NAVAIR 01-1A-505-2

011 02

TO 00-25-255-1

Page 14

TM 1-1500-323-24-2

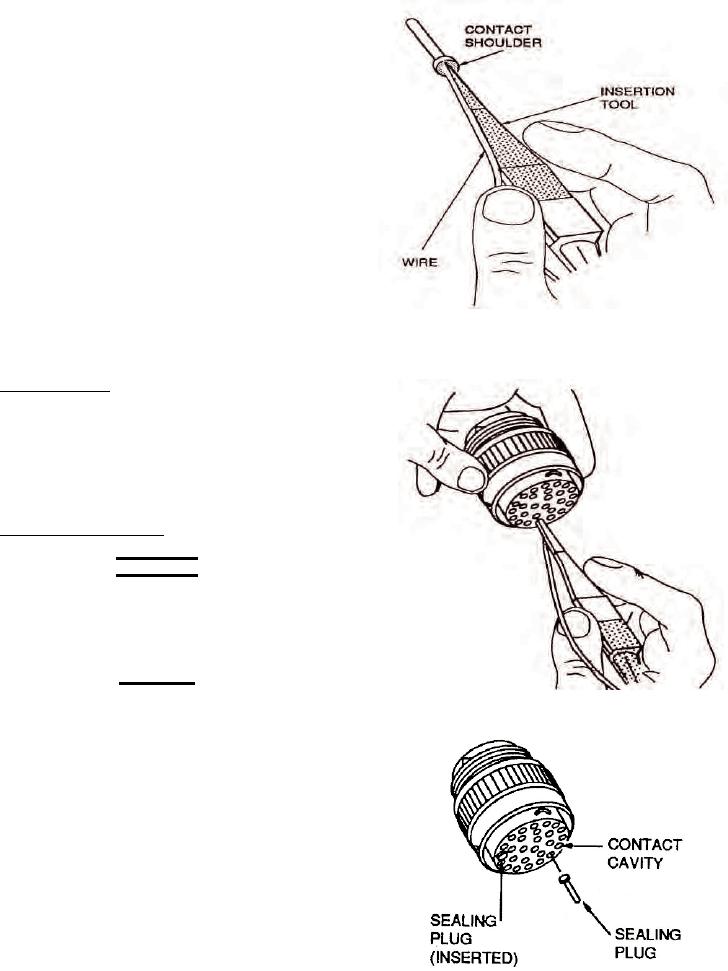

h. Pull tool straight out of contact cavity. Remove

tool from wire. Pull back lightly on wire to ensure

contact is property seated.

i.

Seal connector as required (Paragraph 90) and

install backshell.

90. CONNECTOR SEALING.

91. Sealing Plugs. Seal connector in accordance with

following procedure:

a. Fill all unused cavities with un-crimped

contacts (Paragraph 89).

b. Insert sealing plug, large diameter first, until

bottomed in contact cavity (Figure 12). Fill all cavities

Figure 10. Inserting Contact Into Insertion Tool

that have un-crimped contacts. Preserve connector in

accordance with NAVAIR 01-1A-505-1, WP 026 00.

92. Moisture Barrier. For connector sealing procedures,

including application of sealant to grommet sealed

connectors, refer to NAVAIR 01-1A-505-1, WP 025 00.

93. CONTACT REMOVAL. Remove wired, unwired,

and broken wire contacts in accordance with following

paragraphs.

94. Wired Contact Removal.

WARNING

Metal tool tips are sharp and can cause injury

to personnel and/or damage to connectors.

Exercise caution when using this tooling.

CAUTION

Figure 11. Contact Insertion

Metal tooling may damage the wire sealing

grommet at the end of the connectors. Use of

plastic tools is preferred.

a.

Select removal tool (Table 4).

b. Inspect tips of metal tools for nicks, burrs, and

distortion of probe before use as connector damage can

occur.

c.

Place wire of contact to be removed into

removal tool, with white tip facing connector insert

(Figure 13).

Figure 12. Inserting Sealing Plug into Contact Cavity