NAVAIR 01-1A-505-3

TO 1-1A-14-3

TM 1-1500-323-24-30

13 02

1 September 2011

Page 20

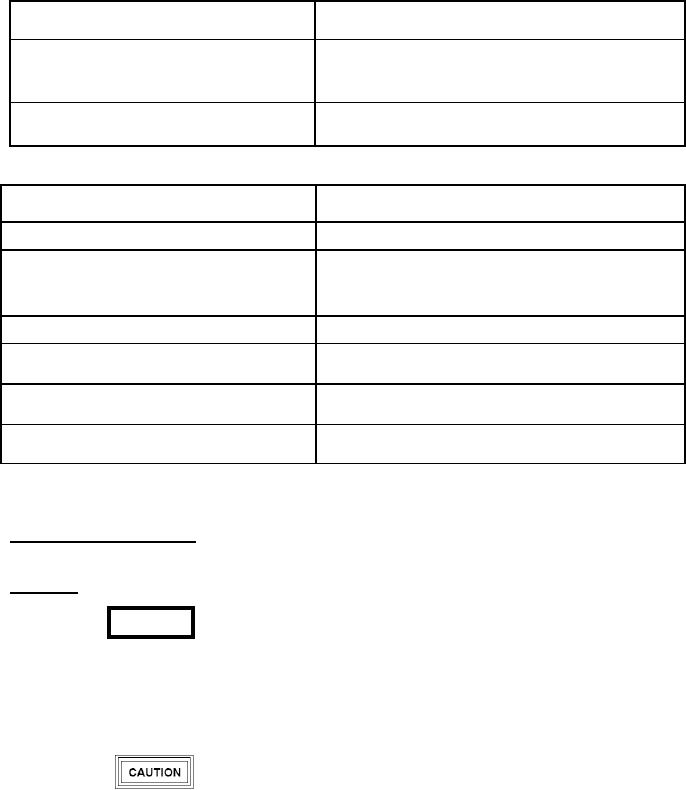

Table 2. Correction of Unacceptable Solder Conditions (Continued)

UNACCEPTABLE CONDITION

CORRECTIVE ACTION

Reheat and pull wire back until the insulation is clear of

Insulation overlapping area of the terminal

the cupped area. Insulation can be against the terminal

but not on it

Reheat and adjust wire toward the terminal until the

Insulation gap exceeds 0.45 inch

insulation gap is acceptable

Table 3. Corrective Actions for Unacceptable Shield Bus Bar Terminations

UNACCEPTABLE CONDITION

CORRECTIVE ACTION

Shield not overlapping bus tab at least 0.20 inch

Reheat and reposition shield

Solder ring still discernible or fillet not formed

Reheat until preform flows, loses ring shape, and wets the

between shield and bus tab

shield and tab

Sleeve so dark that joint is not discernible

Replace solder sleeve

Fillet not discernible between shield and tab due

Replace solder sleeve

to wicking

Shield braiding puncturing or protruding into

Remove sleeve; smooth braiding. Re-solder with new

sleeve

sleeve

Remove sleeve, replace wire as necessary, and re-solder

Sleeve or insulation burned or damaged

with new sleeve

43. CONNECTOR COUPLING. Mating connectors

engage at even a minimum angle may result in

must be correctly aligned and securely attached.

damage to the pins.

44. Alignment.

a. Alignment consists of matching the key and

keyway (remove dust covers to see key and/ or

WARNING

keyways). Before positioning the mating connectors

together, check key and keyway alignment (Figure 11,

Before coupling connectors, insure that all

detail J) and ensure their correct positioning.

related circuits, including battery power, are

de-energized and applicable circuit breakers

b. On a wafer connector, the A-wafer pins go

are open to prevent severe shock or death to

into a wafer sockets. Also, the keys must mate. On

personnel.

wafer connectors, the keys are plastic inserts which

can be keyed (Figure 11, detail J) when installing new

connectors.

c. Wafer connectors mate by pushing the

correctly aligned plug into the receptacle. The

Insure that pins are straight before inserting a

matched joint is secured with screws and nuts on the

plug into a receptacle; forcing the plug to

sides of the connectors. Spacers may be added or