TM 1-1500-204-23-9

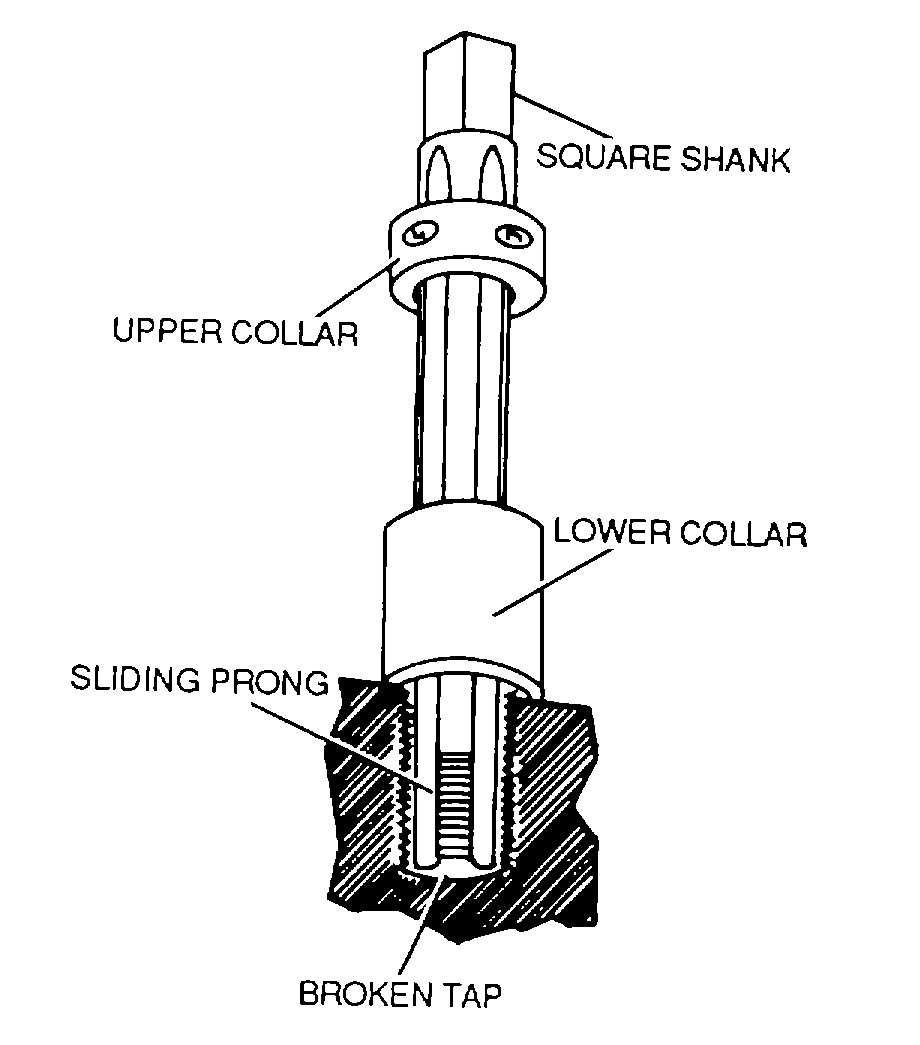

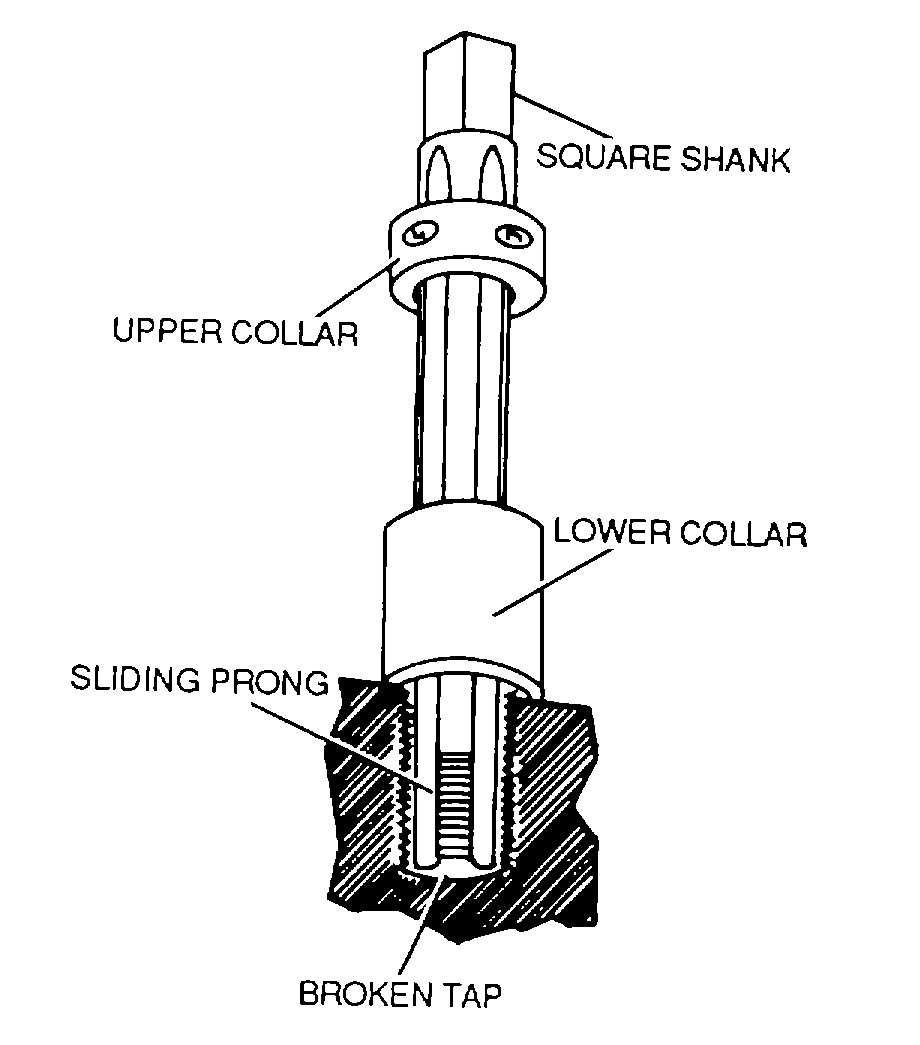

Figure 4-110. Use of Tap Extractor

(c)

Slide the bottom collar down to the

surface of the work so that it will hold the prongs tightly

against the body of the extractor.

(d)

Apply a tap wrench to the square shank

and tighten.

(e)

Loosen the tap by carefully working the

extractor back and forth.

NOTE

It may be necessary to remove the

extractor and strike a few sharp blows

with a small hammer and a pin punch to

jar the tap loose. Then reinsert the

extractor and carefully try to back the tap

out of the hole.

c.

Care. Observe the following practices for the

care and upkeep of screw and tap extractors:

(1)

Apply a light coat of oil to prevent rust.

(2)

Wipe excess oil and metal shavings from

extractors.

(3)

Store in the case provided or wrap

individually to protect the cutting edges.

4-21.

Double Cutting Shears. Double cutting shears

have a pointed lower blade which works into a slotted

upper jaw and is used for cutting light gauge pipes,

stacks, cylinders, and square ducts of sheet metal.

Most of these shears are equipped with a crimping

attachment on one side for crimping the ends of piping

or ducting when fitting several sections together. A

small strip is sheared away when a cut is made with

these shears. Maintenance for double cutting shears is

the same as that prescribed for snips.

WARNING

Cutting and nipping metal items may cause pieces of

metal to be thrown. Wear protective eye wear and

gloves.

