TM 1-1500-204-23-9

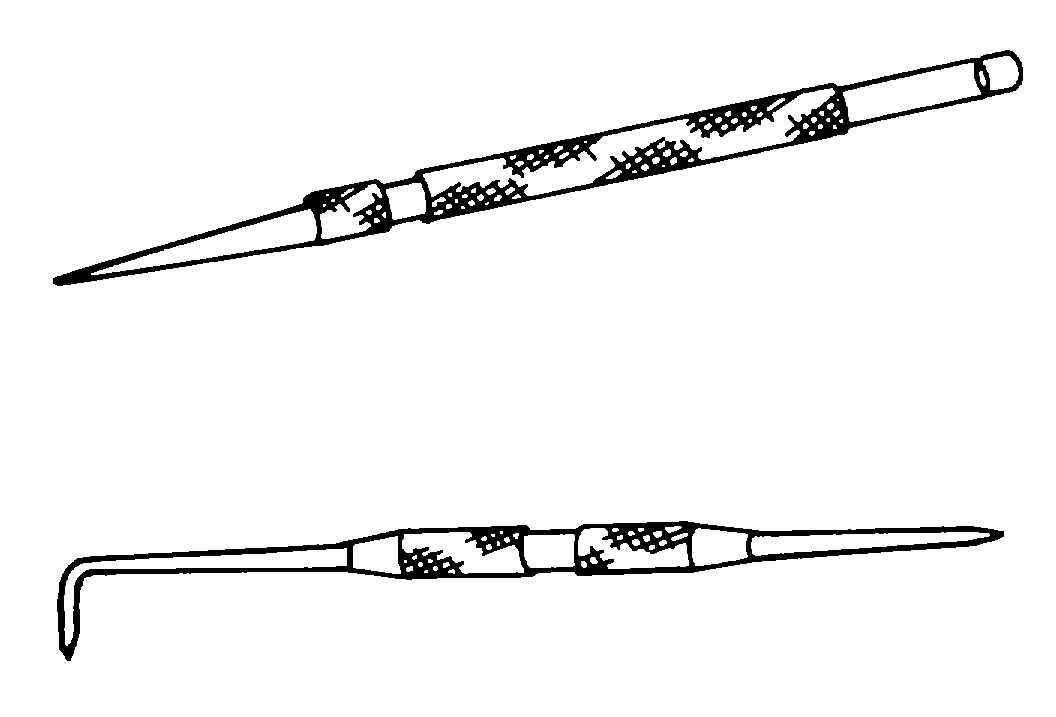

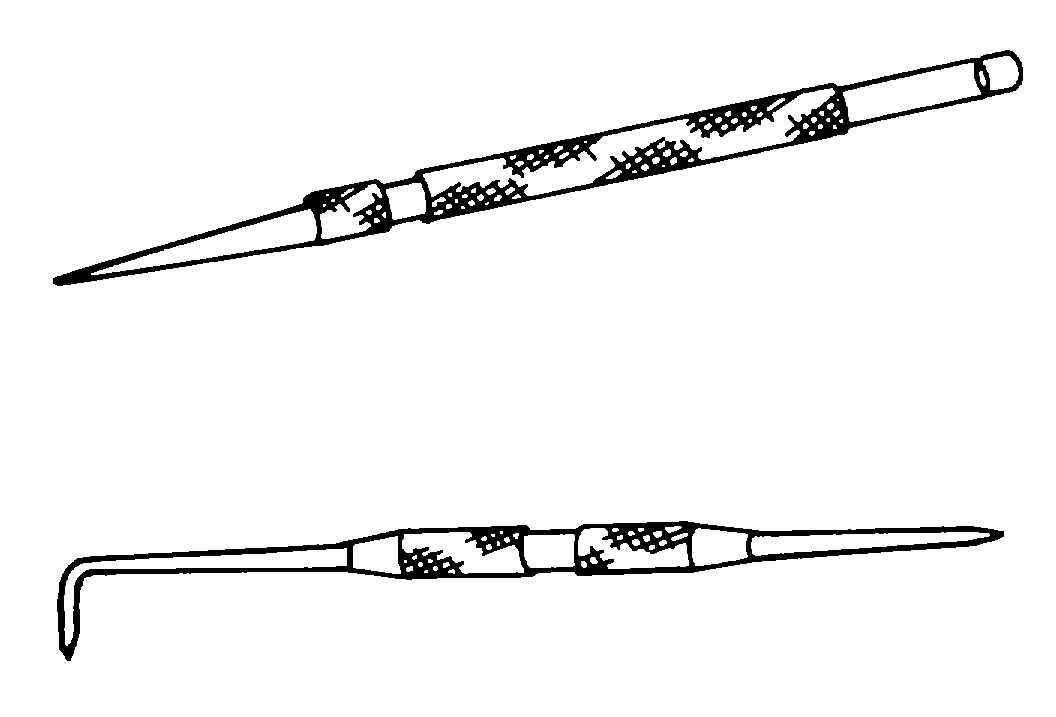

Figure 3-7. Mechanist's Scribers

(2) Tungsten carbide. Tungsten carbide tips

have extremely hard points and are used on hardened

steel or glass.

