TM 1-1500-204-23-9

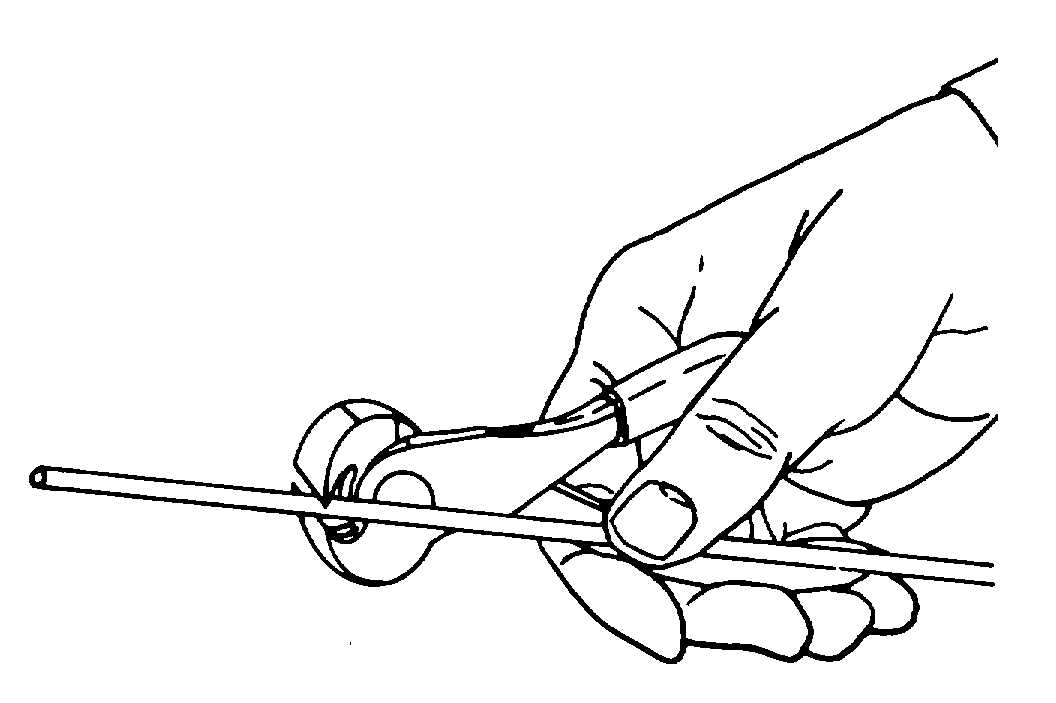

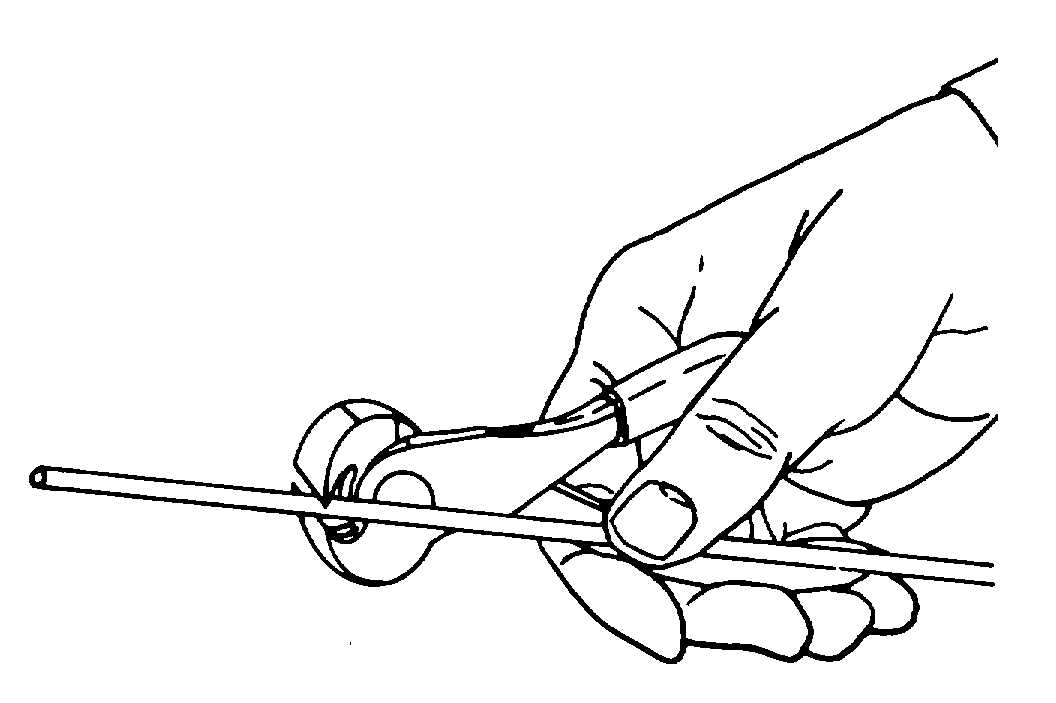

Figure 4-112. Cutting Wire

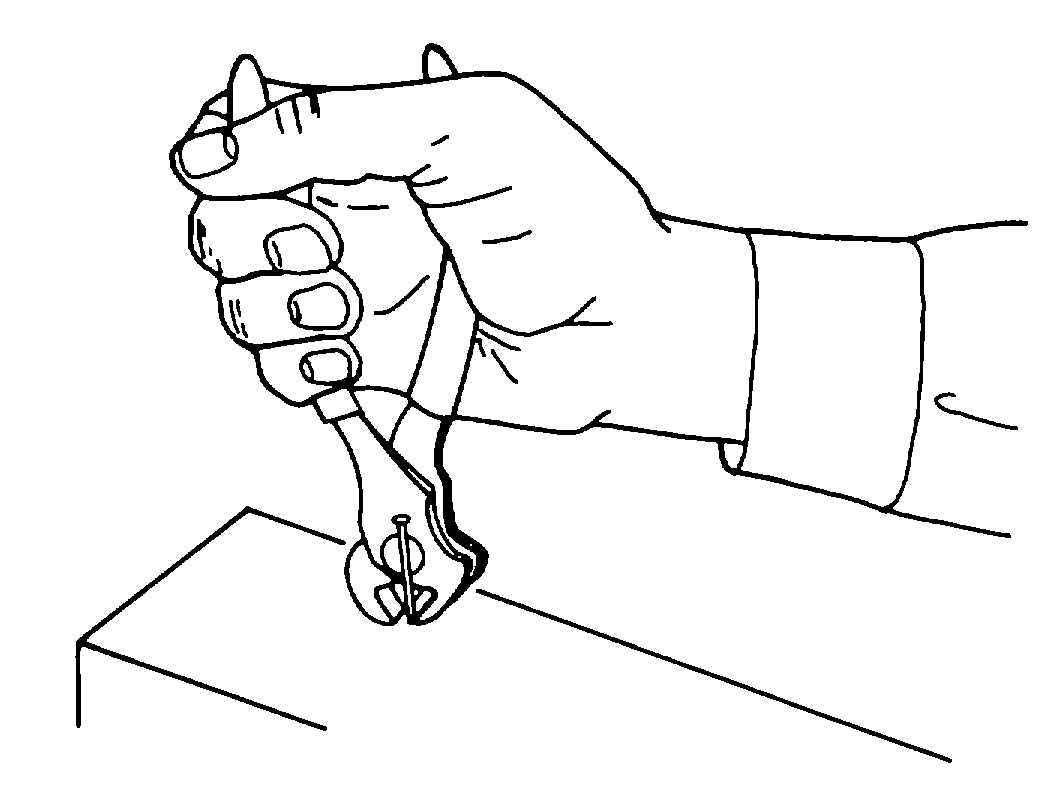

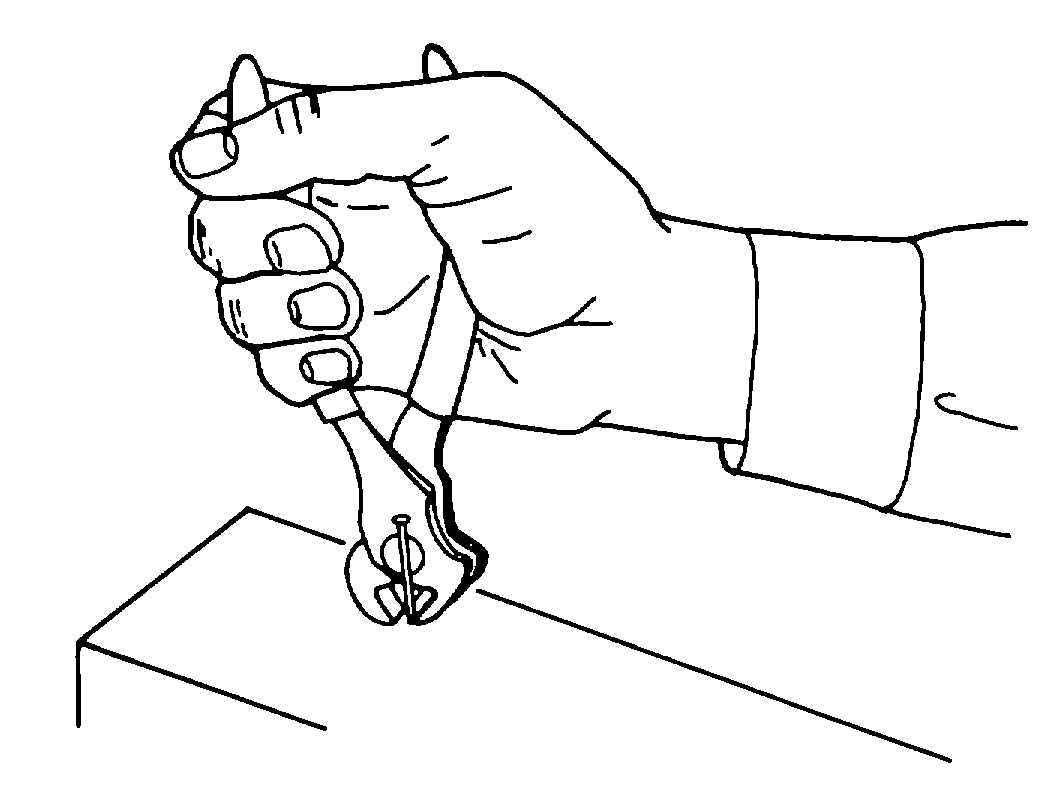

Figure 4-113. Flush Cutting

b.

Care. Observe the following practices for the

care and upkeep of nippers and pincers.

(1)

Keep tools clean at all times. Lubricate

the pivot screw or bolt with a drop of light oil.

(2)

Apply a thin coat of oil to prevent rust.

(3)

Store so that the cutting edges will not

come in contact with other tools.

4-23. Pipe and Tube Cutters. Pipe and tube cutters

are used to cut pipe or tubing to the length required for

fabrication. Pipe and tube cutters are similar in

appearance and operation. The essential difference

between pipe and tubing is that tubing has considerably

thinner walls.

a.

Description. Pipe and tube cutters have a

cutting wheel and two rollers which are located in a

position so that a pipe or tube may be held between

them. The rollers may be adjusted toward or away from

the cutting wheel by a hand-adjusted screw. This action

places pressure against the tube being cut, thereby

forcing it against the cutting wheel. Pipe and tube

cutters are described in the following paragraphs.

