NAVAIR 01-1A-505-3

TO 1-1A-14-3

TM 1-1500-323-24-3

014 02

1 September 2011

Page 11

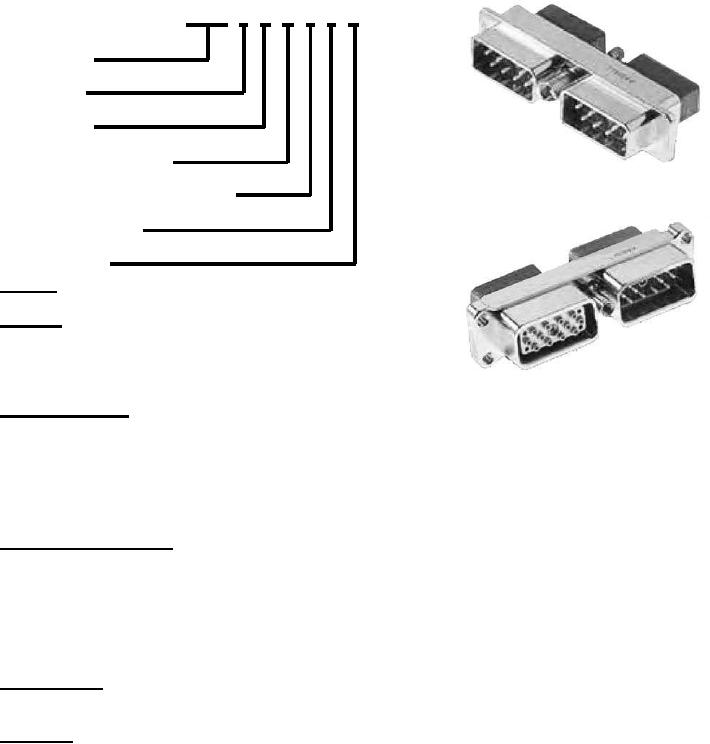

EPXB 2 P B 1 2 N

EPXB Type

Shell Size

Shell Style

Shell Mounting Option

Plug

Locking & Polarization Device

Polarization Code

Shell Plating

Shell Size

2 Number of insert locations

Shell Style

L Receptacle with flange and grounding fingers

P Plug (Without Grounding Block)

R Receptacle (Without Grounding Block)

W - Plug (With Grounding Block)

Z Receptacle (With Grounding Block and ground fingers)

Receptacle

Shell Mounting Option

A - Panel rear mounted connector

(With 4 X 6-32 mounting holes)

B No Mounting Holes

(Locking & Polarization codes 4 & 5 not available)

CAUTION

D Connector with 2 X 3.10 mm thru holes

EPX A and B aluminum shells are electrolytic nickel over

F Panel rear mounted connector

electroless nickel finished. These parts do not meet the

(With 2 X 6-32 mounting holes)

minimum salt fog test required for military use. If installed

L Panel rear mounted connector

additional inspection and corrosion prevention measures

(With 2 X 4-40 mounting holes)

are required to maintain system integrity. Platform

Locking & Polarization Device

Cognizant Engineering Authority (CEA) must use accepted

1 Jackscrew

Reliability Centered Maintenance (RCM) methods to

2 Jacknut

determine correct inspection cycle and correct treatment

(Jackscrew/jacknut can be mounted on plug or receptacle, standard configuration is

interval.

Jackscrew on plug, Jacknut on receptacle.)

3 Without locking device (cancels polarization code)

4 Pin polarization guide for rack and panel application

5 - Socket polarization guide for rack and panel application

(Pin/Socket polarization guides can be mounted on plug or receptacle. However, the

standard configuration pin polarization on plug and socket on receptacle.)

Polarization Code

2 Polarization device A to F delivered unassembled

3 - Polarization device N to Z delivered unassembled

Shell Plating

N Electroless Nickel (96 hour Salt Spray)

Refer to specification for current engineering details.

Figure 10. EPXB Shell Size 2 Shell Part Number Breakdown