b. Use. Following is the basic procedure for the

use of a scriber:

(1) Place material to be marked on a firm

surface. Place a steel rule or straight edge on the work

beside the line to be scribed.

(2) Use fingertips of one hand to hold the

straight edge securely. Hold the scriber in your hand as

you would a pencil.

(3) Scribe the line by drawing the scriber along

the straight edge at a 45-degree angle and tipped in the

direction it is being moved.

c. Care. Observe the following practices for the

care of scribers:

(1) Protect points by reversing them in the

handle or placing a cork or a piece of soft wood over

point.

(2) Keep the scribers clean and lightly oiled.

(3) Stow on a rack or in a box. TM 1-1500-204-

23-9

(4) Do not use scribers for other than intended

purposes.

d. Repair. Scribers can only be repaired by

sharpening. Sharpen scriber points with a small oil

stone, Federal Specification SS-S-736, moistened with

lubrication oil.

3-5. Tapes and Rules. Tapes and rules are the

measuring instruments most often used for all general

measurements. They are graduated into fractions of an

inch that may be expressed as 1/2, 1/4, 1/8, 1/16, 1/32,

and 1/64.

a. Tapes. There are several kinds and lengths of

tapes, but the one most often used is 6 feet long and

made of flexible steel. It is coiled in a circular case and

may or may not have one end fastened permanently to

the case. It is graduated on one side only in 1/16 and

1/32 inch divisions. A small lip on the end prevents the

tape from sliding completely inside the case and also

easily lines up the end of the tape with the end of a

piece of stock. Examples of typical tapes are shown in

figure 3-8.

