TM 10-4930-351-14

GENERAL SUPPORT MAINTENANCE

ADVANCED AVIATION FORWARD AREA REFUELING SYSTEM MODEL M100A1

ENGINE ASSEMBLY

Follow good engineering practice during engine assembly. Clean and inspect all parts before assembly. Replace any part

which is damaged or out of tolerance. Use assembly lube (WP 0116 00, Item 3) or equivalent on all mechanical parts to

prevent damage during first start of reassembled engine. Clean oil passages in block and all components before assembly.

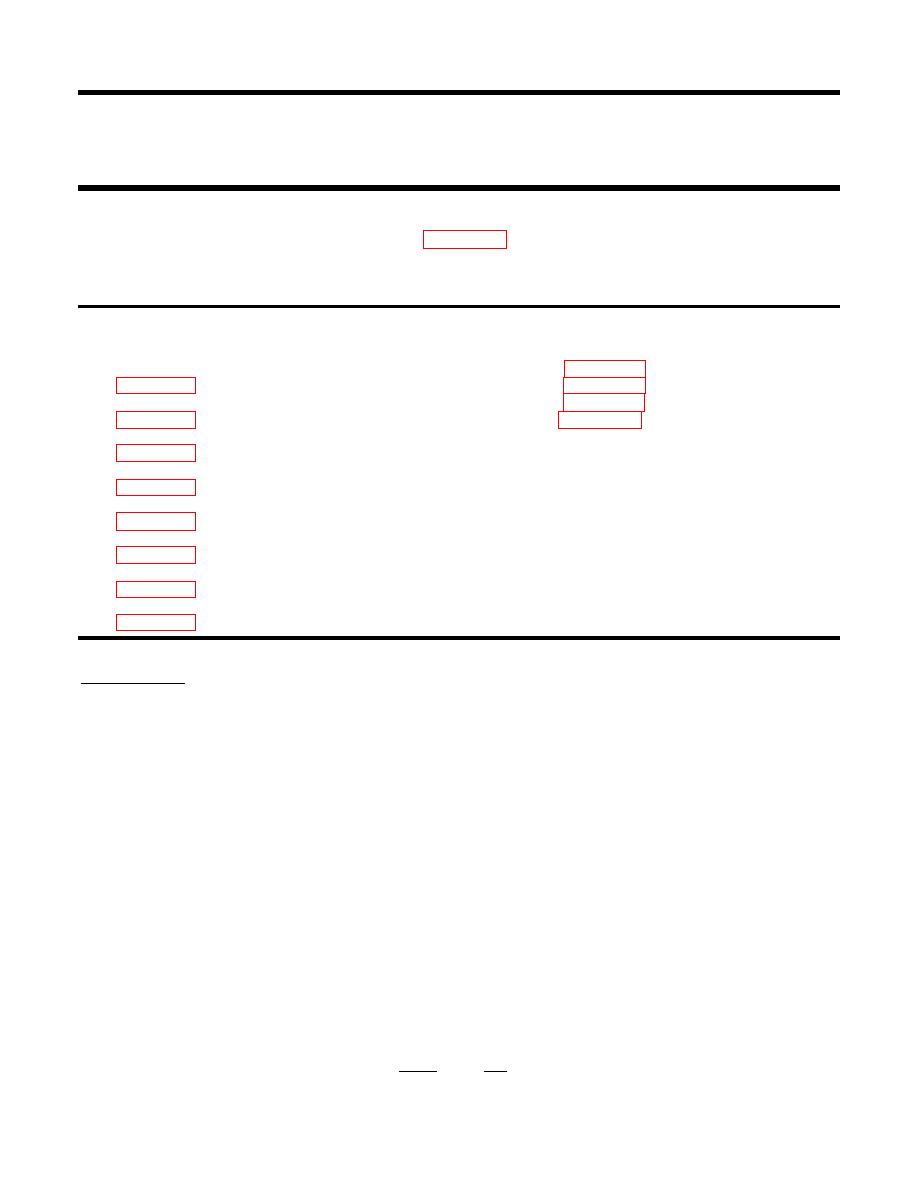

INSTALL CRANKSHAFT AND REAR CRANKSHAFT SUPPORT (Refer to Figures 1, 2 and 3.)

INITIAL SET-UP:

Tools:

Materials/Parts Required

Screwdriver, Flat Blade

Oil Seal (WP 0117 00, Item 37)

(WP 0113 00, Item 3)

Bearing (WP 0117 00, Item 39)

Thickness Gauge, 0.006

Bearing (WP 0117 00, Item 40)

(WP 0113 00, Item 3)

O-Ring (WP 0117 00, Item 55)

Wrench, Torque, 0-300 in. lb

(WP 0113 00, Item 3)

Extension, 6 in., 3/8 in. drive

Equipment Condition:

(WP 0113 00, Item 3)

Crankshaft removed

Socket, Socket Wrench, 6 mm

Rear crankshaft support removed

(WP 0113 00, Item 3)

Gloves, Welder

(WP 0113 00, Item 3)

Remover, Bearing and Bushing

(WP 0113 00, Item 6)

Central Bearing Assembly Tool

(WP 0113 00, Item 7)

Refer to Figure 1.

1.

Temporarily reassemble the two halves (1) of the center crankshaft bearing support. Check for excessive wear of the

center crankshaft bearing support as follows. If any measurement is out of tolerance, replace the bearing support.

a.

Measurement A (Bearing Support Outer Diameter): 4.645-4.646 in. (117.99-118.01 mm).

b.

Measurement B (Bearing Support Inner Diameter): 1.888-1.889 in. (47.965-47.985 mm).

c.

Measurement C (Bearing Support Thickness): Not less than 1.06 in. (27 mm).

2.

Measure diameter of crankshaft main journal, the two end journals and the two connecting rod journals. Measure again

at points that are 90 from first measurement. Use the smaller of the two numbers for each measurement. Check for

excessive wear in accordance with the following. If any measurement is out of tolerance, replace the crankshaft.

a

Measurement D (Main and End Journals): 1.772-1.769 in. (45.01-44.93 mm).

b

Measurement E (Connecting Rod Journals): 1.575-1.572 in. (40.005-39.925 mm)

3.

Install crankshaft bearing halves (2) in center bearing support halves (1).

4.

Line up the matching reference numbers on the center bearing support halves (1) and install the center bearing support

halves around the crankshaft (3).

5.

Install two 6 mm crankshaft support screws (4).

6.

Torque crankshaft support screws to 190 to 195 in. lbs (21-23 Nm).

0109 00-1