NAVAIR 01-1A-505-3

TO 1-1A-14-3

TM 1-1500-323-24-3

009 02

1 September 2011

Page 7

18. CONNECTOR BUILDUP.

19. For additional detailed information concerning

soldering procedures and solder type connectors refer

The use of lead-free solder in place of tin-

to NAVAIR 01-1A-505-1, WP 016 00.

lead solder is expressly prohibited as part of

any of the repair processes addressed

20. UNSOLDERING CONDUCTOR WIRE

throughout this technical manual. Any

FROM CONTACT.

contamination of a lead-free assembly with

tin-lead solder may significantly reduce the

WARNING

reliability of the assembly.

Use extreme care not to damage contacts or

Safety glasses shall be worn during all wire

adjacent wires.

cutting, stripping, and soldering operations.

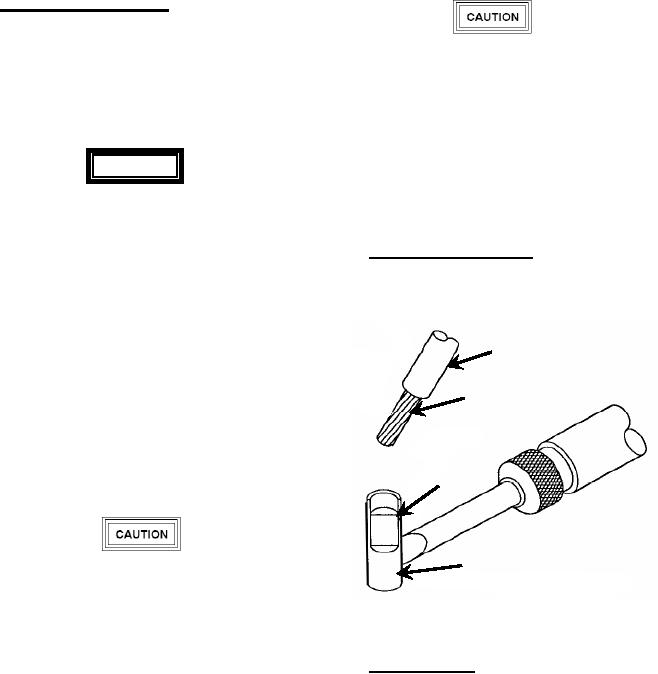

21. Removing Conductor Wire. Apply heat to solder

Solder contains lead and other hazardous

cup using soldering iron until solder melts; then

materials. Avoid oral contact with hands

remove wire (Figure 3).

during soldering operations and always wash

hands immediately after soldering.

Insulation

Become familiar with Material Safety Data

sheets (MSDS) for all materials used and use

proper personal protection equipment (PPE).

Conductor

Under no circumstances will either acid flux

or inorganic chloride flux, whether as liquids

or as flux-core solders, be used for securing

connections on electrical or electronic

Solder

equipment.

Contact Solder

When heating contacts of DEJ-9MS

connectors, a heat sinking device must be

attached to the solder cup of the connector

Figure 3. Conductor Wire Removal

contact. Failure to do so can result in

damage to the connector filter.

22. Removing Solder.

Repair of lead-free circuit cards is NOT

a. Remove solder from solder cup by wicking

permitted.

with a stranded conductor or braided shield and liquid

flux.

b. When wicking with stranded conductor or

braided shield place wire on soldered connection and

apply heat using soldering iron (Figure 4).