TM 1-1500-204-23-9

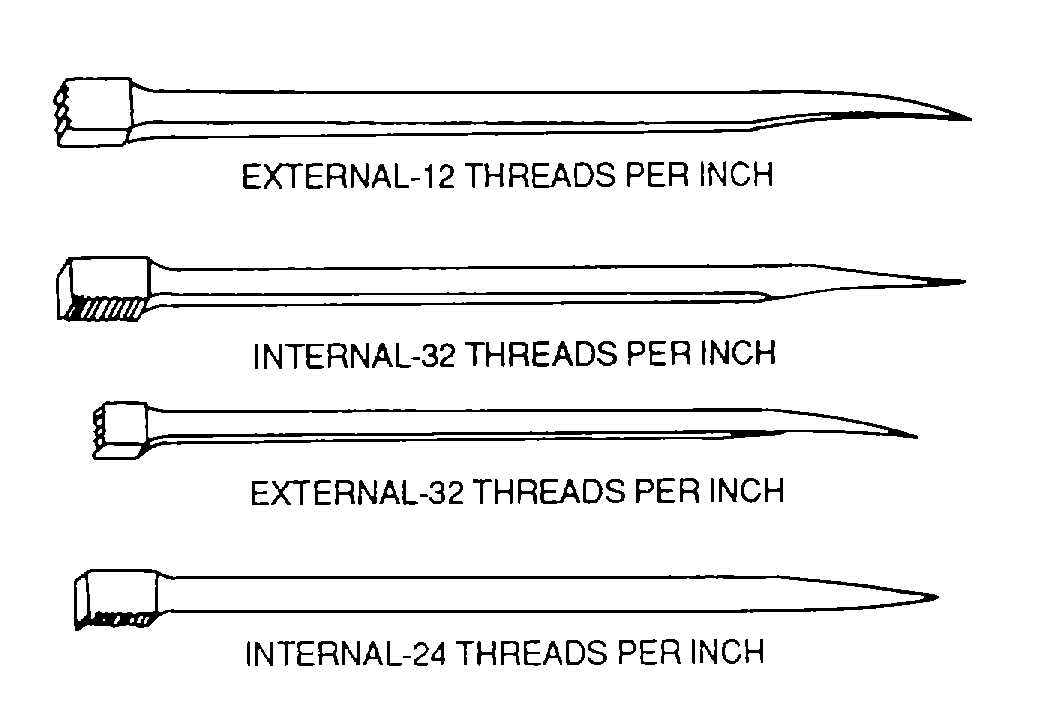

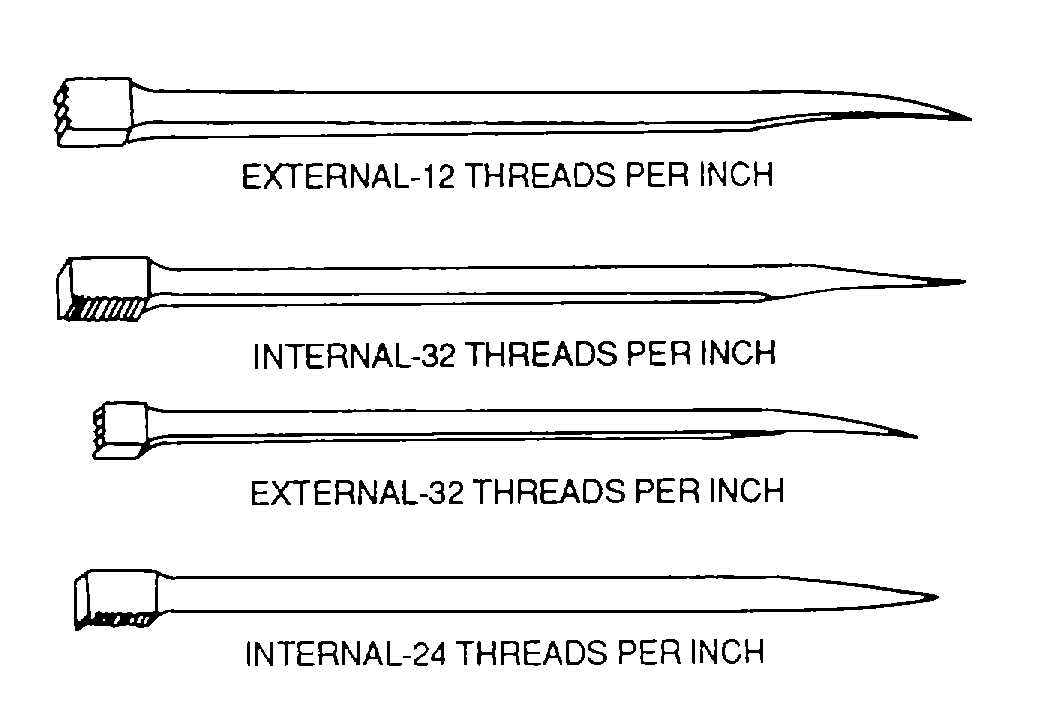

Figure 4-106. Thread Chasers

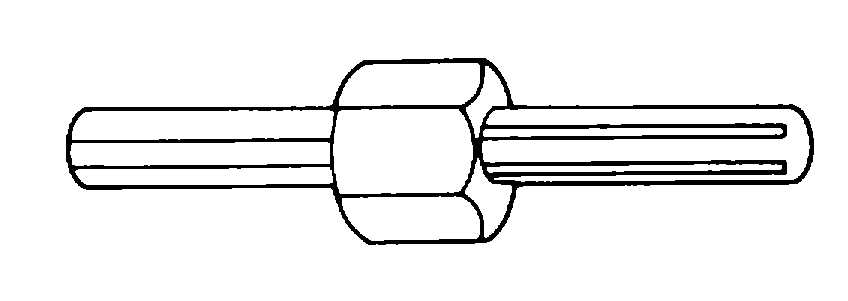

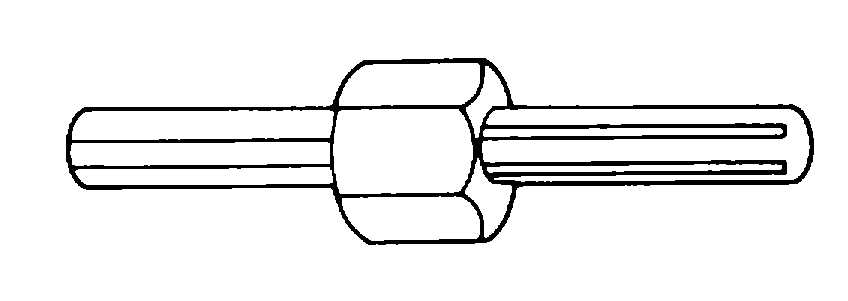

Figure 4-107. Straight Screw Extractor

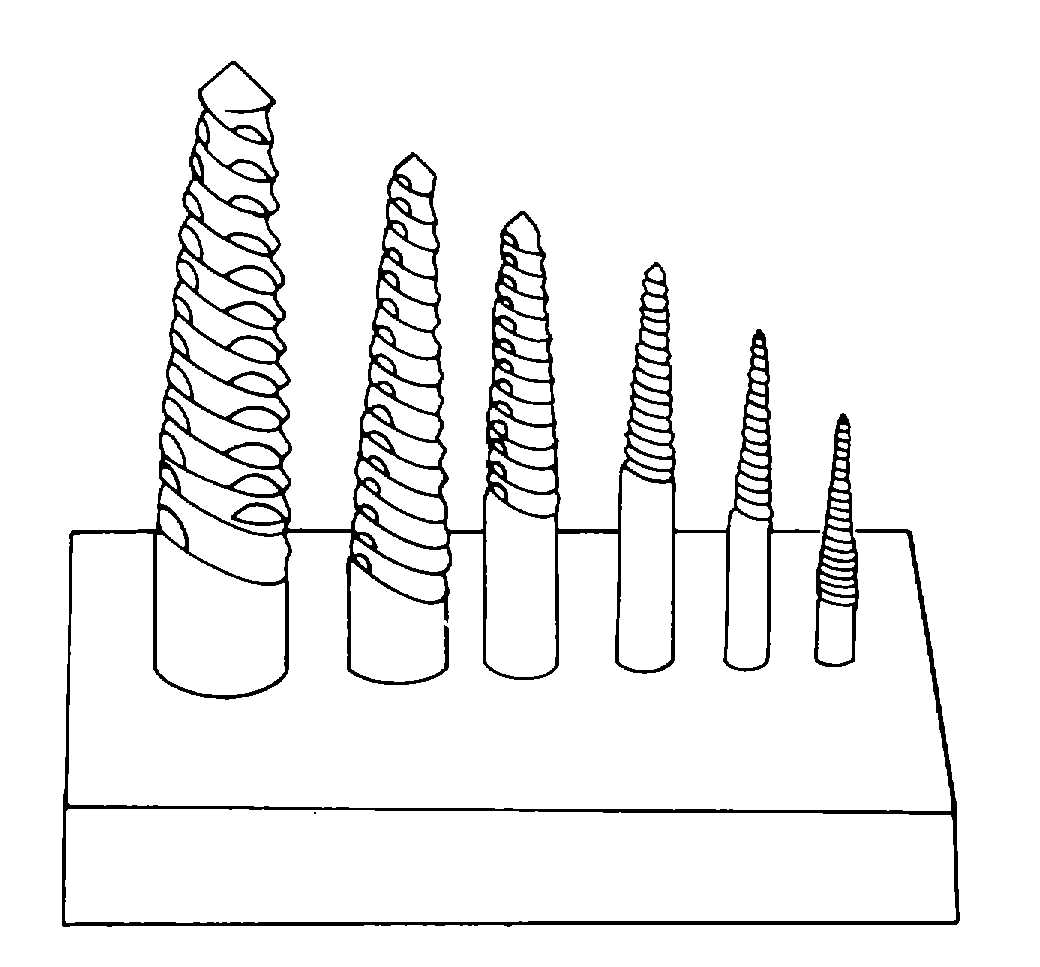

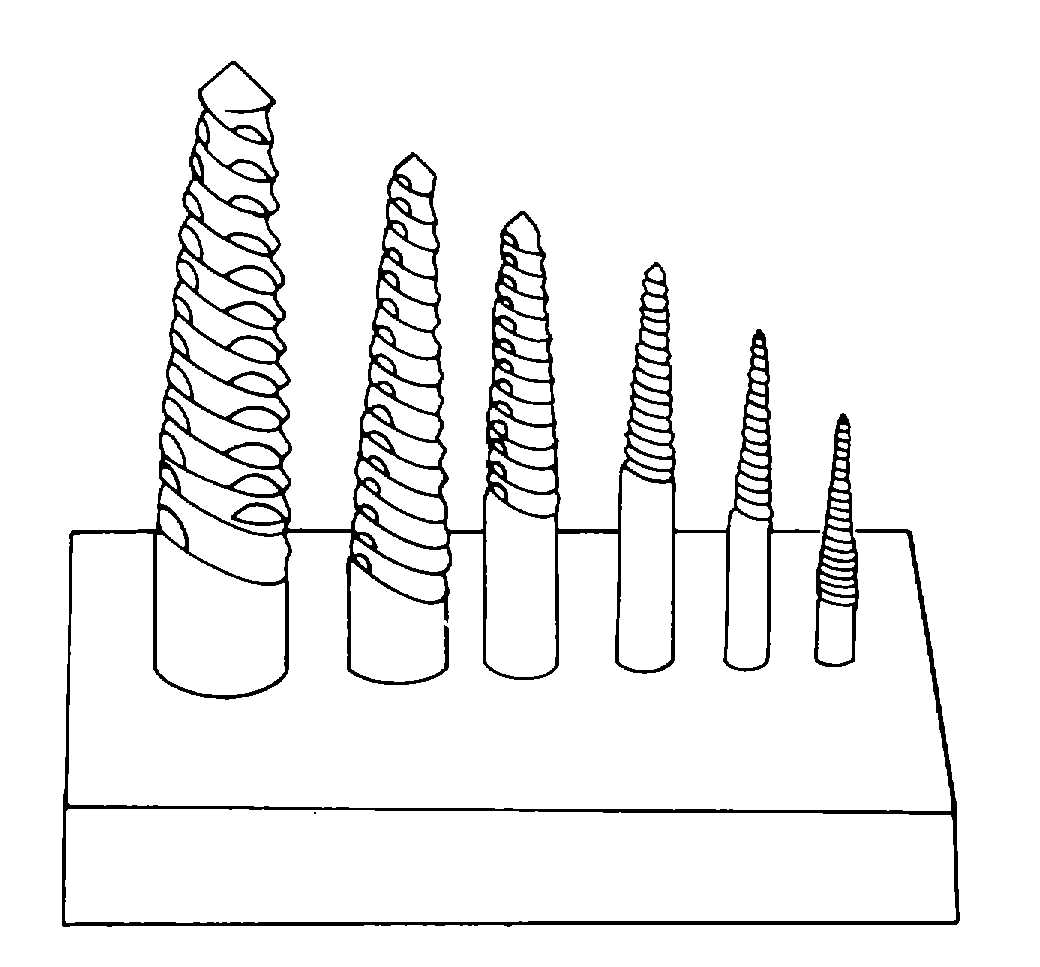

Figure 4-108. Spiral Screw Extractors

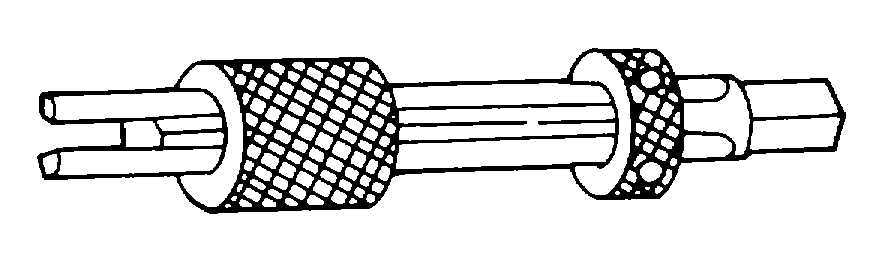

