TM 1-1500-204-23-9

CHAPTER 3

MEASURING TOOLS

3-1. General. In the maintenance of Army aircraft, the

fabrication of many parts may be required. During this

process, accurate measurements must be made before

and during the fabrication procedure. A partly finished or

a finished part must also be checked for accuracy. This

inspection includes comparing the dimensions of the

workplace with the required dimensions shown on a

drawing or sketch. These measurements are made using

a variety of measuring tools. The accuracy of the

measurements will depend upon the types of tools used

and the ability of the aircraft repairer to use them

correctly.

3-2. Levels. Levels are tools designed to prove whether

a plane or surface is in the true vertical or true horizontal.

All levels consist of a liquid-filled glass tube or tubes

supported in a frame.

a. Types. There are many types of levels used in

aircraft maintenance. Some of these are described

below.

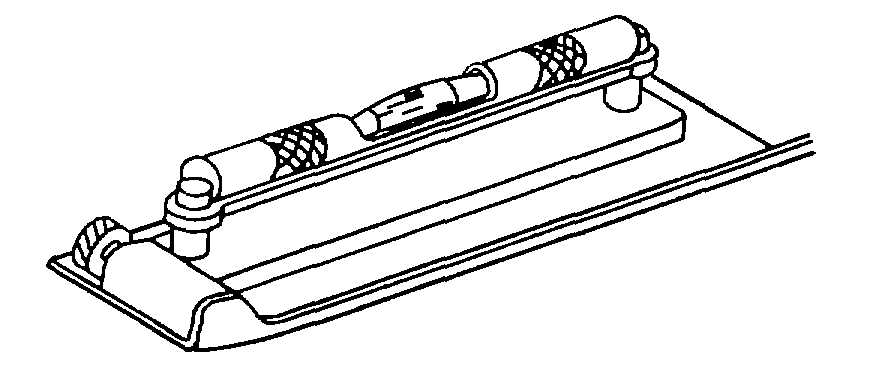

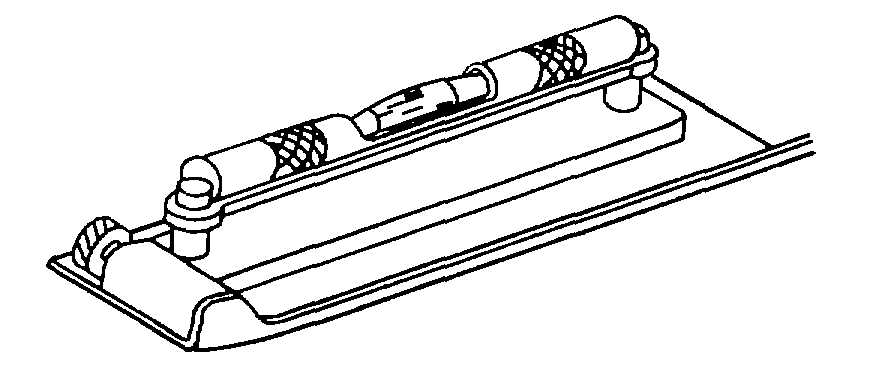

(1) Master precision level.

The

master

precision level, shown in figure 3-1, has a ground and

graduated main vial. The top and bottom of the level are

milled and ground to make sure both surfaces are

absolutely parallel. This level is used to determine the

true horizontal with the main vial. The true vertical is

determined by using the two smaller vials.

Figure 3-1. Master Precision Level

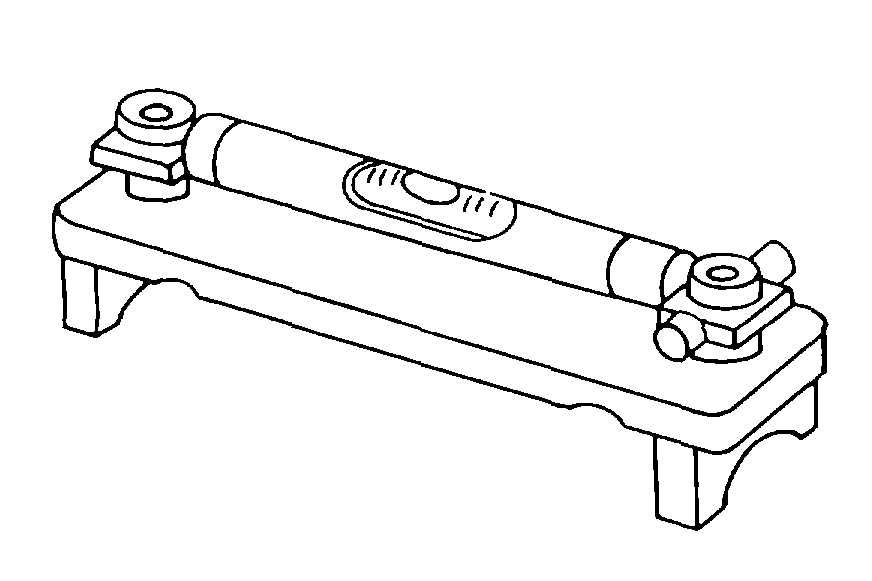

(2)

Machinist's level.

The machinist's level,

shown in figure 3-2, has an extra large vial. This

increases its accuracy and sensitivity. Some of these

levels have grooved bottoms which fit over pipes and

shafts. They are used in machine shops for leveling work

and equipment.

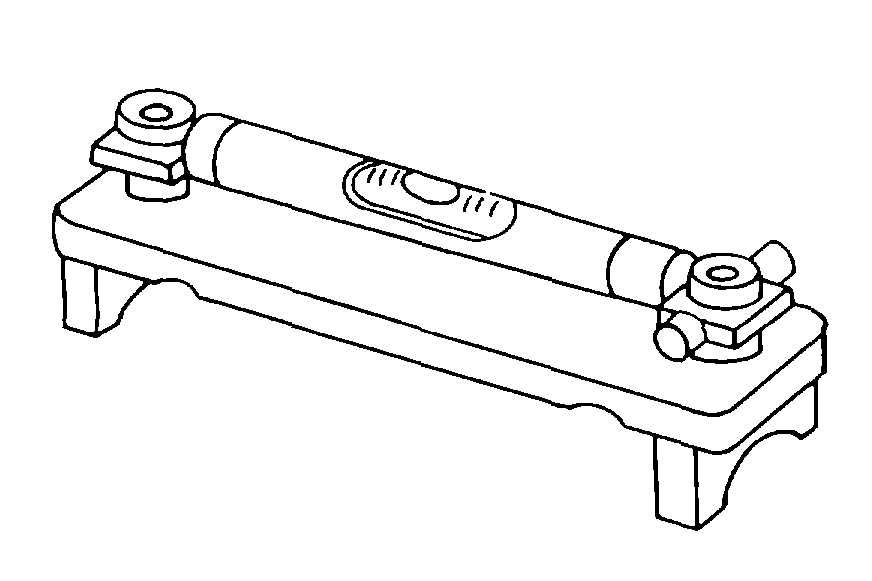

(3)

Striding level. The striding level is a

machinist's level which is mounted on a raised base. This

level, shown in figure 3-3, is used to span existing

cabling, piping, or similar obstructions. It is extremely

useful in a machine shop for checking the true horizontal

of the flatway on a lathe.

Figure 3-2. Machinist's Level

Figure 3-3. Striding Level

3-1