TM 1-1500-204-23-9

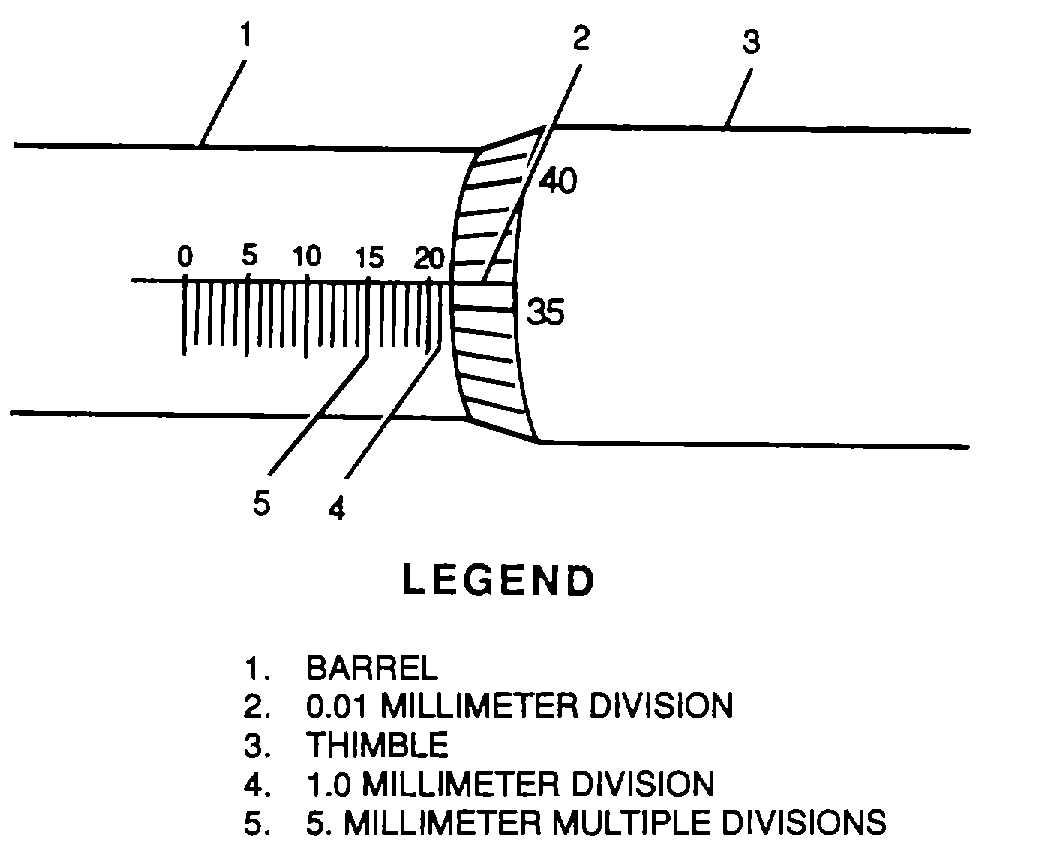

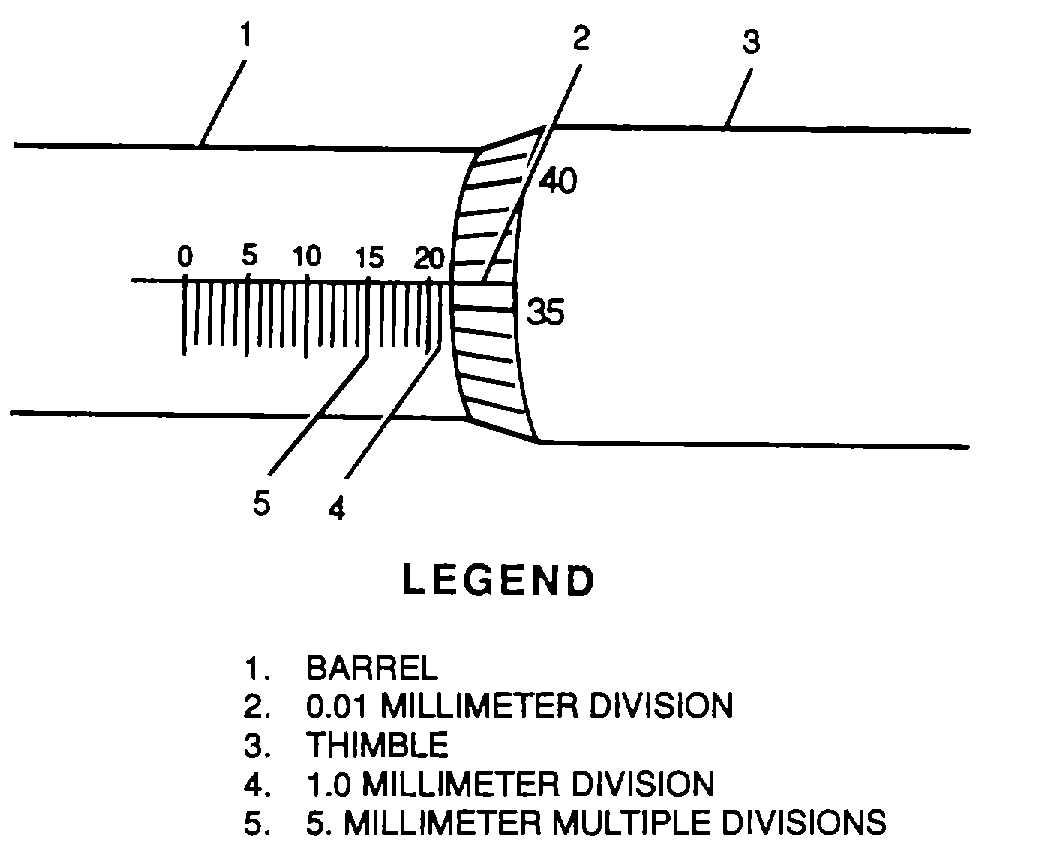

Figure 3-44. Reading a Metric Micrometer

(3) Thimble graduations. The thimble (3) is

graduated in 50 divisions with every fifth line being

numbered. Each line represents a distance of 1/100, or

0.01 mm.

(4) Reading a measurement. A measurement

can be read as follows:

Read the highest whole number visible on the

barrel (5) and record ................. 20 = 20.0 mm

Count the number of lines visible between the

20 and the thimble edge (4) and record 2 = 2.0 mm

Locate the line on the thimble (3) that coincides

with or has passed the horizontal line in the

barrel (2) and record ..... 36 = 36/100 = 0.36 mm

Total all preceding measurements ..... 22.36 mm

The measurement, therefore, is 22.36 millimeters.

g. Transferring Measurements from Inside Caliper

or Inside Micrometer to Micrometer Caliper. When it

becomes necessary to transfer a measurement from an

inside caliper to an outside caliper, perform the following

procedures: TM 1-1500-204-23-9

(1) After setting inside caliper or inside

micrometer to the work, hold the micrometer caliper in

one hand and the inside tool in the other hand.

(2) Turn the thimble of the micrometer caliper

with the thumb and forefinger until the inside tool legs

lightly contact the anvil and spindle of the micrometer

caliper.

(3) Hold the tips of the inside tool legs parallel

to the axis of the micrometer caliper spindle.

(4) The micrometer caliper will be accurately

set when the inside tool will just pass between the anvil

and spindle by its own weight.

h. Micrometer Adjustment and Testing. At times it

may become necessary to adjust and/or test the

accuracy of a micrometer.

(1) Adjustment. Micrometer may be adjusted to

compensate for thread wear. Adjust as follows.

(a) Unscrew thimble from barrel.

(b) Tighten the thread play adjustment nut

on the fixed nut a fraction of a turn at a time.

(c) Test the fit of the micrometer screw in

the fixed nut.

(d) Repeat the tightening and test in the

fixed nut until the operation is free from binding and

play.

(2) Testing. A micrometer is tested for

accuracy as follows:

(a) Clean the measuring faces with a soft

cloth and examine the faces for any lint left by the cloth.

(b) Measure the length of the micrometer

test gauge of the same length as the minimum capacity

of the micrometer.

(c) The micrometer should read the exact

measurement.

(d) For the 1-inch micrometer, screw the

thimble down until the spindle contacts the anvil. The

reading should be 0.000 inch.

3-19