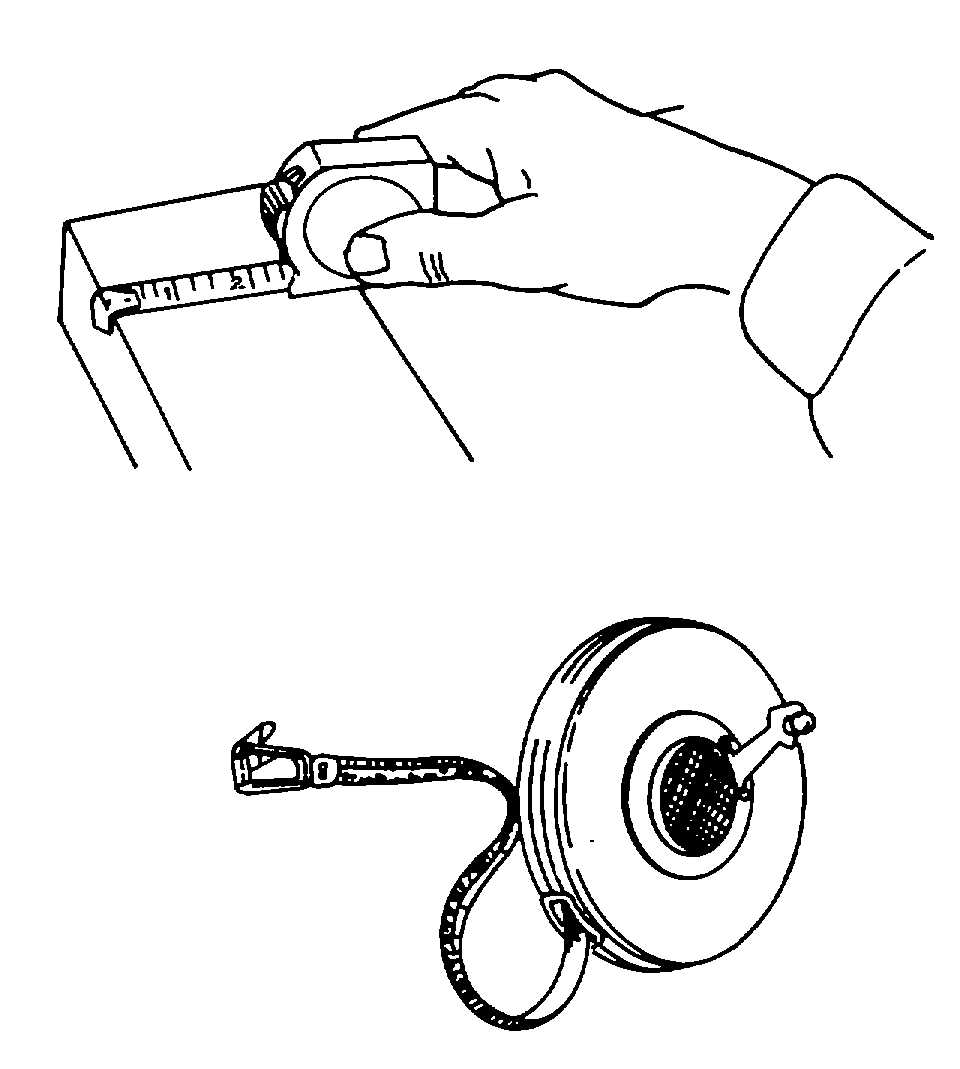

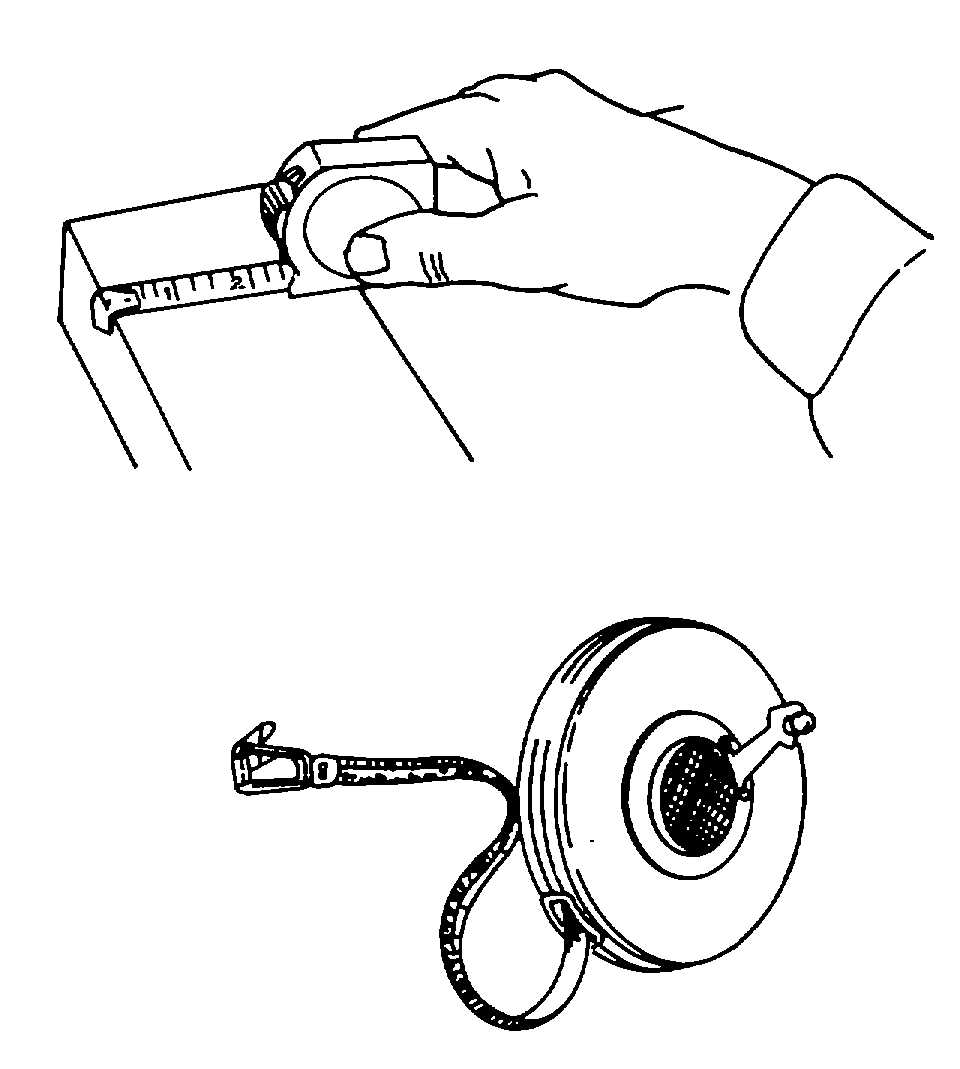

Figure 3-8. Typical Tapes

3-3