TM 10-4930-351-14

0100 00

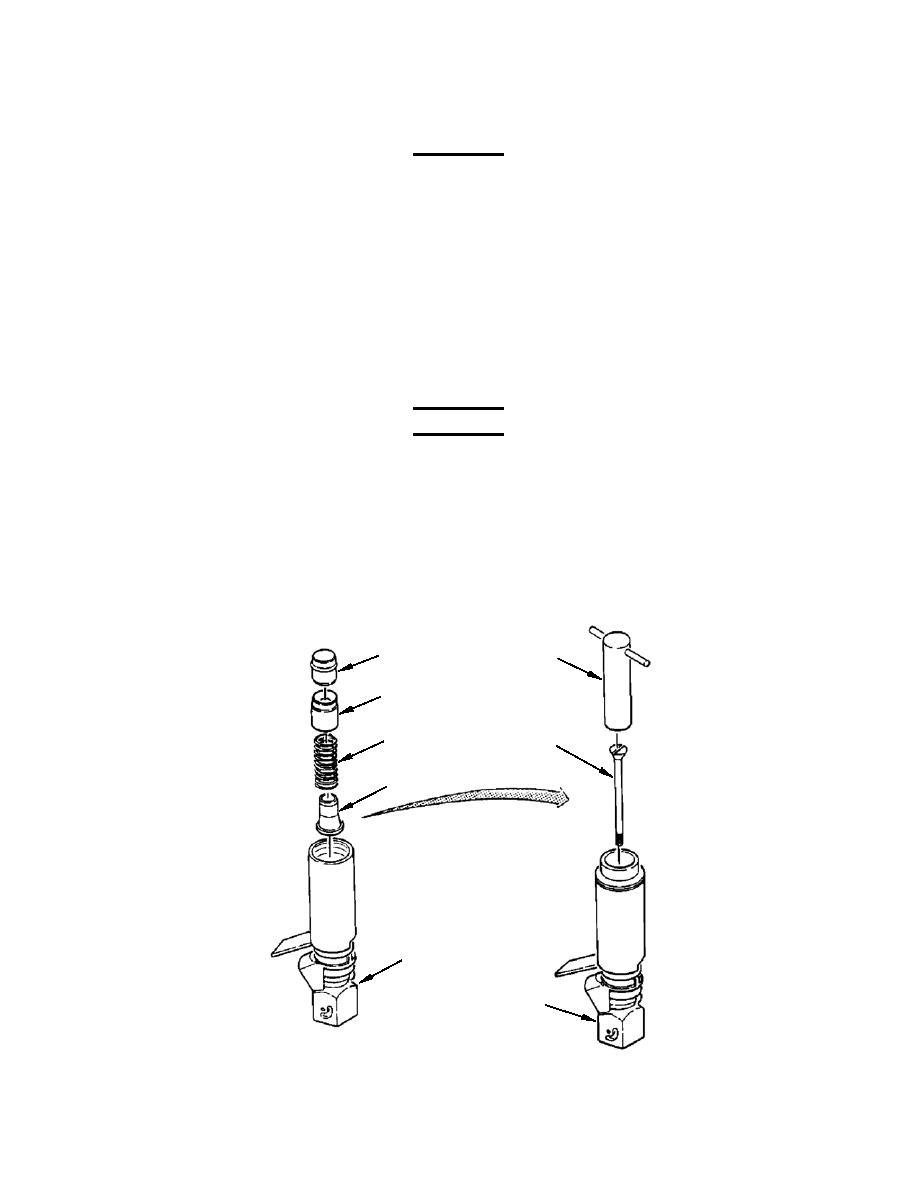

ASSEMBLY-Continued

CAUTION

To reduce the friction between locking lugs and collar, pull back slightly on the

collar.

NOTE

Always align the slot in the collar and the tab on the housing.

20. Tighten and torque the assembly to 250 in. lbs.

21. Pull back on the collar (27) to release the body wrench, remove body wrench. Remove nozzle assembly from vise.

22. Insert flow guide (31), spring (28) and sleeve seal (30) into nozzle housing (14).

WARNING

During assembly the components; spring, flow guide and sleeve seal will be under

spring pressure. Do not push or pull collar to the rear. Do not remove compression

tool until assembly is completed. Personal injury could result.

23. Using compression tool push sleeve seal (30) and spring (28) into nozzle housing (14) until compression tool locks in

collar (27).

24. Insert poppet (29) through compression tool into nozzle housing (14).

POPPET

COMPRESSION

WRENCH

TOOL

30

29

28

31

14

14

0100 00-12