TM 1-1500-204-23-9

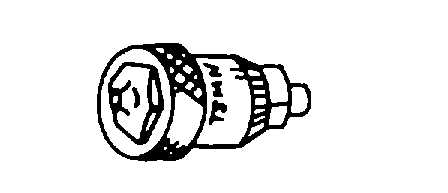

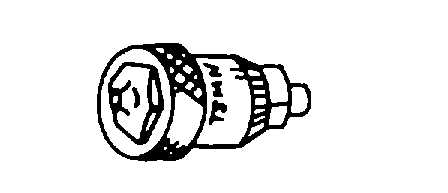

Figure 3-35. Inside Micrometer

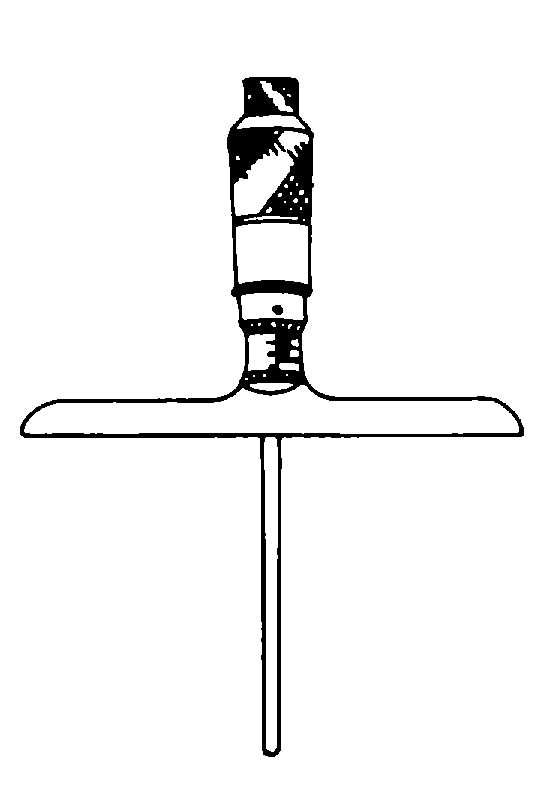

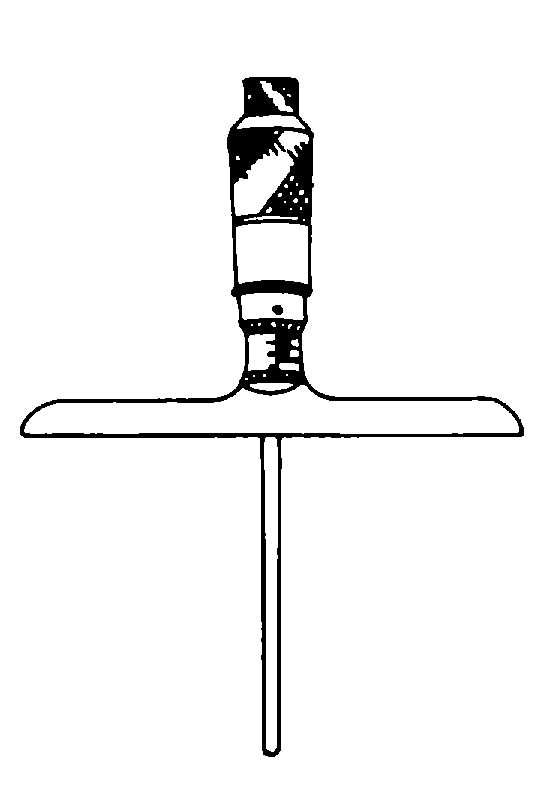

Figure 3-36. Depth Micrometer

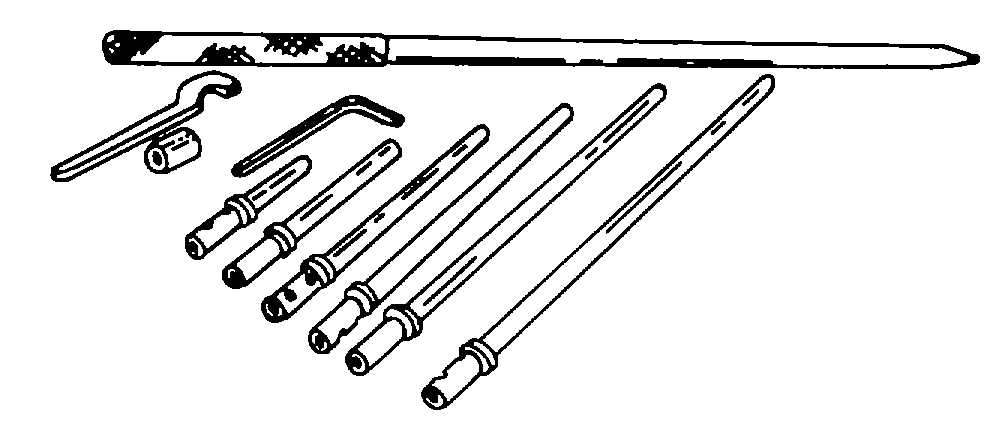

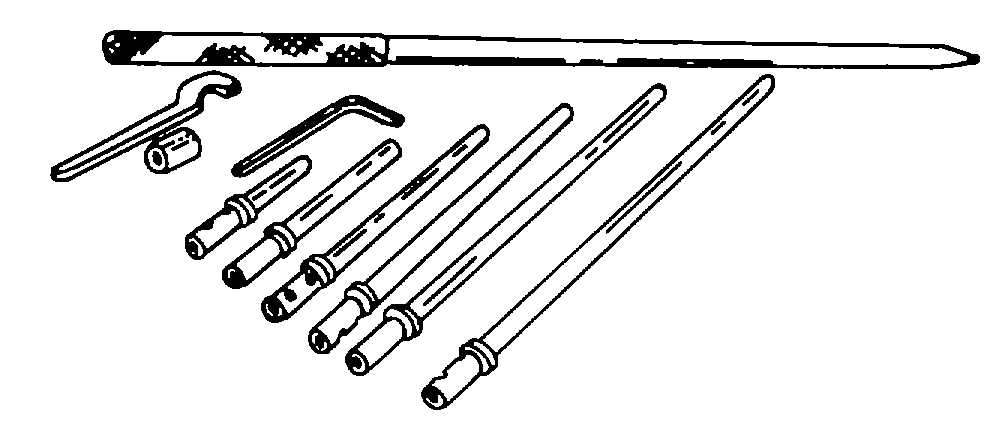

Figure 3-37. Extension Rods for Inside and

Depth Micrometers

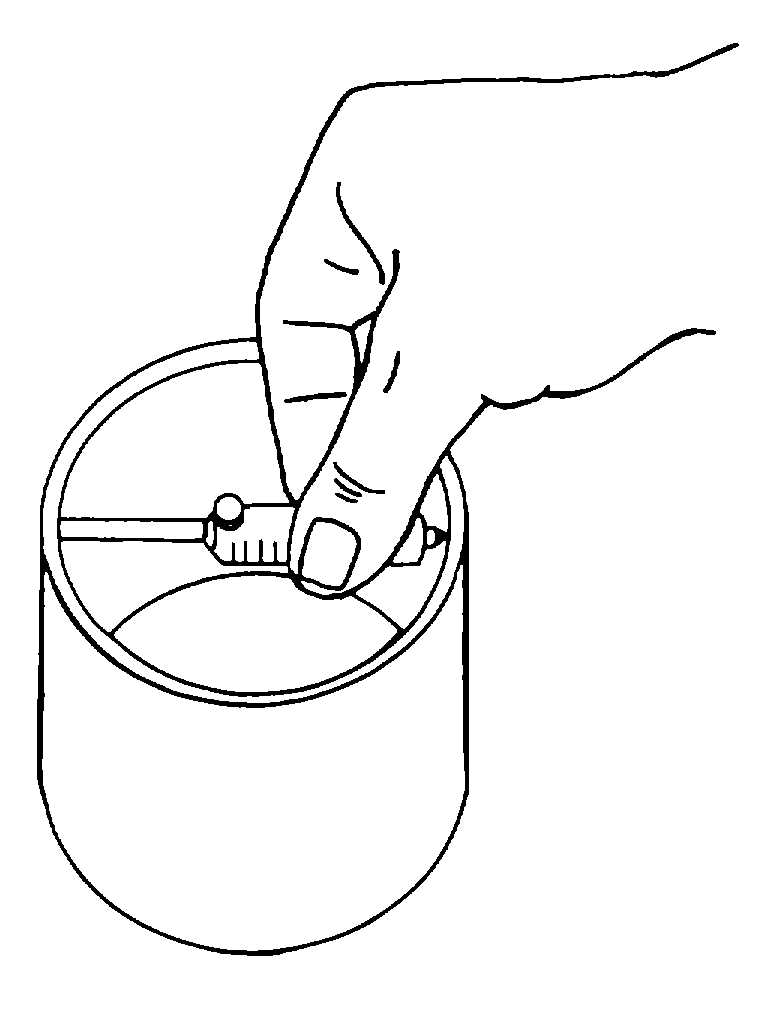

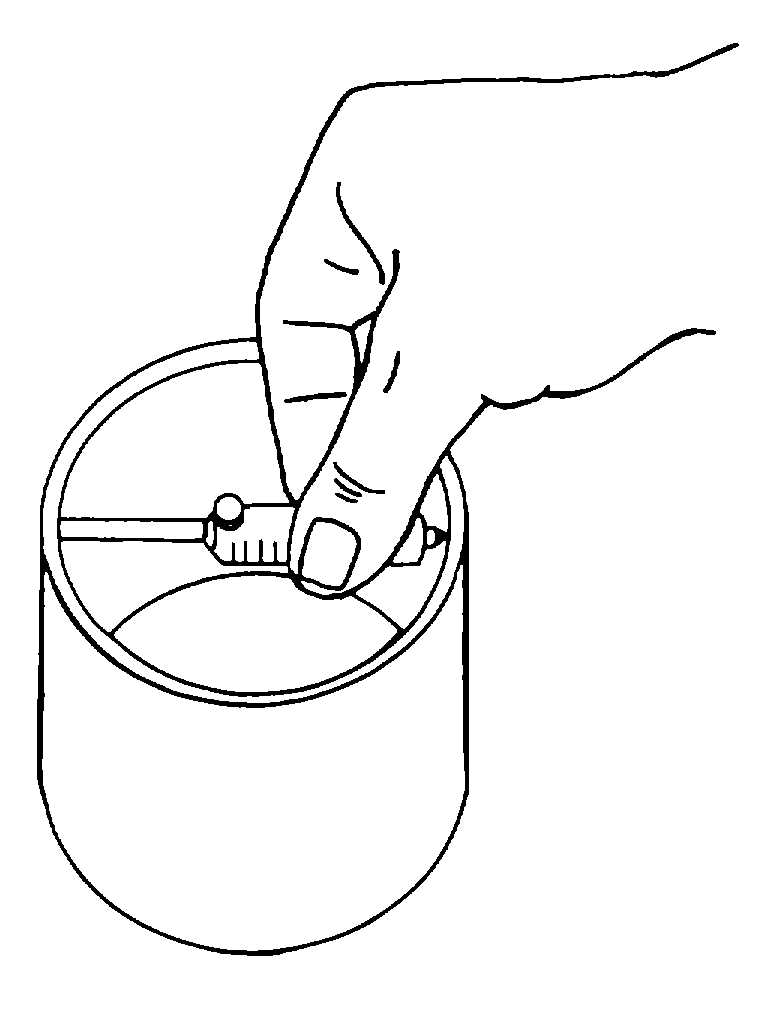

Figure 3-38. Using Inside Micrometer

c. Use. The following paragraphs discuss the basic

use of the outside and inside micrometers.

(1) Outside micrometer. As shown in figure 3-

39, the micrometer is held in one hand and the stock in

the other. The thimble is turned until the anvil and

spindle just touch the stock. The micrometer is then

read for an accurate measurement.

(2) Inside micrometer. The normal procedure in

using an inside micrometer is to set it across a diameter

or between the inside surfaces, remove it, and then read

the dimension. For this reason, the thimble on an inside

micrometer is much stiffer than on a micrometer caliper

it holds the dimension well. It is good practice to verify

the reading of an inside micrometer by measuring it with

a micrometer caliper.

(a) Technique. Figure 3-40 shows an inside

micrometer with extension rod being used to check the

diameter of a bored hole. Note the arrows which

indicate the direction the operator is feeling for the

largest

dimension

horizontally

and

the

smallest

dimension vertically. Inside micrometers have spherical

contact points which require more practice to feel the

full measurement of the diameter. One contact point is

generally held in a fixed position and the other rocked in

different directions to

3-15