TM 1-1500-204-23-9

(6) Conversion for inside measurement. If the

metric caliper is not marked for inside or outside

measurements, refer to (4) above for the measuring

point allowance for inside measurements.

d. Care of Calipers. Following are general

guidelines for the care of all calipers:

(1) Coat metal parts of all calipers with a light

coat of oil to prevent rust.

(2) Store calipers in separate containers

provided.

(3) Keep graduations and markings on all

calipers clean and legible.

(4) Do not drop any caliper. Small nicks or

scratches can cause inaccurate measurements.

(5) Protect caliper points from damage.

3-9. Micrometers. The micrometer is the most

accurate of the adjustable measuring instruments. The

internal parts of a micrometer are not cut on a lathe, but

are ground to size on a machine grinder.

a. Types. There are three types of micrometers

which

are

most

commonly

used:

the

outside

micrometer; the inside micrometer; and the depth

micrometer.

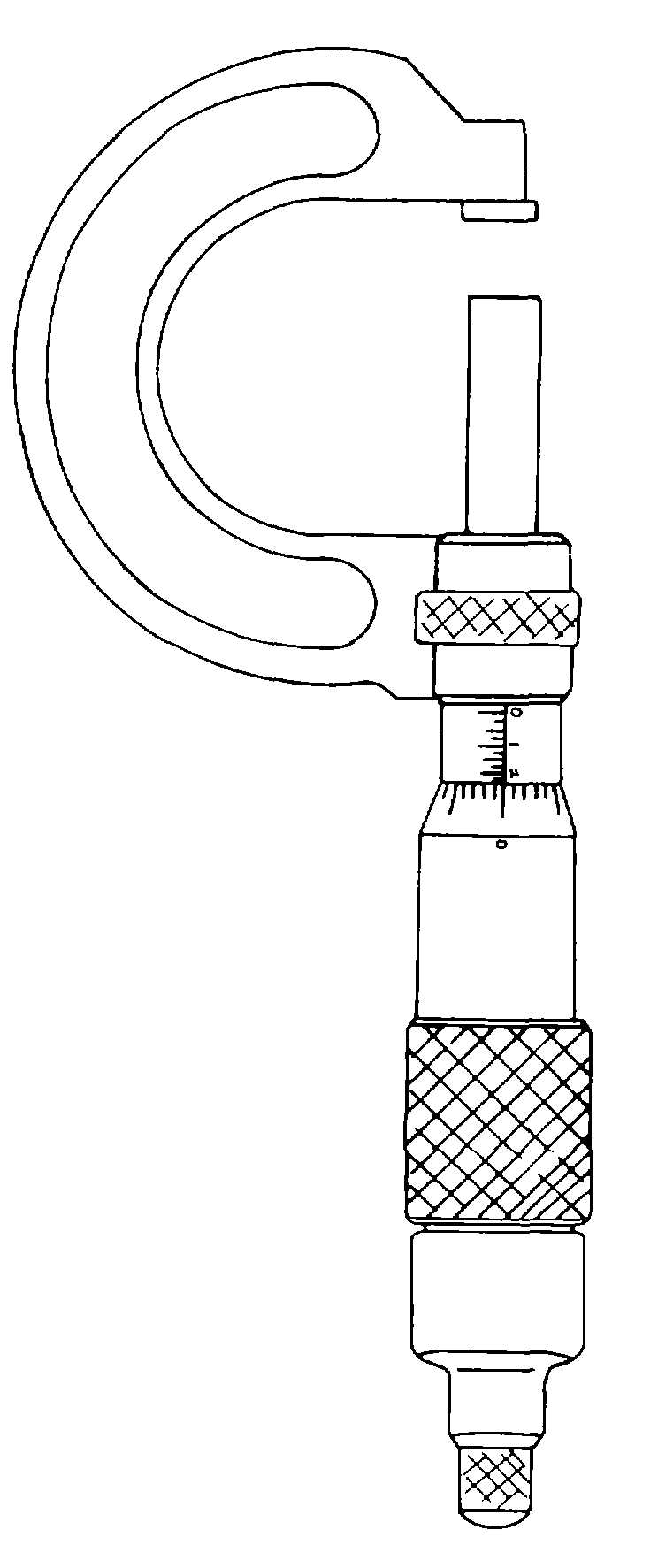

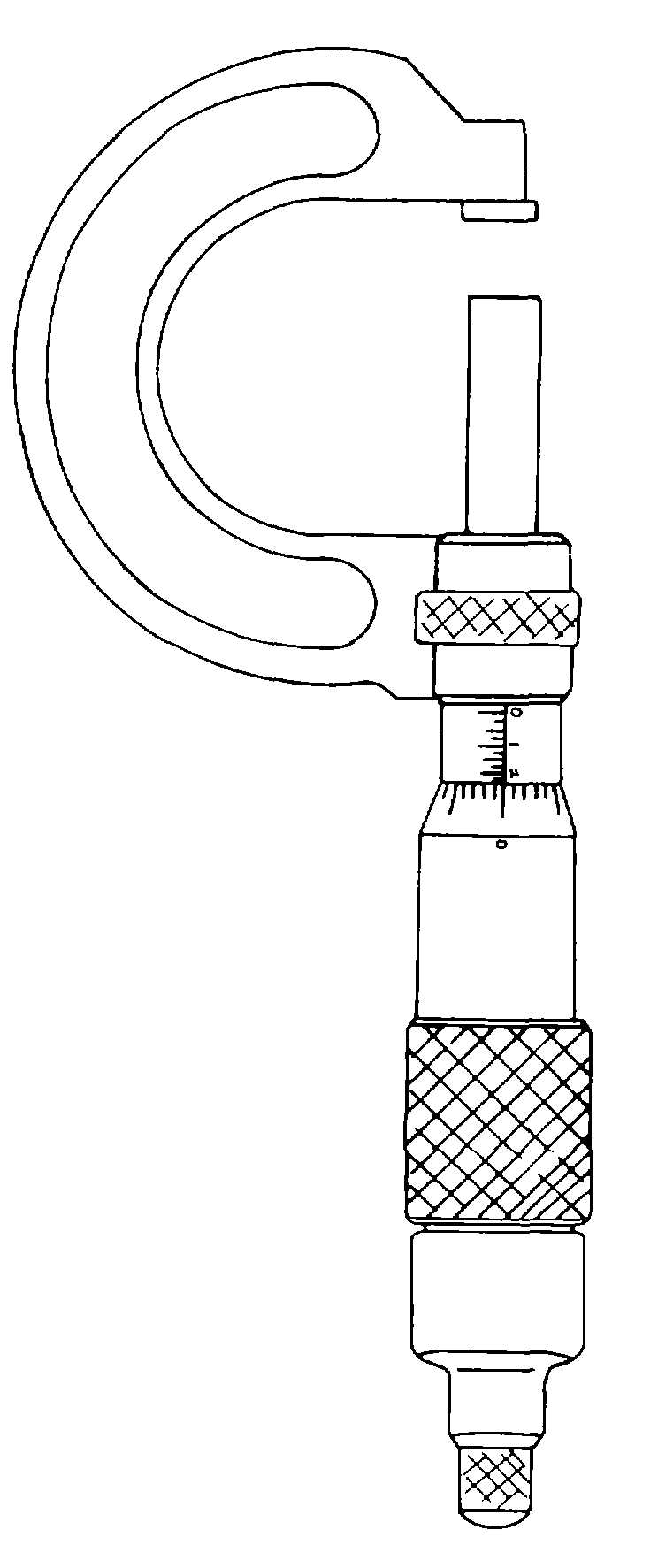

(1)

Outside

micrometer.

An

outside

micrometer, shown in figure 3-34, is used more often

than any other type. It is used to measure the outside

diameter of shafts, thickness of stock, and to make

other, similar measurements. It is also used to set

inside calipers to a given dimension.

(2) Inside micrometer. An inside micrometer is

used to measure the inside diameters of cylinders, the

width of recesses, and similar work. A typical inside

micrometer is shown in figure 3-35.

(3) Depth micrometer. A depth micrometer,

shown in figure 3-36, is used to measure the depth of

recesses or holes.

b. Selection. The types of micrometers commonly

used are made so that the longest movement possible

between the spindle and the anvil is 1 inch. This

movement is called the range. The size of a

micrometer indicates the size of the largest work it will

measure. Therefore, a 2-inch micrometer has a range

from 1 inch to 2 inches, and will measure only work

between 1 and 2 inches thick. A 6-inch micrometer has

a range from 5 to 6 inches, and will measure only work

between 5 and 6 inches thick. It is necessary, therefore,

that the mechanic first find the approximate size of the

work to the nearest inch, and then select a micrometer

that will fit it. With inside and depth micrometers, rods

of suitable lengths, as shown in figure 3-37, are fitted

into the tool to get the approximate dimension within an

inch, after which the exact dimension is obtained by

turning the thimble, as shown in figure 3-38.

Figure 3-34. Outside Micrometer

3-14