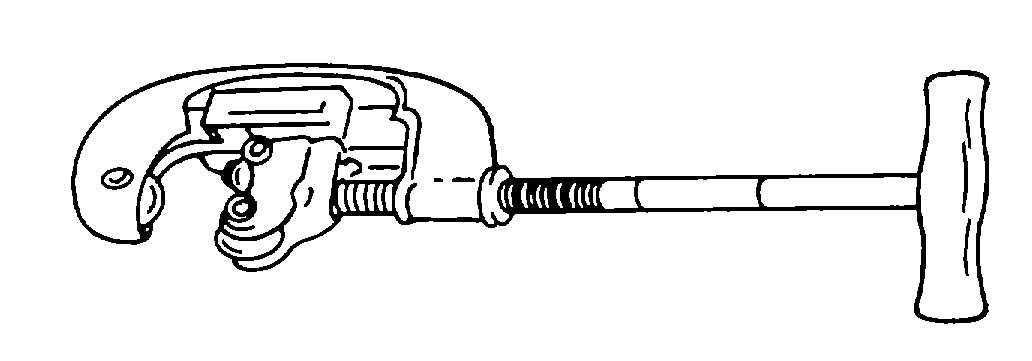

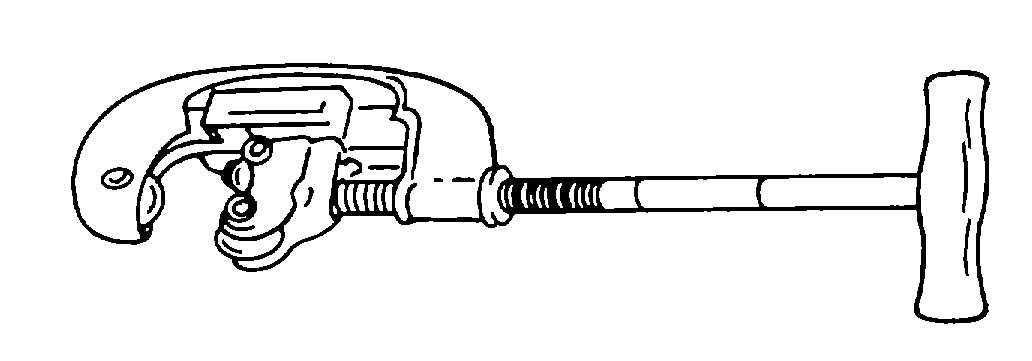

(1)

Pipe cutters. Pipe cutters are used to cut

pipe made of steel, brass, copper, wrought iron, and

lead. The two sizes of pipe cutters generally used in the

Army have capacities of 1/8 to 2 inches, and 2 to 4

inches. A typical pipe cutter is shown in figure 4-114.