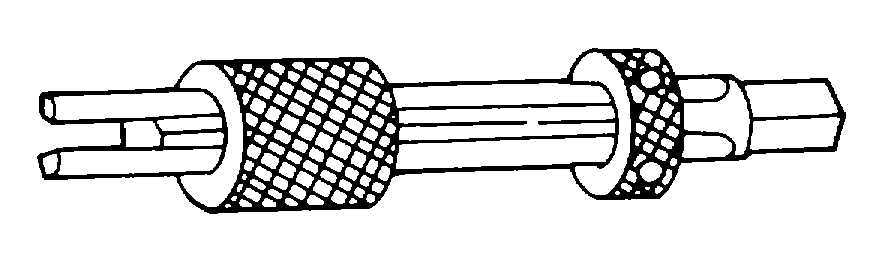

Figure 4-109. Tap Extractor

NOTE

Screws and taps can be removed with the

spiral screw extractor.

(1)

Spiral extractor. To remove a broken screw or

tap with a spiral extractor, proceed as follows:

WARNING

Always wear eye protection when drilling.

Failure to comply may result in serious

injury to personnel.

(a)

Center punch and drill a hole of the proper

size in the screw or tap. Use a drill size guide if

available. If one is not available, drill the hole slightly

smaller than the diameter of the extractor.

NOTE

Some extractors have the required drill size

stamped on them.

(b)

Insert the extractor into the drilled hole.

(c)

Place a tap wrench or an open-end

wrench on the extractor.

(d)

Remove the broken screw by turning the

extractor counterclockwise.

(2)

Tap extractor. If a tap has broken off at or

slightly below the surface of the work, proceed as

follows:

(a)

Apply a liberal amount of penetrating oil,

Federal Specification VV-P-216, to the broken tap.

(b)

Place the tap extractor over the broken

tap and lower the upper collar to insert the four sliding

prongs down into the four flutes of the tap, as shown in

figure 4-110.

4-44