NAVAIR 01-1A-505-3

TO 1-1A-14-3

TM 1-1500-323-24-3

009 02

1 September 2011

Page 9

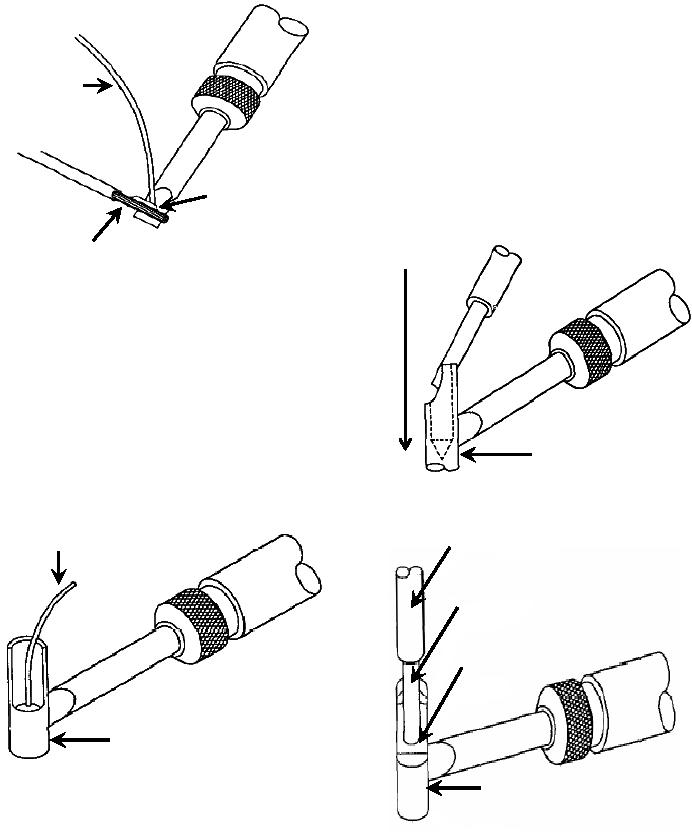

d. While maintaining contact solder cup at

soldering temperature, insert wire into contact solder

cup and slide heat source to base of contact solder cup

(Figure 8).

e. Ensure wire is bottomed in contact before

Solder

soldering iron is removed (Figure 9).

f. After solder cools, it shall form a fillet

extending from conductor to tip of solder cup (Figure

10).

Tin Wire For

Slide Soldering

One-Half

Iron Down

Stripped

When Wire Is

Stripped End

Inserted

Figure 6. Tinning Wire using Soldering Iron

24. SOLDERING HOLLOW CUP

CYLINDRICAL CONTACT.

a. Position connector at an angle with the open

end of cup toward the technician. Ensure wire to be

soldered is routed through connector backshell.

Contact Solder Cup

b. Direct soldering iron at contact solder cup

until solder flows (Figure 7).

Figure 8. Inserting wire into Solder

Solder

Insulation

Wire

Solder

Contact Solder Cup

Contact Solder

Figure 7. Filling Solder Cup with Solder

c. Pre-fill contact solder cup with enough solder

to ensure that total of pre-filled solder and pre-tinned

Figure 9. Wire Inserted into Contact

wire will fill cup without overflowing when wire is

inserted.