TM 10-4930-351-14

GENERAL SUPPORT MAINTENANCE

ADVANCED AVIATION FORWARD AREA REFUELING SYSTEM MODEL M100A1

OVERHAUL FUEL TRANSFER PUMP PN 60975-7

INITIAL SET-UP:

Materials/Parts Required:

Tools:

Anti-Seize Compound, Molybdenum Disulfide

Wrench, Combination, 1/2"

(WP 0116 00, Item 6)

(WP 0113 00, Item 1)

Petrolatum (WP 0116 00, Item 20)

Wrench, Combination, 7/16"

O-Ring (WP 0117 00, Item 70)

(WP 0113 00, Item 1)

O-Ring (WP 0117 00, Item 71)

Key, Socket Head Screw, 9/64"

O-Ring (WP 0117 00, Item 73)

(WP 0113 00, Item 1)

O-Ring (WP 0117 00, Item 75)

Key, Socket Head Screw, 3/16"

O-Ring (WP 0117 00, Item 76)

(WP 0113 00, Item 1)

O-Ring (WP 0117 00, Item 77)

Strap Wrench (WP 0113 00, Item 3)

O-Ring (WP 0117 00, Item 79)

Wrench, Combination, 9/16"

O-Ring (WP 0117 00, Item 80)

(WP 0113 00, Item 1)

Wrench, Combination, 1-5/8"

(WP 0113 00, Item 1)

Equipment Condition

Screwdriver, Flat Blade, 1/8"

Fuel transfer pump defueled

(WP 0113 00, Item 1)

Fuel transfer pump removed from pump-engine

Hammer, Ball Peen, 2 lb.

module (WP 0034 00)

(WP 0113 00, Item 2)

Quick disconnect fitting removed from pump

Torque Wrench, 0-300 in. lb.

(WP 0113 00, Item 2)

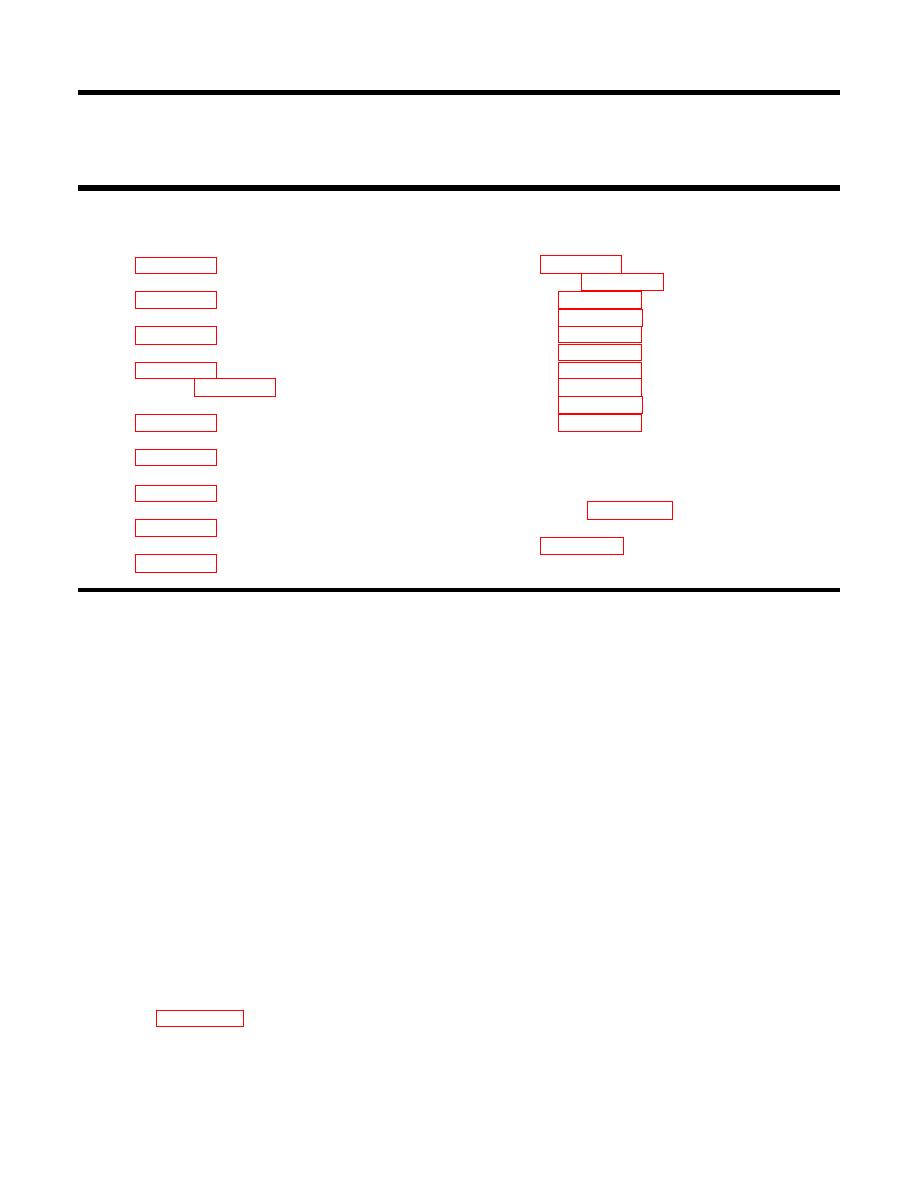

DISASSEMBLY

1.

Remove the three hex head screws (1) and flat washers (2) that secure the outlet (3) to the diffuser case (4). Lift the

outlet (3) off the diffuser case (4).

2.

Remove and discard O-rings (5) and (6).

NOTE

The flapper valve is a butterfly valve designed to open when fuel pump full flow has been attained. Before

disassembly, note the orientation of the springs on the valve body and the valve body position in the pump

outlet for assembly and installation. The springs appear to be identical when installed; the difference can be

seen only when the springs have been removed. The springs are properly installed when the flapper valve

matches the one shown in the figure inset. Use care not to lose any spacer when removing flapper valve

assembly.

3.

Remove flapper valve assembly (7, 8, 9, 10, and 11) by pushing down on outer pin (7) from the top, just enough so that

the top of the outer pin (7) clear diffuser case (4) top outer pin hole. Pull the top of flapper valve assembly out far

enough to push up on outer pin (7) from the bottom to clear diffuser case (4) bottom outer pin hole, using care not to

lose any of the six small spacers (9), remove flapper valve assembly. Inspect flapper valve assembly for damage.

Replace if damaged or otherwise unfit for use. Do not disassemble flapper valve (8) unless replacement is required.

Refer to WP 0088 00 for flapper valve disassembly and assembly.

0110 00-1