Figure 4-114. Pipe Cutters

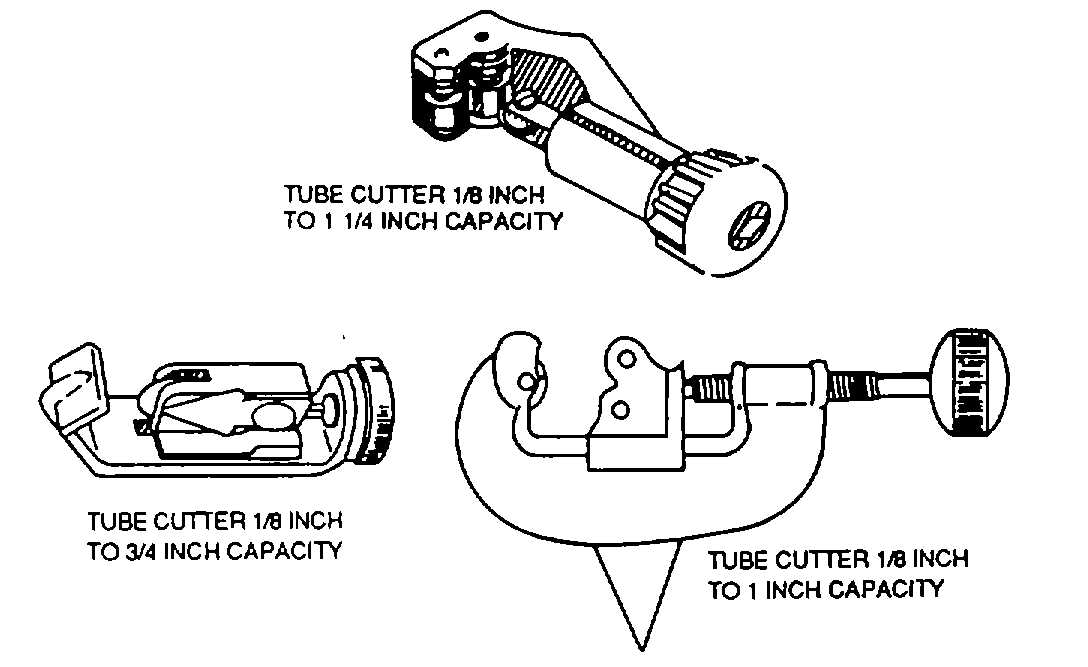

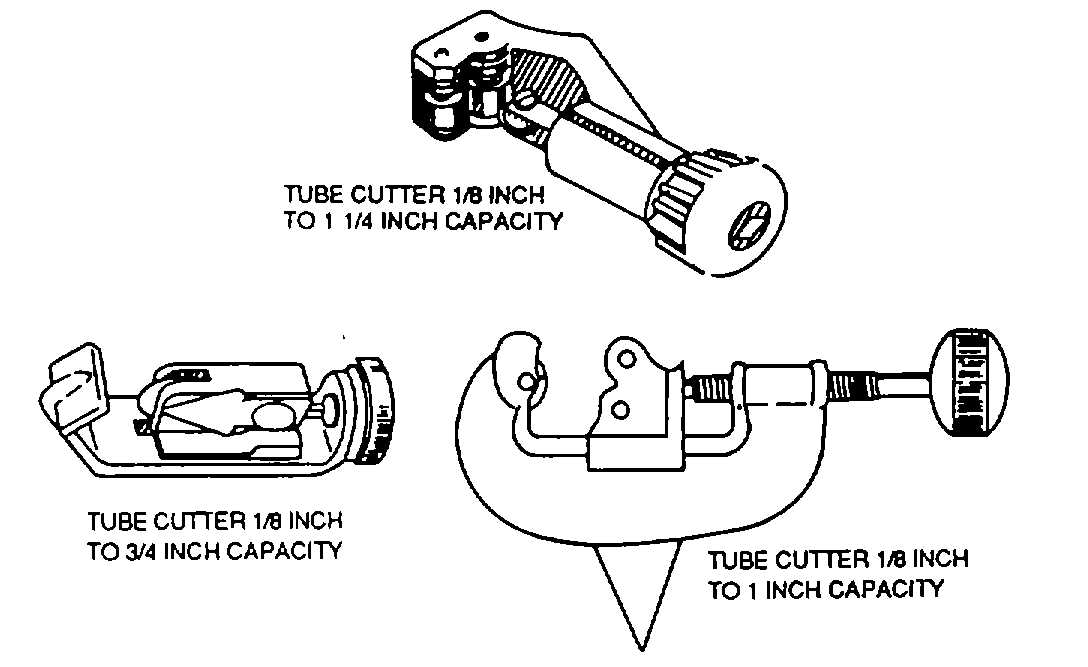

(2)

Tube Cutters. Tube cutters are used to

cut tubing made of iron, steel, brass, copper, and

aluminum. They resemble pipe cutters, except that they

are of lighter construction. Some tube cutters have

built-in portions in the body which are rotated in the

tubing after it is cut to eliminate any burrs, shown in

figure 4-115.

b.

Use. Because the operation of pipe and tube

cutters is so similar, and tubing maintenance is most

common in the repair of Army aircraft, the following

steps will provide procedures for the cutting of tubing.

Proceed as follows:

Figure 4-115. Tube Cutters

4-46