TM 1-1500-204-23-9

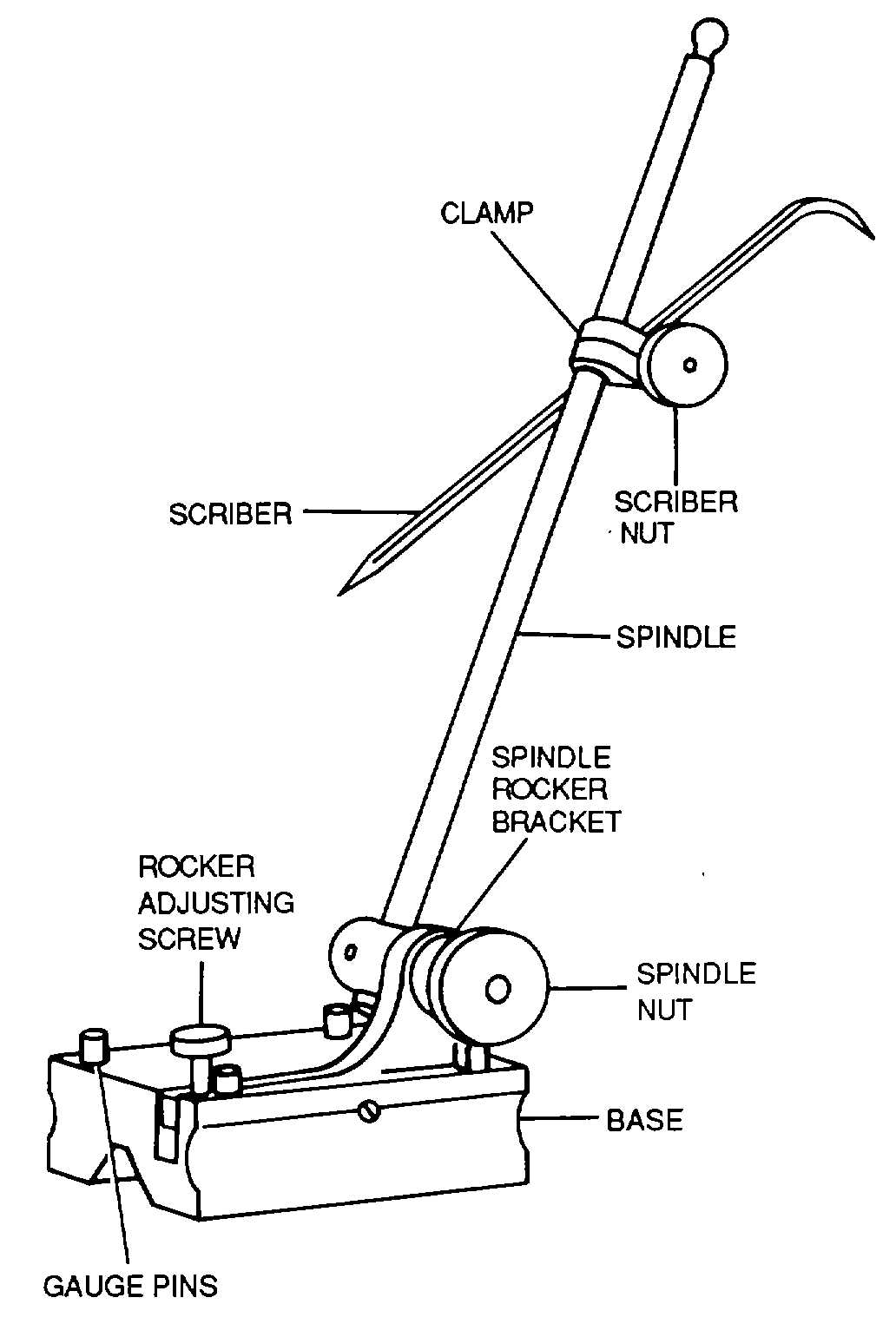

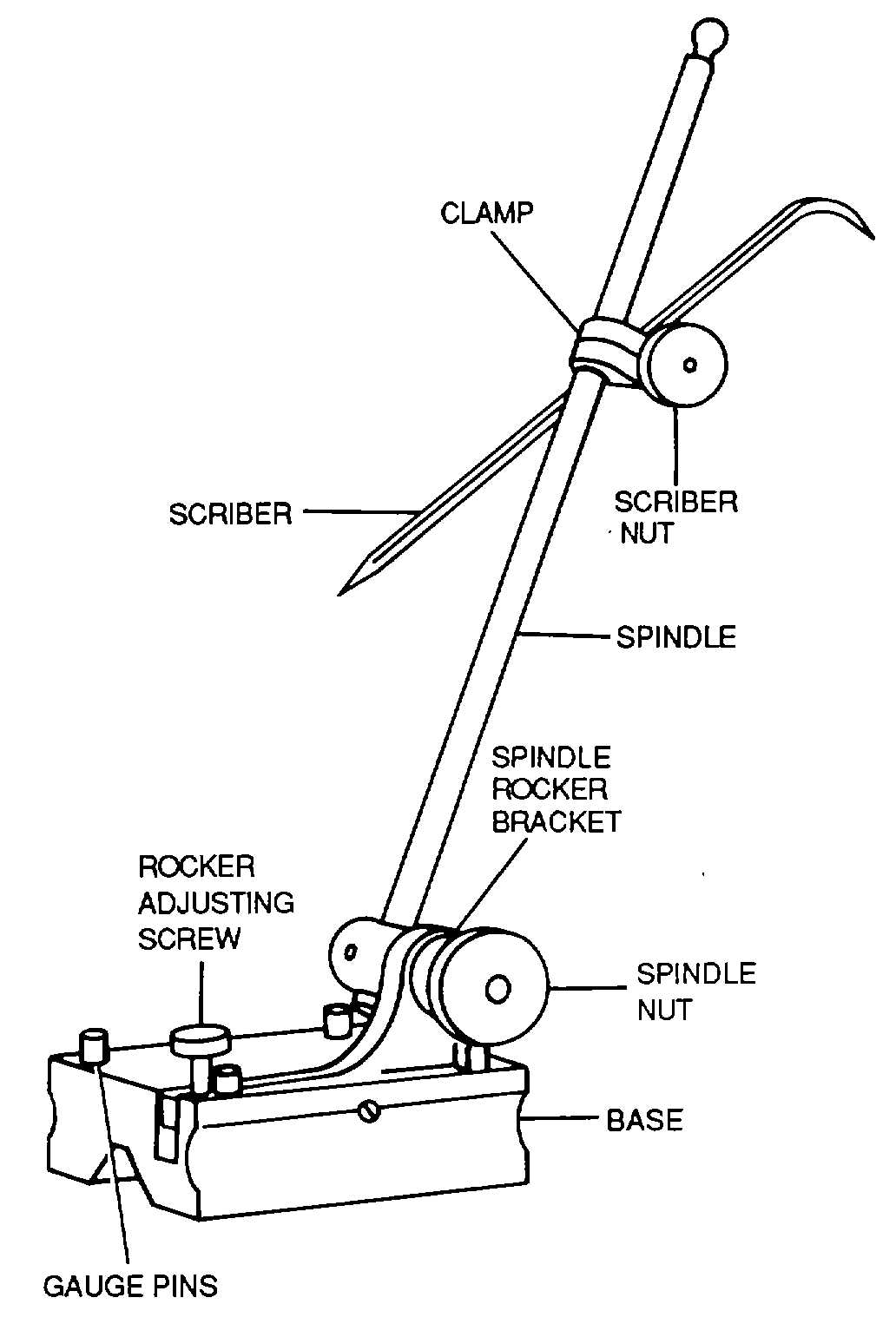

Figure 3-45. Surface Gauge

(1) Rule depth gauge. The rule depth gauge,

shown in figure 3-47, is a graduated rule with a sliding

head designed to bridge a hole or slot, and hold the rule

perpendicular

to

the

surface

from

which

the

measurement is taken. This type has a measuring

range from 0 to 5 inches. The sliding head has a

clamping screw so that it may be clamped in any

position. The sliding head is flat and perpendicular to

the axis of the rule and ranges in size from 2 to 2 5/8

inches wide and from 1/8 to 1/4 inch thick.

(2) Micrometer depth gauge. The micrometer

depth gauge, shown in figure 3-48, consists of a flat

base attached to the barrel of a micrometer head.

These gauges have a range from 0 to 9 inches,

depending on the length of extension rod used. The

hollow micrometer screw itself has a range of either 1/2

or 1 inch. Some are provided with a ratchet stop. The

flat base ranges in size from 2 to 6 inches. Several

extension rods are normally supplied with this type of

gauge.

(3) Vernier depth gauge. The vernier depth

gauge, shown in figure 3-49, consists of a graduated

scale, either 6 or 12 inches long, and a sliding head

similar to the one on the vernier caliper. The sliding

head is especially designed to bridge holes and slots.

The vernier depth gauge has the range of the rule depth

gauge and not quite the accuracy of a micrometer depth

gauge. It cannot enter holes less than 1/4 inch in

diameter, whereas a micrometer depth gauge will enter

a 3/32-inch hole. However, it will enter a 1/32-inch slot,

whereas a micrometer depth gauge will not. The vernier

scale is adjustable and may be adjusted to compensate

for wear.

b. Operation of Depth Gauges. The following

paragraphs describe operating procedures for each of

the depth gauge types described above.

(1) Rule depth gauge. To measure the depth of

a hole or slot with reasonable accuracy, proceed as

follows:

3-21