TM 1-1510-262-10

(4) Fuel crossfeed switch. The fuel crossfeed valve is controlled by a 3-position switch (Fig. 2-25),

located in the fuel management panel, placarded CROSSFEED OFF . During normal light conditions, the switch

is left in the OFF position. During emergency single engine operation, it may become necessary to supply fuel

to the operative engine from the fuel system on the opposite side. The crossfeed system is placarded for fuel

selection with a simpliied diagram on the overhead fuel control panel. STANDBY PUMP switches shall be in

the off position when crossfeeding. A lever lock switch, placarded CROSSFEED , is moved from the center OFF

position to the left or right, depending on direction of fuel low. This opens the crossfeed valve and energizes the

standby pump on the side from which crossfeed is desired. During crossfeed operation with irewall fuel valve

closed, auxiliary tank fuel will not crossfeed. When the crossfeed mode is energized, a green FUEL CROSSFEED

annunciator on the caution/advisory panel will illuminate. Crossfeed system operation is described in Chapter 9.

The crossfeed valve is protected by a 5-ampere circuit breaker placarded CROSSFEED located on the overhead

circuit breaker panel (Fig. 2-12).

f. Firewall Shutoff Valves.

Do not use the fuel irewall shutoff valve to shut down an engine, except in an emergency. The

engine-driven high- pressure fuel pump obtains essential lubrication from fuel low. When an engine

is operating, this pump may be severely damaged (during cavitations) if the irewall valve is closed

before the condition lever is moved to the FUEL CUTOFF position.

The fuel system incorporates a fuel line shutoff valve mounted aft of each engine irewall. The irewall shutoff valves

close when the ire extinguisher T handles on the instrument panel are pulled out. The irewall shutoff valves receive

electrical power from the main buses, and also from the hot battery bus which is connected directly to the battery.

The valves are protected by 5-ampere circuit breakers placarded FIREWALL VALVE #1 or #2 on the overhead

circuit breaker panel (Fig. 2-12), and FIREWALL SHUTOFF #1 or #2 on the hot battery bus circuit breaker board.

g. Fuel Tank Sump Drains. A sump drain wrench is provided in the aircraft loose tools to simplify draining a

small amount of fuel from the sump drain.

(1)

There are ive sump drains and one ilter drain in each wing (Table 2-3).

(2) An additional drain for the extended range fuel system line extends through the bottom of the wing

center section adjacent to the fuselage. Any time the extended range system is in use, a part of the prelight

inspection would consist-of draining a small amount of fuel from this drain to check for fuel contamination. When-

ever the extended range system is removed from the aircraft and the fuel line is capped off in the fuselage, the

remaining fuel in the line shall be drained.

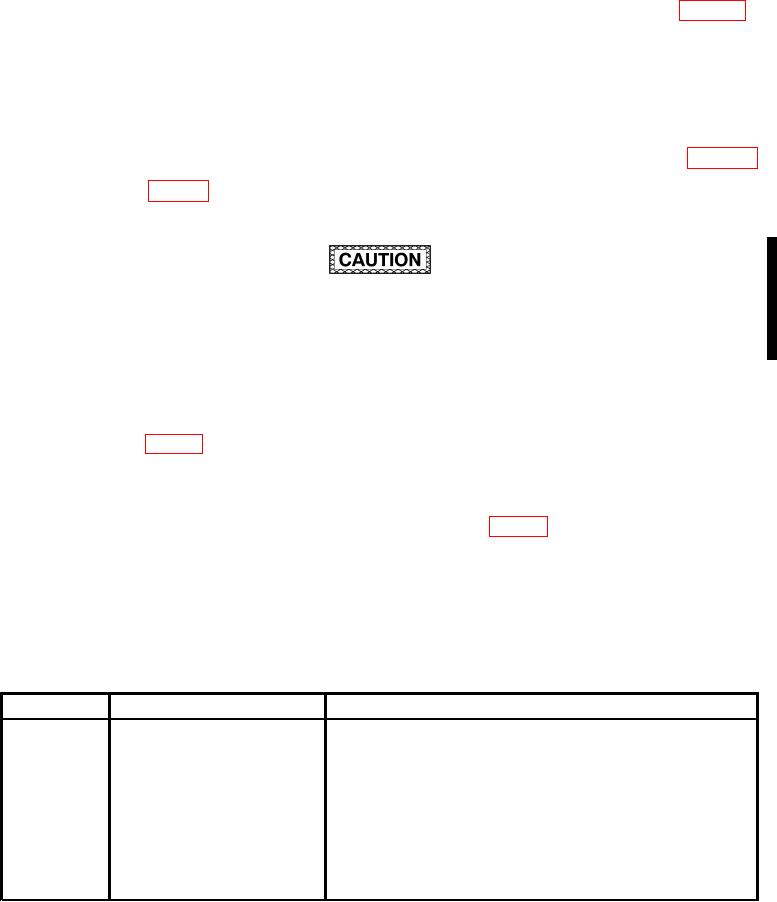

Table 2-3.

Fuel Sump Drain Locations

NUMBER

DRAINS

LOCATION

1

Leading Edge Tank

Outboard of nacelle, underside of wing

1

Integral Tank

Underside of wing, forward of aileron

1

Firewall Fuel Filter

Underside of cowling forward of irewall

1

Sump Strainer

Bottom center of nacelle forward of wheel well

1

Gravity Feed Line

Aft of wheel well

1

Auxiliary Tank

At wing root, just forward of the lap

1

Extended Range

Outboard of fuselage on underside of wing center section

BT00195

Change 1