NAVAIR 01-1A-505-3

TO 1-1A-14-3

TM 1-1500-323-24-3

014 02

1 September 2011

Page 9

15. EPXB CONNECTORS.

tooling are controlled under military or SAE

specifications.

16. EPXB connectors have larger shells and are

available in aluminum with a electrolytic nickel over

19. DESIGN AND CONSTRUCTION. The

connectors and accessories are designed and constructed

electroless nickel finish or composite with nickel

to withstand normal handling during installation and

plating. They are available with inserts that

maintenance.

accommodate a maximum 48, size 22 contacts (Shell

Size 1) or a maximum 96, size 22 contacts (Shell Size 2).

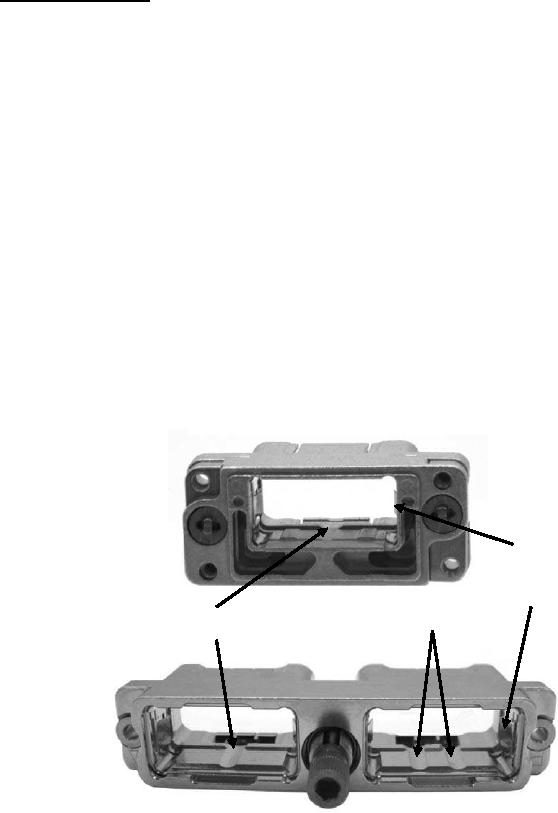

20. INSERTS. The entire insert of the EPXB assembly

is an individual part designed to suitable support around

17. PART NUMBER. EPX connectors have

the wires and sealing (for class E inserts, see Figure 11),

interchangeable inserts the connector shell and insert

and is removable/replaceable with different

must be ordered separately. The part number contains the

configurations of inserts. The inserts align with the

information necessary for the proper selection and

connector shell by a keyway. EPXB 1 uses keyway A

procurement (Figure 9 and 10).

and EPXB 2 uses keyway A on one side and keyway B

on the other as shown in Figure 8. Ordering and

18. MILITARY SPECIFICATION. The EPX

configuration information is contained in Figures 11, 12

connectors are a commercial series and therefore do not

and Table 1).

have a military specification. Some of the contacts and

EPXA and EPXB 1

Insert

Retention

Clips

Keyway B

Keyway A

EPXB 2

Figure 8. EPXA and EPXB Shell to Insert Keying