NAVAIR 01-1A-505-2

011 02

TO 00-25-255-1

Page 3

TM 1-1500-323-24-2

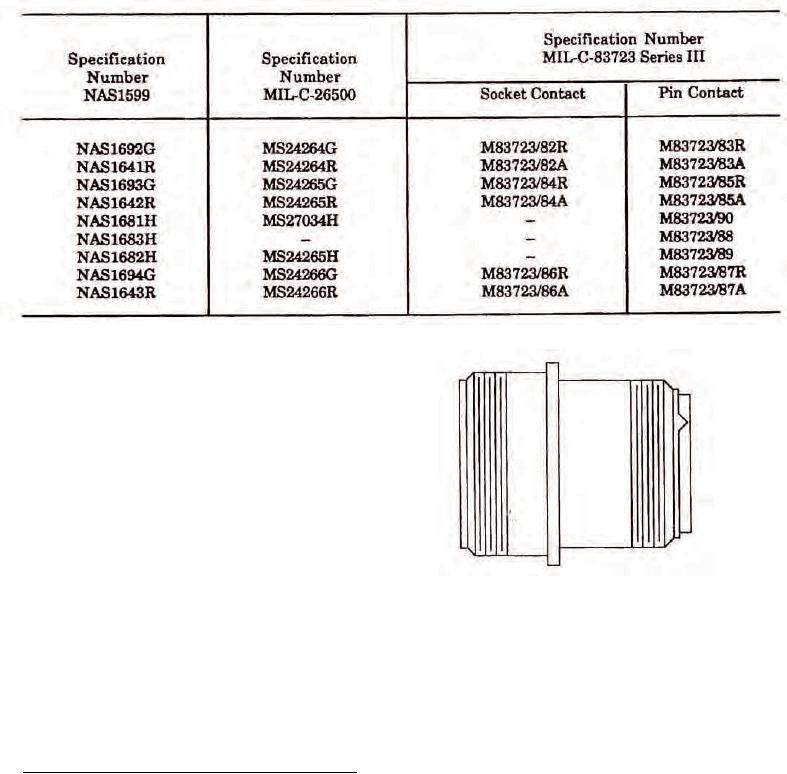

Table 1. Threaded Coupled Connector Intermatabilty Cross-Reference

connectors, provided the insert configurations are the

same. Table 1 provides an intermateability cross-

reference from threaded type connectors covered by

NAS1599 to MIL-DTL-26500 and MIL-C-83723 Series

III connectors.

5. The entire assembly process is performed at rear of

connector so that the possibility of damaging critical

interface of connector is greatly reduced. This rear

release feature also permits the removal or installation

of any number of contacts without uncoupling

connector.

6. WIRE SEALING. Wire sealing is accomplished by

Figure 1. NAS1599 Threaded Coupled

use of a grommet seal designed to seal against outside

Typical Connector

diameter of inserted wire. The outer diameter shall be

within applicable size range.

when ordered as a unit will have sealing plugs enclosed

NOTE

to equal 15 percent of the number of contacts but not

less than one.

Unwired contacts must have sealing plugs

installed.

10. MATING SEAL Plugs and receptacles with pin

7. NAS1599 THREADED COUPLED CONNECTOR.

inserts have a resilient face with individual pin barriers

to seal against the bard face socket insert. The resilient

8. Threaded coupled type connectors, NAS1599,

interface seal provides individual contact seals in mated

conform to MIL-DTL-26500 insert configuration, but

condition between each contact and shell.

utilize crimp rear release contacts and hermetic non-

removable solder contacts (Figure 1).

11. SHELL. Shells including mounting flanges are of

one-piece construction and designed to retain their

9. GROMMET SEALING PLUGS. The grommets of

inserts in one position by mechanical means. Each plug

environment resisting connectors are designed to accept

and receptacle has at least one blue color band, which

sealing plugs in accordance with NAS1599 to be used

indicates rear release retention system, and is located

where unwired contacts are placed. The connector

to be readily visible.