NAVAIR 01-1A-505-2

004 02

TO 00-25-255-1

Page 19

TM 1-1500-323-24-2

c.

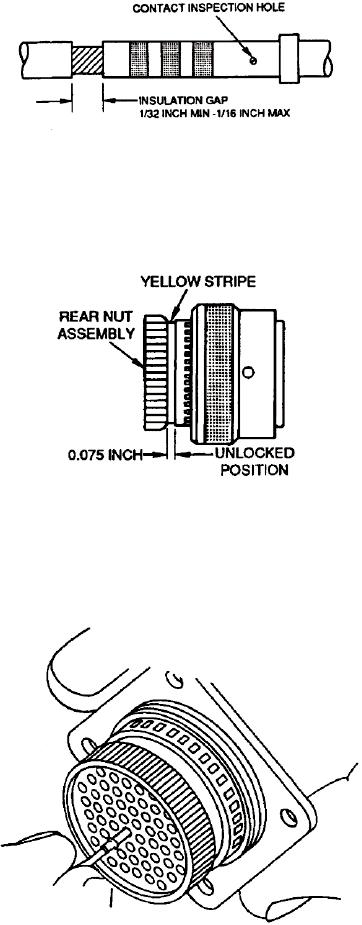

Insert stripped wire into contact conductor

barrel. Ensure all wire strands are inside contact

conductor barrel and visible in contact inspection hole

(Figure 9).

d. If insulation gap is too large, trim conductor

as required. If insulation gap is too small, trim

insulation as required (NAVAIR 01-1A-505-1,

Figure 9. Insulation Gap

WP 009 00)

41. CONTACT CRIMPING.

a. Select crimp tool frame and positioner (Table 5,

6, 8 or 9).

b. Perform die closure check, install positioner,

and set selector knob for gage of wire. Crimp contact

to wire (NAVAIR 01-1A-505-1, WP 013 00).

42. CONTACT INSERTION. The following procedure

covers installation of wired or unwired, power,

thermocouple, and coaxial contacts:

NOTE

Series 1 and 2 connectors are front release type,

and ganged retention. The contacts are inserted

and removed from the rear of the connector.

Figure 10. Unlocking Connector

a. If not previously removed, remove backshell

from rear of connector. Turn rear nut assembly

or 5/64 inch space, minimum). Yellow stripe will be

visible (Figure 10).

b. Remove sealing plug and/or contact from

contact cavity.

c.

Route wire or cable through backshell.

NOTE

Start contact insertion near center contact

cavities and work outward.

d. Hand insert contact into corresponding hole

until only crimp barrel portion of contact extends from

grommet (Figure 11).

e.

Select insertion tool specified in applicable

contact tooling table (Table 5, 6, 8 or 9).

Figure 11. Inserting Contacts into Connector