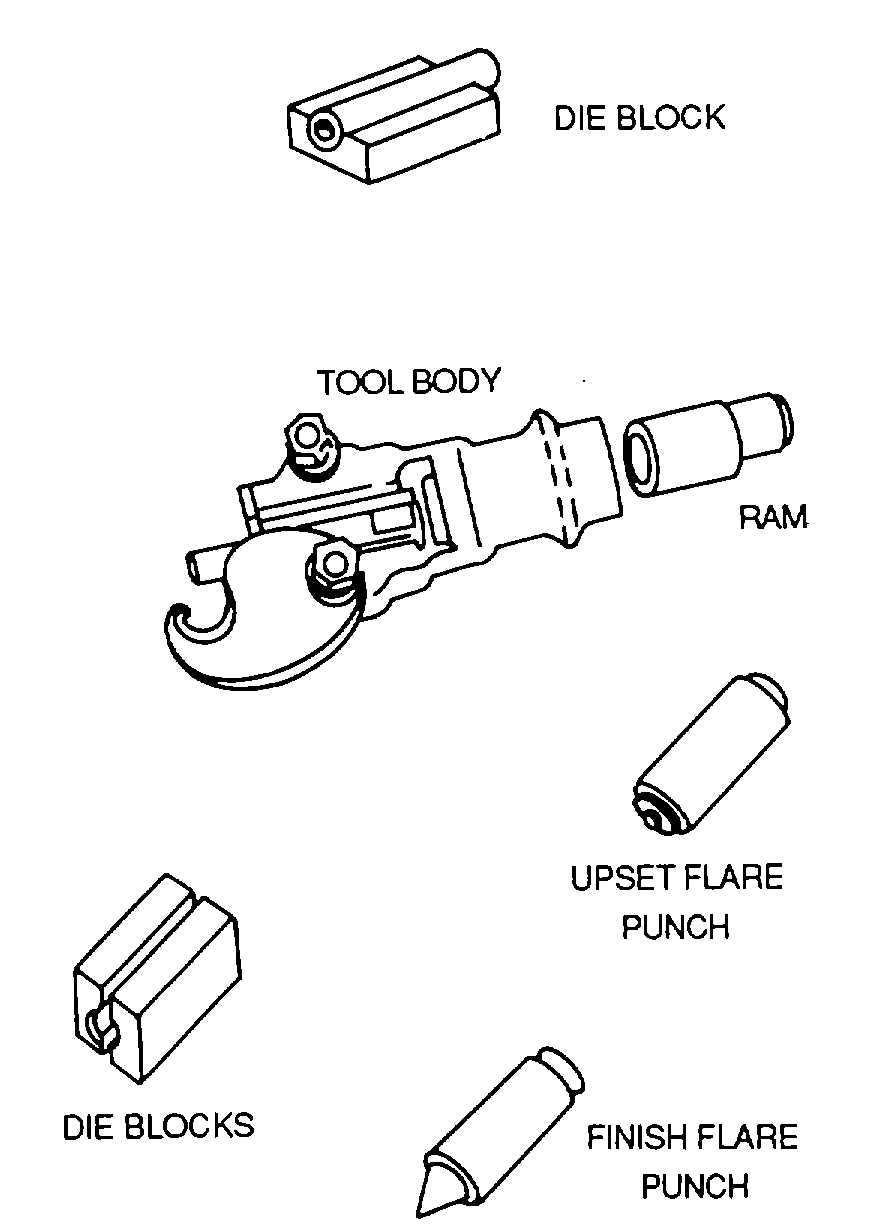

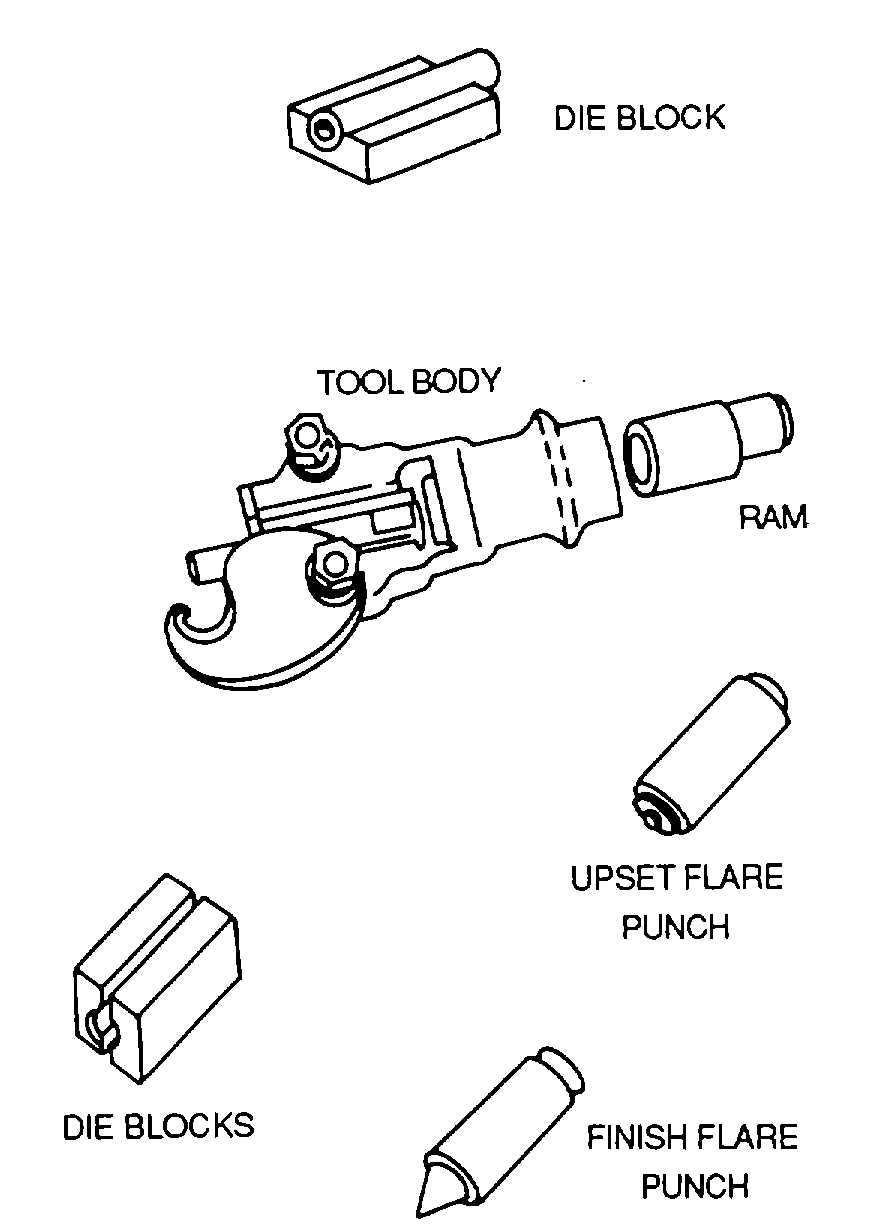

Figure 4-122. Double-Flaring Tool

b.

Use. The following paragraphs provide

procedures for flaring tubing using the flaring tools

described

above.

NOTE

Refer to TM 1-1500-204-23-2 for specific

flaring procedures and requirements. The

following

instructions

are

general

in

nature and are intended to illustrate the

operation of these tools.

(1)

Combination flaring tool. To flare a tube

using a combination flaring tool, proceed as follows:

(a)

Loosen the die block clamp screws

and open the die block.

(b)

Insert the tubing to be flared into the

die block. Allow 1/16 inch to extend above the die

block, and tighten the die block clamp screws.

(c)

Place flare cone over the end of the

tube.

(d)

If the flare cone is activated by a

screw, tighten it until the end of the tubing is forced into

the countersunk hole in the die block. If the tool has a

plunger, tap the plunger lightly with a hammer until the

metal assumes the shape of the countersunk hole.

NOTE

Rotate the plunger slightly after each

hammer blow to ensure a uniform flare.

(e)

When the desired flare is reached,

remove the flare cone from the tube.

(f)

Unscrew the die block clamp and

remove the tubing.

(g)

Inspect the flare for cracks or

breaks. If a crack or a break is detected, the tubing

must be cut and reflared.

(2)

Individual flaring tool. To flare a tube

using an individual flaring tool, proceed as follows:

(a)

Place the sleeve (MS20819) into

the nut (AN818) and screw the nut onto the tool.

(b)

Insert the tube through the sleeve.

(c)

Hold the tube and strike the head of

the plunger with a hammer.

NOTE

Rotate the plunger slightly after each

hammer blow to ensure a uniform flare.

(d)

Stop hammering when the flare

reaches the desired dimensions.

4-50