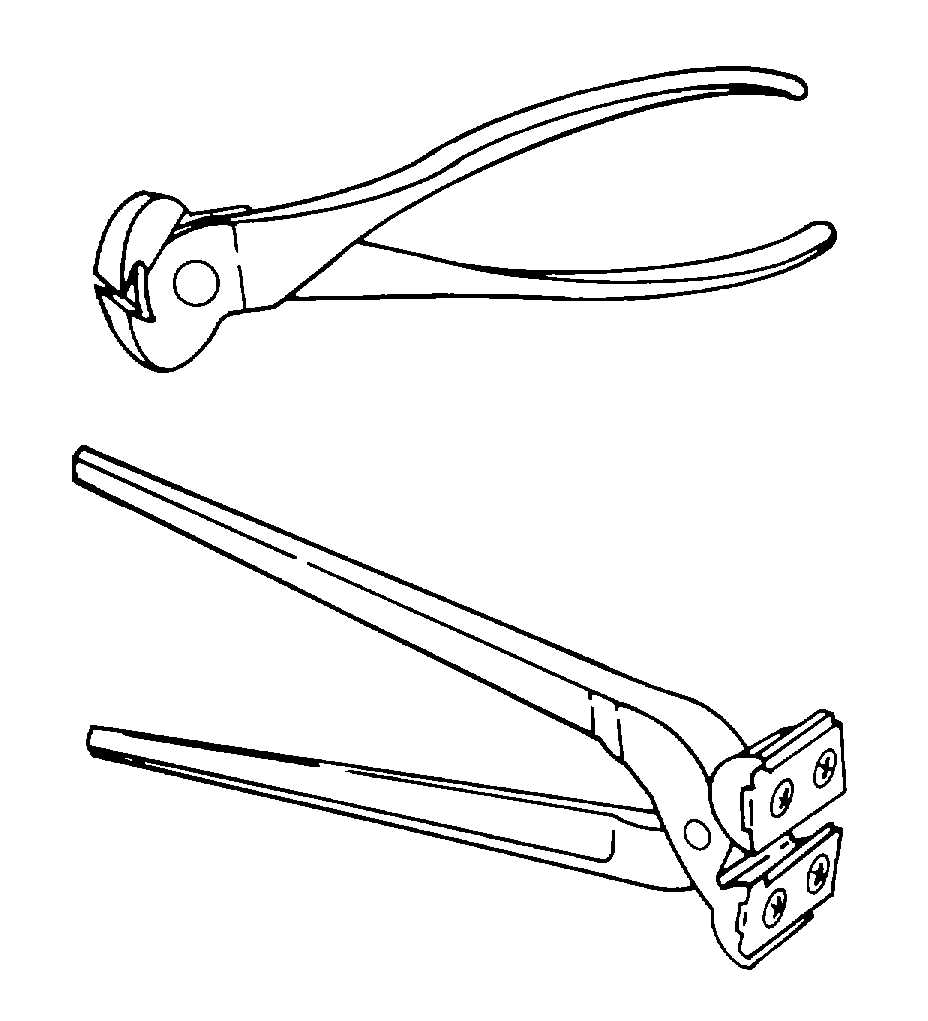

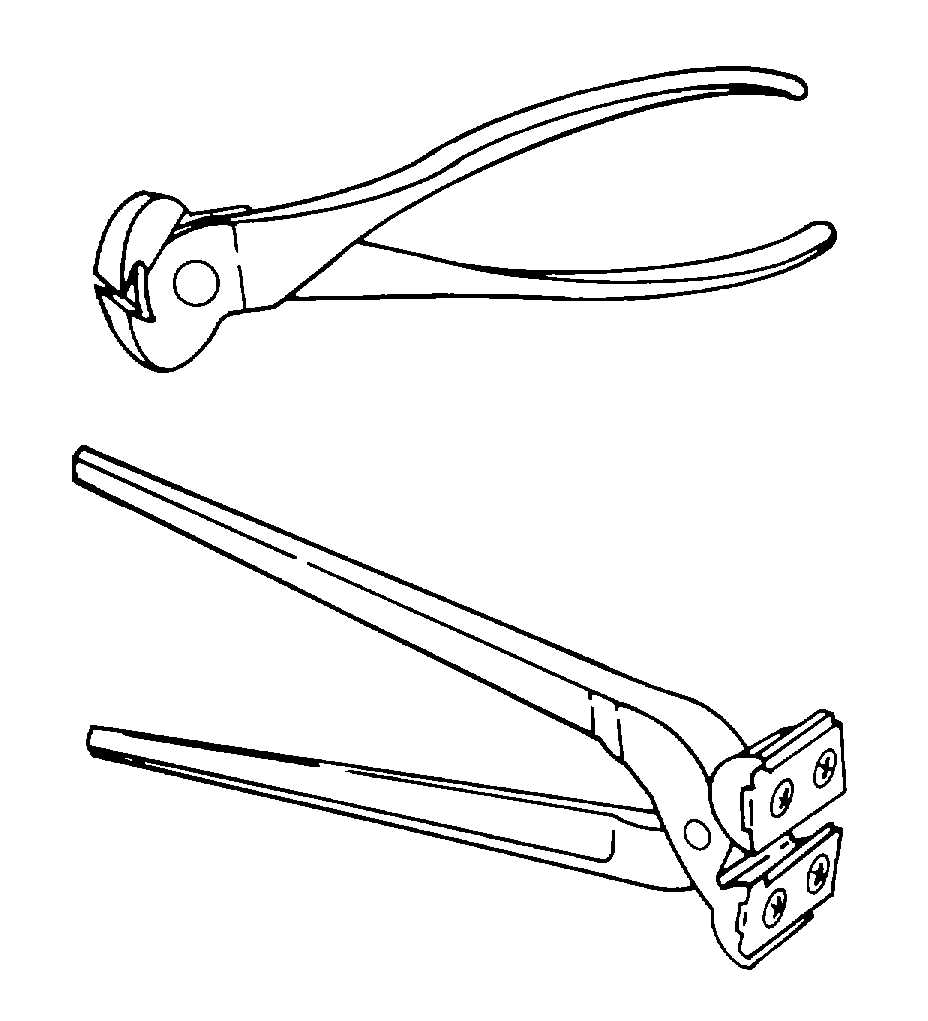

4-22. Nippers and Pincers. Nippers are used to cut

protruding metal flush with a surface. They are also

used to cut wire, bolts, nails, and light metal bars to

specified dimensions. Nippers come in a variety of

styles and sizes. Figure 4-111 shows typical tools of this

type.

a.

Use. Nippers and pincers, as previously stated,

are used to cut wire, bolts, rivets, nails, and other similar

items. Figure 4-112 illustrates the technique for cutting

wire, and figure 4-113 shows the procedure for cutting a

rivet or similar object flush with the surface.

Figure 4-111. Nippers and Pincers

4-45