NAVAIR 01-1A-505-3

TO 1-1A-14-3

TM 1-1500-323-24-30

13 02

1 September 2011

Page 19

a. Clamp appropriate wafer into wafer retainer

g. Using an approved heater, direct hot air at the

(Figure 11, detail A or B).

solder until it melts and flows, detail D.

b.

Strip wire to be terminated as shown in detail

h. When installing clamp or restraining bar,

C.

apply thread-locking compound, MIL-S-46163A,

grade J, to captive screws prior to installation.

c. Install a connector sealing insert as shown in

detail D. When terminating shielded cable, first install

NOTE

shield termination sleeve and then install conductor

termination sleeve, detail G.

Allow solder to cool before disturbing.

d. Slide a solder sleeve termination over wire to

i. Shielded wire shields are soldered to the

be connected with the preinstalled seal ring located

shield bus bar, detail G.

away from the wafer, detail D.

j. Remove reflector shield and verify the

e. Position the stripped wire end as shown and

following conditions as shown in detail F. Also, see

slide solder sleeve termination to contact wafer body,

Table 2 and Table 3 for corrective action.

detail D.

k. Insert wafer in rear of MTC shell, observing

f. Construct a reflector shield from aluminum

proper keying, detail J.

tape or foil and position behind the tab being

connected and in front of all other tabs, detail E.

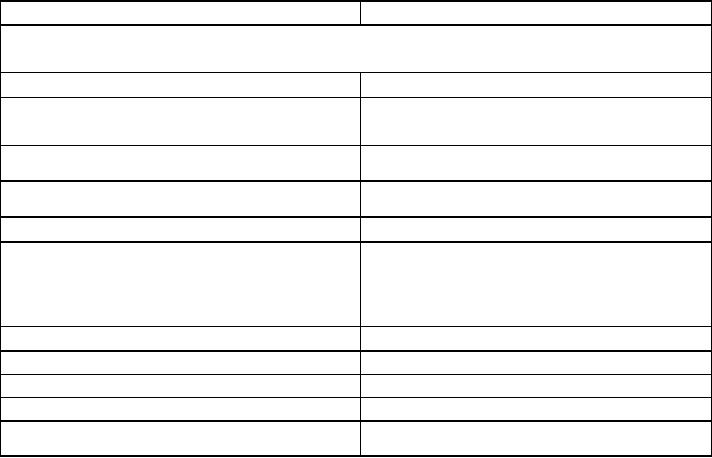

Table 2. Correction of Unacceptable Solder Conditions

UNACCEPTABLE CONDITION

CORRECTIVE ACTION

NOTE Isolate terminal with foil before reheating.

End of wire not in cupped area of the wafer terminal

Reheat and pull wire strands into the cupped area

Conductor end or strands can be seen along the side of

Reheat and pull wire strands into the cupped area of the

the terminal from the backside of the wafer

terminal

Conductor not overlapping the terminal at least 0.080

Reheat and push wire farther onto terminal

inch

Conductor overlapping terminal beyond the cupped area

Reheat and pull wire back into the cupped area

Sealing inserts not melted or sleeving not shrunk

Reheat until inserts melted and sleeving fully shrunk

Reheat and push wire farther into sleeving unless this

would cause the wire strands to extend past the cupped

Sleeving overlapping insulation less than 0.040 inch

area of the terminal. Otherwise, remove the sleeving,

re-strip the wire, and re-solder with a new solder sleeve

Sleeving farther from wafer body than 0.040 inch

Remove sleeve and re-solder with a new solder sleeve

Solder ring discernible

Reheat

Solder fillet not discernible

Replace the solder sleeve

Sleeving too brown to see joint

Replace the solder sleeve

Replace the solder sleeve. Smooth or re-strip wire

Wire strands penetrating or protruding into the sleeving

before re-soldering