TM 55-2840-241-23

c. Installation.

(1) Install serviceable exciter on the engine and

secure with three nuts (4) and washers (5). Tighten

nuts (4) to 30-40 in. lb.

(2) Attach igniter lead (18) to the exciter.

Tighten coupling nut to 50-70 in. lb.

(3) Attach power input lead to the exciter input

terminal. Secure with washer (2) and nut (1). Tighten

nut to 8-12 in. lb.

5-36. Spark Igniter

a. Removal.

To prevent personnel injury due to elec-

trical shock ensure ignition system has

been off for at least five minutes before

removing igniter to dissipate all energy

stored in condenser. Ground igniter lead

to engine using an insulated screwdriver.

(1) Disconnect igniter lead (18, figure 5-16) at

igniter (19). Prevent lead from twisting while remov-

ing nut.

(2) Separate lead from igniter by pulling

straight out without any rotational motion.

(3) Remove lock wire and unscrew igniter (19).

The igniter connector well must be kept

dry and free from foreign material.

Damage to igniter and igniter load could

result.

b. Cleaning.

(1) Clean igniter connector well with a clean

dry cloth. Do not wash with solvent.

Under no circumstances, wire brush,

sand blast, vapor blast, or scrape the igni-

ter. Any of these cleaning methods can

damage the semi-conductor.

(2) Normal soot or carbon formation on the tip

is not detrimental to igniter operation and need not be

removed. If cleaning is desired, wipe the metal tip with

a soft dry cloth.

(3) Remove any sizable carbon deposits with a

blunt non-metallic instrument. Be careful not to

damage the semi-conductor material.

c. Inspection.

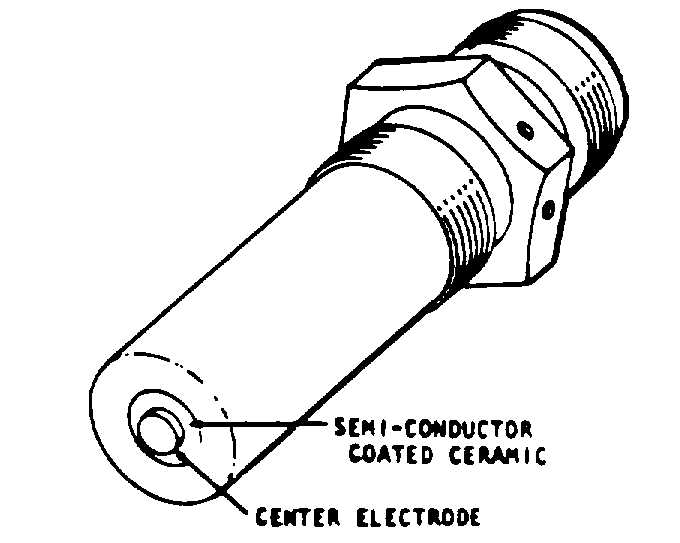

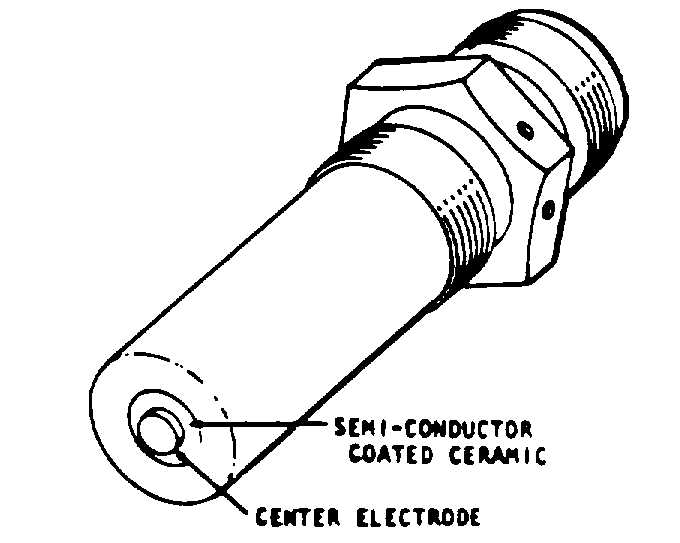

(1) Inspect center electrode; replace igniter if

electrode is loose (See figure 5-17.)

(2) Inspect ceramic for cracks; if any cracks are

visible through carbon coating, replace ignite.

4364A

Figure 5-17. Spark Igniter

d. Testing.

(1) With a good exciter and igniter lead, check

igniter operation before installing in engine.

(2) Apply 28 volts dc to the exciter; observe the

rate of firing. Normal operation is six sparks per second

minimum.

(3) Replace igniter if it fails to fire or fires inter-

mittently.

e. Installation.

(1) Apply a light coat of antiseize compound

(item 26, table 2-2) to the threads and install serviced

or new igniter; tighten to 150-200 in. lb. and lockwire

(item 10, table 2-2) to fuel nozzle.

(2) Connect igniter lead; tighten to 70-90 in. lb.

5-37. Spark Igniter Lead.

a. Removal.

To prevent personnel injury due to elec-

trical shock ensure ignition system has

been off for at least five minutes before

disconnecting igniter lead. Ground lead

to engine using an insulated screwdriver.

(1) Remove the lead (18, figure 5-16) from the

ignition exciter (3) and the spark igniter (19).

Change 23

5-27