NAVAIR 01-1A-505-2

005 02

TO 00-25-255-1

Page 31

TM 1-1500-323-24-2

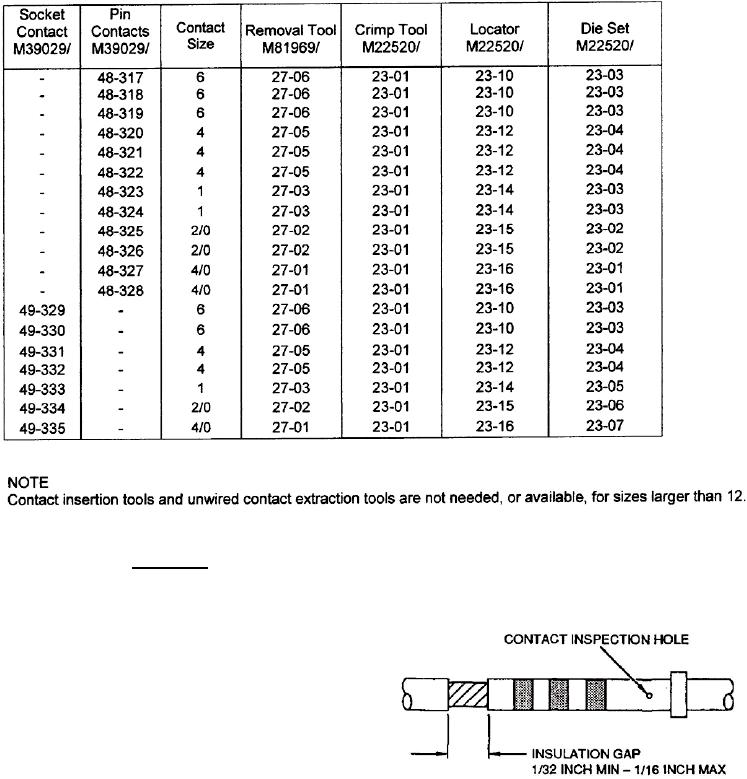

Table 7. MIL-DTL-22992 Connector Tooling

CAUTION

When removing broken wire contacts ensure

wire sealing grommet is not damaged. A new

connector must be installed (Paragraph 55) if a

broken wire contact cannot be removed.

b. Perform die closure check. Install positioner

and set selector knob for gage of wire.

c.

Insert stripped wire into contact conductor

barrel. Ensure all wire strands are inside contact

conductor barrel and visible in contact inspection hole

(Figure 20).

Figure 20. Insulation Gap Inspection

d. If insulation gap is too large, trim conductor

as required. If insulation gap is too small, trim

insulation as required (NAVAIR 01-1A-505-1,

WP 009 00).

e.

Crimp contact to wire.