NAVAIR 01-1A-505-3

TO 1-1A-14-3

TM 1-1500-323-24-3

014 02

1 September 2011

Page 10

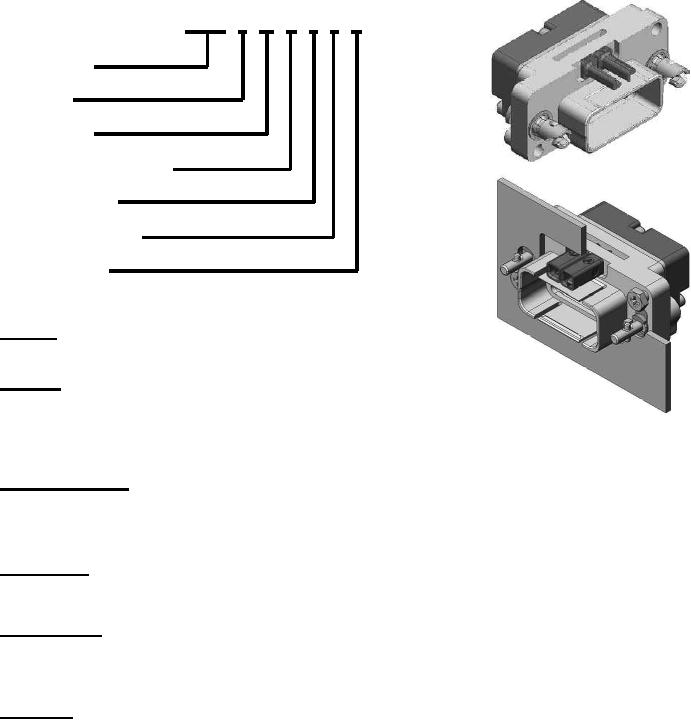

EPXB 1 W B 0 5 K

EPXB Type

Shell Size

Shell Style

Shell Mounting Option

Plug

Locking Device

Polarization Code

Shell Plating

Shell Size

1 Number of insert locations

Shell Style

P Plug (Without Grounding Block)

Receptacle

R Receptacle (Without Grounding Block)

W - Plug (With Grounding Block)

Z Receptacle (With Grounding Block and ground fingers)

CAUTION

EPX A and B aluminum shells are electrolytic nickel over electroless

Shell Mounting Option

B No Mounting Holes

nickel finished. These parts do not meet the minimum salt fog test

M Panel rear mounted connector

required for military use. If installed additional inspection and

(With 2 X 6.32 mounting holes)

corrosion prevention measures are required to maintain system

integrity. Platform Cognizant Engineering Authority (CEA) must use

accepted Reliability Centered Maintenance (RCM) methods to

determine correct inspection cycle and correct treatment interval.

Locking Device

0 Quarter Turn Fastener

Polarization Code

4 Shell delivered with polarization hardware unassembled

5 - Shell delivered with no polarization hardware

Shell Plating

M Nickel plated composite

K Electroless Nickel (96 hour Salt Spray)

Refer to specification for current engineering details.

Figure 9. EPXB Shell Size 1 Shell Part Number Breakdown