NAVAIR 01-1A-505-2

004 02

TO 00-25-255-1

Page 20

TM 1-1500-323-24-2

NOTE

Take care not to disturb or dislodge seated

contacts by putting strain on wires or cable

while inserting other contacts.

f.

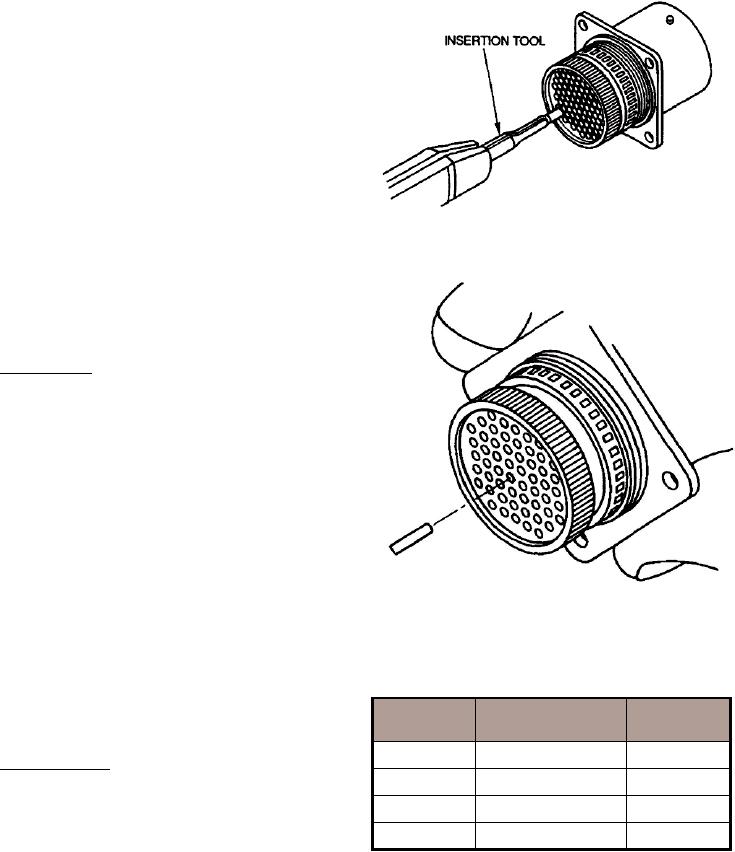

Position insertion tool around rear of contact

(Figure 12). Contact and tool should be aligned within

hole as straight as possible to avoid damage to wire

sealing grommet. Press insertion tool against contact

shoulder firmly to seat contact in cavity.

g. Remove insertion tool by sliding back along

Figure 12. Seating Contact with Insertion Tool

wire insulation until it clears grommet.

h. Seal connector (Paragraph 43), and install

backshell (WP 004 03),

43. CONNECTOR SEALING.

44. Sealing Plugs.

a. Fill all unused cavities with un-crimped

contacts and sealing plugs.

NOTE

All MIL-C-81511 connectors use a straight

sealing plug, without a knob at the end

(Figure 13).

b. Select sealing plug according to size of contact

(Table 10).

Figure 13. Sealing Plug Insertion

c.

Insert sealing plug until bottomed in contact

cavity (Figure 13). Fill all cavities that have un-crimped

contacts. NAVAIR 01-1A-505-1, WP 026 00.

Table 10. Sealing Plug Selection

d. After all contacts and sealing plugs are

inserted, rotate rear nut assembly by hand until nut is

Sealing Plug

Contact Size

Color

fully bottomed against rear shell (Figure 14).

Part Number

12

M81511/15-12

Yellow

45. Moisture Barrier. For connector sealing procedures,

refer to NAVAIR 01-1A-505-1, WP 025 00.

16

M81511/15-16

Blue

20

M81511/15-20

Red

46. CONTACT REMOVAL. Contacts requiring

removal from connectors may be wired, unwired, or

22

M81511/15-22

White

attached to broken wires.